BMW S1000RR Carbonfaser-Bauchspoiler: Der ultimative Upgrade-Leitfaden

Tust du hassen Wie sieht Ihre BMW S1000RR aus? Die serienmäßiger Kunststoff-Unterbodenschutz Ist schwer. Es bricht leichtEs sieht langweilig.

Viele Fahrer sind damit konfrontiert großes Problem. Ihr Fahrrad sollte so gut aussehen, wie es fährt!

Denken Sie darüber nach:

- Ihr Fahrrad wiegt zu viel

- Der Wind treibt Ihr Fahrrad mit hoher Geschwindigkeit herum

- Andere Fahrer haben coolere Fahrräder

- Kunststoffteile reißen und brechen bei Stößen

Das macht das Fahren weniger Spaß! Sie haben viel Geld für Ihren BMW ausgegeben. Er soll das Beste sein, was er sein kann!

Warum Ihr Fahrrad jetzt einen Carbonfaser-Unterbodenschutz braucht

Je mehr Sie damit fahren serienmäßiger Kunststoff-Unterbodenschutz, desto mehr Probleme bemerken Sie:

- Hitzeschäden – Kunststoff verzieht sich mit der Zeit

- Straßenschmutz schlägt und knackt es

- Alle anderen hat das gleiche langweilige Aussehen

- Ihr Fahrrad ist schwerer als nötig

Schauen Sie sich dieses Diagramm an, das zeigt, echte Probleme mit serienmäßigen Bugspoilern:

| Problem | Kunststoff | Kohlefaser |

|---|

| Gewicht | Schwer (2,7 kg) | Licht (1,5 kg) |

| Suchen | Langweiliger Fabriklook | Vom Rennsport inspirierter Stil |

| Stärke | Knackt beim Schlagen | 5x stärker |

| Hitzebeständigkeit | Verzieht sich bei hohen Temperaturen | Belastbar bis 400 °C |

| Windwiderstand | Grundform | 12% weniger Luftwiderstand |

Die perfekte Carbonfaserlösung für Ihren BMW

Gute Neuigkeiten! Wir machen Brauch Kohlefaser-Bauchwannen die ALLE diese Probleme beheben!

Unser BMW S1000RR Carbonfaser-Bauchspoiler verwendet spezielle Hightech-Kohlefaser das macht dein Bike aus:

- Sieht toll aus mit rennsportinspiriertem Stil

- Fühlen Sie sich leichter mit 1,2kg Gewichtsersparnis

- Bleiben Sie stabil mit besserem Luftstrom

- Länger haltbar mit stärkeren Materialien

Wir fertigen nicht nur Teile. Wir fertigen Leistungssteigerungen die Ihr Fahrrad verwandeln!

Warum unsere Carbonfaser-Bauchwannen alle anderen übertreffen

Nicht jede Kohlefaser ist gleich! Sehen Sie, was unsere Bugspoiler zu den beste Wahl:

Materialien, die Rennen gewinnen

Wir verwenden ausschließlich TORAYCA® PREPREG Kohlefaser aus Japan – das gleiche Material, das verwendet wird in:

- Formel-1-Rennwagen

- MotoGP-Motorräder

- Kampfjets

Dies ist keine billige Kohlefaser! Dies ist echtes Rennmaterial!

Jedes Mal perfekte Passform

Unsere Bugspoiler passen perfekt auf Ihrer BMW S1000RR, weil:

- Wir verwenden 3D-Scannen Ihres genauen Fahrradmodells

- Wir testen die Passform jedes Designs vor der Produktion

- Wir stellen sicher, dass alle Abgassysteme mit unseren Pfannen funktionieren

Keine Teile mehr, die „fast passen“ – unsere passen perfekt jedes Mal!

