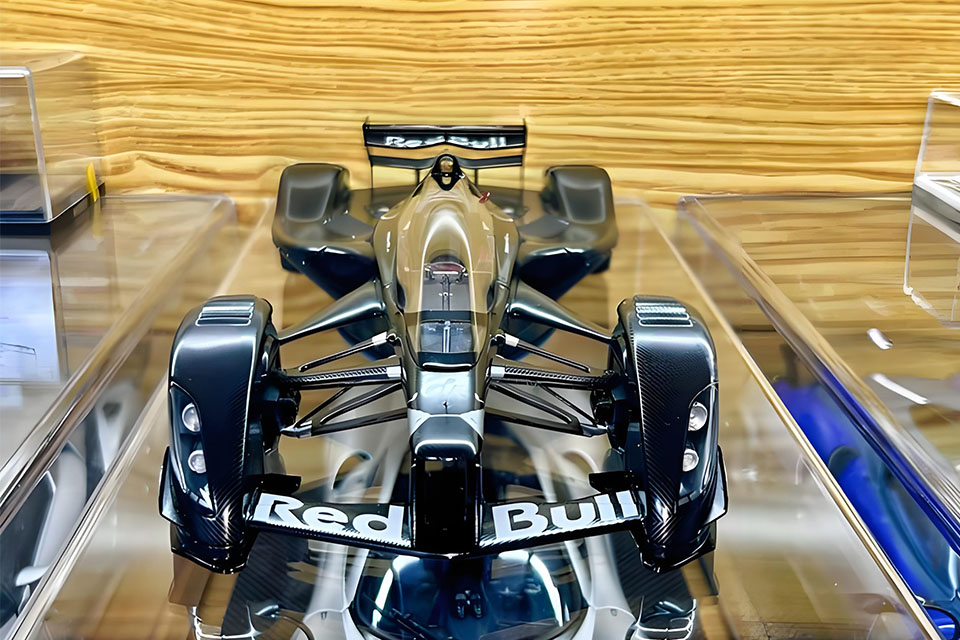

Wie Carbonfaser Rennwagen besser machte

Das große Problem mit alten Rennwagen

Rennautos war früher zu schwer. Große Metallautos waren langsamSie waren nicht sicher für Fahrer. Wenn Autos gegen Wände prallten, zerbrachen Metallautos auf schlimme Weise.

Die Fahrer wollten Autos, die schnell aber bleib sicher.

Die Teams probierten vieles aus. Sie probierten neues Metall aus. Sie probierten neue Formen aus. Aber die Autos waren immer noch zu schwerDie Autos brachen immer noch ein schlechte Wege.

Was wäre, wenn es eine Möglichkeit gäbe, Rennwagen deutlich leichter zu machen? Was wäre, wenn Autos selbst nach einem Unfall stabil bleiben könnten?

Warum das so schlimm war

Denken Sie an ein Rennauto, das zu viel wiegt:

- Es geht Langsamer auf geraden Straßen

- Es kann sich nicht drehen schnell in Kurven

- Es verwendet mehr Gas

- Es bricht weitere Teile

- Es versetzt Fahrer in mehr Gefahr

Jedes Rennteam versuchte, diese großen Probleme zu lösen. Doch alle stießen auf dasselbe Problem: Metall kann nur ein begrenztes Gewicht haben und trotzdem stabil bleiben.

Wenn Rennwagen verunglücken 200 Meilen pro Stunde, Metallautos klappen zusammen. Das bringt den Fahrer in große GefahrViele wurden verletzt. Einige haben es nicht geschafft.

Die Teams brauchten etwas viel besser als Metall.

Kohlefaser: Die große Lösung

Im Jahr 1981 etwas groß geschehen. Die Das McLaren-Team hat die erste vollständige Kohlefaser Rennwagen, der MP4/1.

Dieses neue Auto wurde hergestellt mit schwarze Saiten Das sind:

- 5 mal stärker als Stahl

- 40-50% Feuerzeug als Stahl

- Mehr sicher bei Abstürzen

Dies war der Beginn einer große Veränderung in Rennwagen.

Wie Kohlefaser alles veränderte

Mal sehen, wie Autos aus Kohlefaser geändertes Rennen:

| Was hat sich geändert? | Vor der Kohlefaser | Nach Carbonfaser |

|---|---|---|

| Gewicht | Schwermetallautos | 40-50% leichtere Autos |

| Geschwindigkeit | Langsamere Rundenzeiten | 1,5 Sekunden schneller pro Runde |

| Sicherheit | Viele schlimme Unfälle | 70% bessere Fahrersicherheit |

| Teile verwendet in | Nur ein paar Teile | Jetzt 75% des ganzen Autos |

Mit Carbonfasern können die Teams Autos bauen, die sowohl Licht Und starkAus diesem Grund verwenden alle F1-Teams jetzt Kohlefaser.

Warum Teams Carbonfaser lieben

Teams lieben Kohlefaser aus vielen wichtigen Gründen:

- Macht Autos schneller – Weniger Gewicht bedeutet mehr Geschwindigkeit

- Sorgt für die Sicherheit der Fahrer – Die Carbonfaserschale bleibt bei Stürzen stabil

- Kann jede beliebige Form annehmen – Teams können Teile in jeder gewünschten Form herstellen

- Hält lange – Teile verschleißen nicht schnell

- Sieht cool aus – Das schwarze Gewebe sieht auch im Stand schnell aus

Der McLaren MP4/1 zeigte, wie gut Kohlefaser ist. Der Fahrer hat einen schweren Unfall überstanden, der in einem Metallfahrzeug viel schlimmer gewesen wäre.

Das Kohlefaserproblem

Aber es gibt eine großes Problem mit Kohlefaser. Die Herstellung ist teuer. Die Herstellung erfordert viel Energie. Es ist schwer zu reparieren, wenn es kaputt geht.

Weitere Probleme mit Kohlefaser:

- Aus 1 kg werden 30 kg schlechte Luft

- Sehr schwierig, alte Teile wieder zu verwenden

- Benötigt große heiße Öfen zur Herstellung

- Es braucht viele Schritte, um es richtig zu machen

- Benötigt Top-Fähigkeiten, um gut zu sein

Rennteams wollen weiterhin Kohlefaser verwenden. Doch sie müssen diese gravierenden Probleme lösen.

Die neue Carbonfaser-Lösung

Die Teams arbeiten derzeit an neue Wege um Kohlefaser für unsere Welt besser zu machen.

Mercedes entwickelt für seinen Rennwagen W16 des Modelljahres 2025 eine neue Art von Kohlefaser. Diese neue Kohlefaser wird:

- Halten Sie Autos schnell und sicher

- Machen Sie weniger schlechte Luft

- Einfachere Wiederverwendung alter Teile

- Helfen Sie mit, unsere Welt zu verbessern

Diese neue Kohlefaser besteht aus zwei Hauptbestandteilen:

- 60%-Fasern (die schwarzen Saiten)

- 40%-Harz (der Klebstoff, der alles zusammenhält)

Beide Teile werden auf neue Weise hergestellt, die besser für unsere Welt ist.

Warum Sie unsere Hilfe brauchen

Die Herstellung guter Kohlefaser ist sehr schwer. Es braucht:

- Der richtige Fasermix

- Die richtige Harzart

- Die richtige Hitze (180°C/356°F)

- Der richtige Druck (6 bar/87 psi)

- Die richtige Zeit (4 Stunden)

- Die richtigen Leute, die wissen, wie alles geht

Die meisten Werkstätten sind nicht in der Lage, leichte und zugleich stabile Kohlefaserteile herzustellen. Ihnen fehlen die Werkzeuge. Ihnen fehlt das Know-how.

Schlechte Kohlefaserteile können:

- Machen Sie Pausen, wenn Sie sie am meisten brauchen

- Kostet Sie auf lange Sicht mehr

- Menschen in Gefahr bringen

- Sieht nach kurzer Zeit schlecht aus

Warum unser Unternehmen Ihre beste Wahl ist

Wir haben Top-Carbonfaserteile für 28+ JahreWir wissen, wie man das Beste macht benutzerdefinierte Kohlefaser Teile für Sie.

Unser Team kann Ihnen bei Folgendem helfen:

- Benutzerdefinierte Formen – Wir fertigen jedes Teil, das Sie sich vorstellen können

- Geringes Gewicht – Unsere Teile sind so leicht wie möglich

- Starke Teile – Unsere Teile gehen nicht kaputt, wenn Sie sie brauchen

- Tolles Aussehen – Unsere Kohlefaser sieht erstklassig aus

- Pünktliche Arbeit – Wir liefern Ihnen Ihre Teile zum vereinbarten Zeitpunkt

Wie wir kundenspezifische Kohlefaserteile herstellen

Wir verwenden dieselben Schritte wie die Top-Rennteams:

- Wir beginnen mit oben Prepreg-Technologie – formfertige Carbonfaser

- Für optimale Festigkeit verlegen wir jede Schicht von Hand

- Wir verwenden große Autoklaven (Spezialöfen) zum Aushärten der Teile

- Wir prüfen jedes Teil auf seine Perfektion

- Wir vollenden jedes Teil, sodass es großartig aussieht

Auf die gleiche Weise stellen Rennteams und Top-Autohersteller wie McLaren ihre Teile her.