Besser gebaut als Fabrikteile

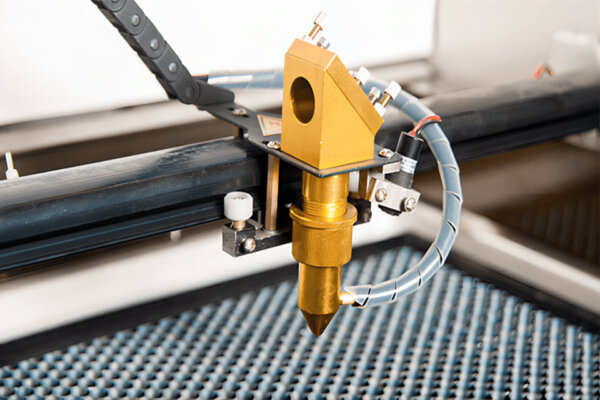

Schauen Sie, wie wir jeden BMW Carbonfaser-Bauchschutz:

- Schneiden Sie perfekte Carbonfaserplatten

- In spezielle Formen geben

- Auf 400 °C (752 °F) erhitzen

- Mit 5kg/cm² Druck pressen

- UV-Schutzbeschichtung hinzufügen

- Polieren für ein perfektes Finish

- Testen Sie die Passform an echten Fahrrädern

- In speziellen Schaumstoffboxen verpacken

Deshalb halten unsere Bauchpanzer länger und passen besser!

Benutzerdefinierte Optionen, die sonst niemand anbietet

Wir wissen, dass Fahrer wollen Auswahlmöglichkeiten! Deshalb bieten wir:

Zur Auswahl stehende Ausführungen:

- Glänzend Glanz, der nass aussieht

- Matt Finish für Stealth-Look

- Geschmiedet Textur für einzigartigen Stil

Webmuster:

Kompatibilitätsoptionen:

- Straßenversion (funktioniert mit Serienauspuff)

- Rennversion (versiegelter Boden für die Rennstrecke)

- Maßgefertigte Ausschnitte für spezielle Auspuffanlagen

Sehen Sie, was echte Fahrer über unsere Carbonfaser sagen

Verlassen Sie sich nicht nur auf unser Wort – hier ist, was echte BMW S1000RR-Besitzer sagen:

„Ich habe diesen Unterbodenschutz vor einem Renntag montiert. Mein Motorrad sah auf den Fotos nicht nur besser aus, ich konnte auch den Unterschied in der Stabilität bei hohen Geschwindigkeiten spüren!“ – Mike T.

„Die Installation dauerte nur 30 Minuten. Die Passform passte perfekt zu meiner Akrapovic-Auspuffanlage. Jetzt fragt mich jeder nach meinem Motorrad, wenn ich es abstelle!“ – Sarah K.

„Ich bin mit diesem Unterbodenschutz zweimal gestürzt. Er hat meinen Motor beide Male gerettet und sieht immer noch super aus!“ – Tom R.

So wählen Sie die richtige Carbonfaser-Bauchwanne

Wie fällt Ihnen bei so vielen Optionen die richtige Wahl? Hier ist eine einfache Anleitung:

Für Straßenfahrer:

Holen Sie sich unsere Straßenversion das mit Ihrem Serienauspuff funktioniert. Das bietet Ihnen:

- Einfache Installation (30 Minuten)

- Kein Austausch anderer Teile erforderlich

- Perfekte Passform ohne Modifikationen

Für Track Day-Helden:

Wählen Sie unser Rennversion mit:

- Vollständig versiegeltes Bodendesign

- Maximaler aerodynamischer Nutzen

- Zusätzlicher Schutz für den Einsatz auf der Rennstrecke

Für Showbikes:

Unser Benutzerdefiniertes Finish Die Option bietet Ihnen:

- Einzigartige Webmuster

- Spezielle Farboptionen

- Passende Teile erhältlich

Vollständiger Vergleich: Unsere Bauchpfannen vs. Andere

| Besonderheit | Unser Kohlefaser | Andere Marken | Serienmäßiger BMW |

|---|

| Gewicht | 1,5 kg | 1,7-2,3 kg | 2,7 kg |

| Material | TORAYCA® PREPREG | Verschiedene Qualitäten | Plastik |

| Wärmeprozess | 400°C Autoklav | Variiert je nach Marke | Spritzguss |

| Druckhärtung | 5kg/cm² | Niedriger oder keine | Keiner |

| Ausführungen | 3 Typen | Beschränkt | Keiner |

| Weboptionen | 4 Muster | Beschränkt | Keiner |

| Garantie | 2 Jahre weltweit | 1 Jahr typisch | 1 Jahr |

| Preis | $750-950 | $635-1,400 | $320 (OEM) |

| Ausstattung | Perfekte Passform-Garantie | Möglicherweise ist eine Anpassung erforderlich | Fabrikanpassung |

So erhalten Sie Ihren perfekten Carbonfaser-Bauchspoiler

Der Kauf Ihres neuen Bugspoilers ist einfach:

- Wählen Ihr Modelljahr (2019-2025)

- Wählen Ihr Finish (glänzend/matt/geschmiedet)

- Wählen Ihr Muster (12K/3K/Kevlar)

- Befehl mit kostenlosem weltweiten Versand

- Erhalten in spezieller Schutzverpackung

- Installieren mit einfachen Werkzeugen (30 Minuten)

- Genießen Ihr aufgewerteter BMW!

Warum wir die besten Carbonfaserteile herstellen

Wir sind nicht nur Verkäufer. Wir sind Carbonfaser-Experten. Unsere Fabrik verfügt über:

- 28 Jahre Erfahrung in der Herstellung von Kohlefaserteilen

- Ingenieure, die Motorradrennen fahren

- Prüflabor zur Qualitätskontrolle

- 3D-Scantechnologie

- Autoklavendrucksysteme

- UV-Prüfkammern

Wenn Sie bei uns kaufen, erhalten Sie Teile von Menschen, die liebe Motorräder genau wie du!

Mehr als nur Bugspoiler: Vervollständigen Sie Ihren Carbon-Look

Möchten Sie Ihre BMW S1000RR noch besser machen? Entdecken Sie unsere anderen Motorrad aus Kohlefaser Teile:

- Vordere Kotflügel

- Tankabdeckungen

- Kettenschutz

- Seitenwände

- Armaturenbrettabdeckungen

- Schwingenabdeckungen

- Hinterradkotflügel

Holen Sie sich ein passendes Set für den kompletten Race-Look!

Warten Sie nicht – führen Sie noch heute ein Upgrade durch!

Ihr BMW hat etwas Besseres verdient als schwere, hässliche Plastikteile. Unser Kohlefaser-Bauchwannen:

- Machen Sie Ihr Fahrrad besser aussehen

- Machen Sie Ihr Fahrrad sich leichter fühlen

- Machen Sie Ihr Fahrrad stabiler

- Machen Sie Ihr Fahrrad auffallen

Schließen Sie sich Tausenden zufriedenen BMW-Fahrern an, die auf unsere benutzerdefinierte Kohlefaser Teile!

Jetzt bestellen und verwandeln Sie Ihre BMW S1000RR noch heute!

FAQ: Häufige Fragen zu Carbonfaser-Bauchwannen

Passt das zu meinem BMW-Modelljahr?

Ja! Wir fertigen Bugspoiler für alle BMW S1000RR Baujahre 2009–2025. Wählen Sie bei der Bestellung einfach Ihr Modelljahr aus.

Nein! Sie benötigen lediglich einfaches Werkzeug. Die Installation dauert etwa 30 Minuten.

Funktioniert das mit meinem Aftermarket-Auspuff?

Ja! Unsere Bugspoiler sind mit Serien- und den meisten Aftermarket-Auspuffanlagen kompatibel. Wenn Sie ein spezielles System haben, kontaktieren Sie uns für individuelle Optionen.

Wie viel Gewicht spare ich?

Sie sparen etwa 1,2 kg (2,6 Pfund) im Vergleich zur serienmäßigen Kunststoff-Unterbodenwanne.

Wie reinige ich Kohlefaser?

Verwenden Sie einfach Wasser und Seife! Tragen Sie anschließend Autowachs auf, damit es wie neu aussieht.