Carbonfaser für alle Einsatzzwecke

Wir fertigen nicht nur Teile für Rennwagen. Wir produzieren Kohlefaser für:

- Motorräder aus Kohlefaser – Tanks, Kotflügel und mehr

- Sportwagen – Bodykits, Motorhauben und Kotflügel

- Boote – leicht und rostfrei

- Fahrräder – Rahmen, die leicht und steif sind

- Medizinische Werkzeuge – leichte Werkzeuge, die nicht kaputt gehen

- Drohnen - Rahmen die leicht und stark sind

Unser maßgeschneiderter Carbonfaser-Service

Wenn Sie mit uns arbeiten, erhalten Sie:

- Kostenlose Hilfe mit Ihrem Design

- Kostenloses Angebot damit Sie die Kosten im Voraus kennen

- Testteile um sicherzustellen, dass sie richtig passen

- Top-Finish auf allen Teilen

- Pünktlicher Versand um Ihnen schnell Teile zukommen zu lassen

Echte Geschichten unserer Kunden

„Wir haben drei andere Carbonfaser-Shops ausprobiert, bevor wir Sie gefunden haben. Ihre Teile passen auf Anhieb und sehen super aus!“ – Rennteamchef

„Meine Carbon-Motorhaube ist auf jeder Automesse ein Blickfang. Die Webart ist perfekt und der Klarlack glänzt auch nach zwei Jahren noch.“ – Gewinner der Automesse

„Unsere medizinischen Instrumente müssen leicht, aber robust sein. Ihre Carbonfasergriffe sind die besten, die wir gefunden haben.“ – Hersteller medizinischer Instrumente

Schritte zum Erhalt Ihrer individuellen Kohlefaserteile

So einfach arbeiten Sie mit uns:

- Senden Sie uns Ihre Idee – eine Zeichnung, ein Teil oder sagen Sie uns einfach

- Erhalten Sie ein schnelles Angebot – wir nennen Ihnen Kosten und Zeit

- Wir fertigen ein Testteil – um sicherzustellen, dass es richtig ist

- Wir fertigen Ihre Teile – immer pünktlich

- Wir versenden an Sie – schnell und sicher

Warum warten? Holen Sie sich jetzt bessere Teile

Geben Sie sich nicht mit schweren Teilen zufrieden, die kaputtgehen. Warten Sie nicht auf Geschäfte, die ihre Termine nicht einhalten.

Holen Sie sich das Beste Kohlefaserteile vom Team mit 28+ Jahre an Know-how.

Kontaktieren Sie uns noch heute um mit der Erstellung Ihrer individuellen Kohlefaserteile zu beginnen!

Wie wir Carbonfasern verbessern

Wie die Rennteams liegt uns die Umwelt am Herzen. Wir arbeiten an:

- Geringerer Energieverbrauch bei der Herstellung von Teilen

- Wege finden, alte Kohlefasern wiederzuverwenden

- Herstellung langlebigerer Teile

- Verwendung neuer Harze, die besser für unsere Umwelt sind

Die Zukunft der Kohlefaser

Kohlefaser wird immer besser. Neue Herstellungsverfahren werden:

- Senken Sie die Kosten um 25%

- Machen Sie es einfacher zu beheben

- Erleichtern Sie die Wiederverwendung alter Teile

- Sorgen Sie für weniger schlechte Luft, wenn wir sie erzeugen

Mercedes plant, bis 2040 Netto-Null-Kohlefaser zu verwenden. Auch wir haben vor, dieses Ziel zu erreichen.

Bereit für Ihre Kohlefaserteile?

Mit 28+ Jahre Bei der Herstellung von Kohlefaserteilen wissen wir, wie wir die besten Teile für Sie herstellen können.

Warten Sie nicht. Geben Sie sich nicht mit weniger zufrieden.

Kontaktieren Sie unser Team noch heute um mit der Herstellung Ihrer individuellen Kohlefaserteile zu beginnen!