Suchen Sie nach mehr Leistung Und Geschwindigkeit in Ihrem Auto? Unser benutzerdefinierte Kohlefaser Antriebswellen sind die Antwort! Wir machen sie in unserem Top Produktionsanlagen für Kohlefaserprodukte. Unsere Antriebswellen helfen Autos, Flugzeugen, Booten und Rennteams, schneller zu fahren und besser zu funktionieren.

Wir bedienen viele Arten von Kunden:

- Kraftfahrzeuge und Motorräder Hersteller

- Luft- und Raumfahrt Unternehmen

- Sportausrüstung Hersteller

- Medizinische Ausrüstung Hersteller

- Gebäude-Dekoration Firmen

- Unterhaltungselektronik Marken

- Schiffbau Unternehmen

- Industrielle Ausrüstung Hersteller

Unsere Kohlefaser-Antriebswellen sind Feuerzeug, stärker, Und besser als normale. Sie helfen Ihrem Auto oder Ihrer Maschine, optimal zu funktionieren.

Warum Carbonfaser-Antriebswellen Ihr Auto schneller machen

A Karbonfaser-Antriebswelle ist ein großer Gewinn für Ihr Auto. Es macht Ihr Auto schneller und verbraucht weniger Benzin. Die Welle wird aus speziellen Kohlefaserfilamente die sehr stabil sind. Unsere Antriebswellen sind bis zu 70% leichter als Metallwellen. Das bedeutet:

- Ihr Auto fährt schneller

- Sie verbrauchen weniger Benzin

- Ihr Auto fährt sich geschmeidiger

"Ich habe eine maßgeschneiderte Karbonfaser-Antriebswelle in meine Mustangund jetzt fühlt es sich an wie ein ganz neues Auto! Die Beschleunigung ist viel besser." - Tom R., Rennwagenfahrer

Der Drehmoment die Sie an Ihre Räder schicken können, ist mit unseren Antriebswellen viel höher. Sie können mehr Leistung aufnehmen, ohne zu brechen. Das ist der Grund, warum viele Autorennfahrer unsere Teile auswählen.

| Besonderheit | Stahl-Antriebswelle | Kohlefaser-Antriebswelle |

|---|

| Gewicht | 15-20 Pfund | 4-8 Pfund |

| Drehmomentkapazität | Gut | Exzellent |

| Kritische Geschwindigkeit | Untere | Höher |

| Vibration | Mehr | Weniger |

| Lebensdauer | 5-7 Jahre | 10+ Jahre |

Unsere Teile passen in viele Fahrzeuge wie BMW, GT, Und GT350 Modelle. Wir können die richtige Größe für Ihr Übertragung Und Achse.

Kundenspezifische Carbonfaser-Antriebswellen für jeden Bedarf

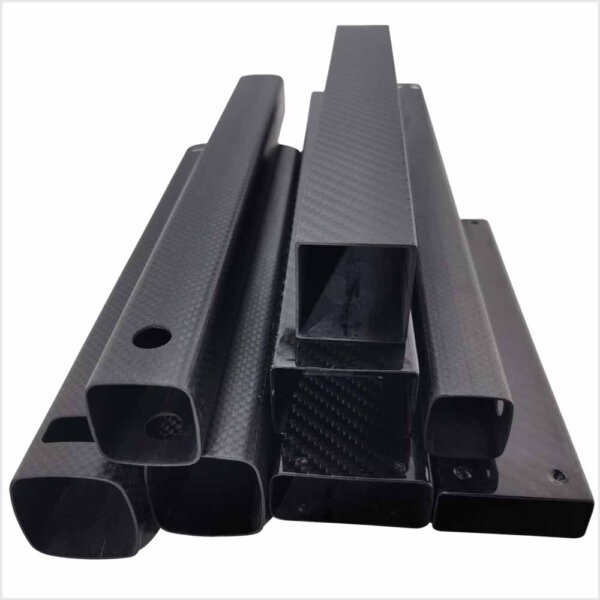

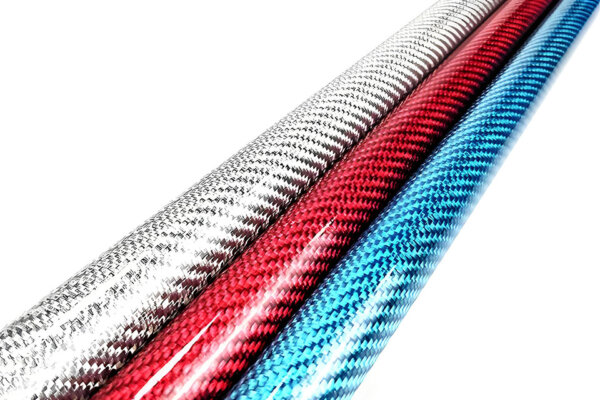

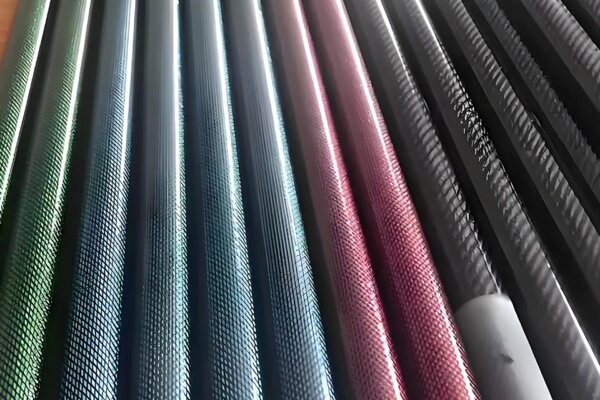

Wir machen jeden Antriebswelle nur für Sie. Unser Ingenieure prüfen Sie, was Sie brauchen und bauen Sie es richtig. Jeder ist Wunde im Haus mit unserem speziellen Harz mischen. Sie können wählen aus:

- Serie 1350 Joche

- 1350 U-Gelenke

- Schlupfpasse Optionen

- CV Gelenke für AWD Autos

- Flansch Halterungen für den Rennsport

Alle unsere Teile sind SFI-zertifiziert für den Rennsport. Das heißt, sie sind auch bei hohen Geschwindigkeiten sicher. Sollte jemals etwas schiefgehen, sind unsere Antriebswellen nicht zerschlagen wie die aus Metall.

"Als ich mein Haus gebaut habe S197 Mustang für Drag Racing, wusste ich, dass ich etwas Besonderes für die Antriebsstrang. Dein Kundenspezifische Antriebswellen aus Kohlefaser gab mir den nötigen Vorsprung, um zu gewinnen." - Mike T., Profi Rennfahrer

Unser Bilanz Tests stellen sicher, dass jede Welle perfekt läuft. Kein Schütteln oder Rauschen wie bei Aluminium-Antriebswellen.

| Auto Typ | Beste Option für die Antriebswelle |

|---|

| Straßenautos | Standard-Kohlefaser |

| Schienenfahrzeuge | Leistungsstarke Serie |

| Drag Race Autos | Ultra-Serie mit 1480 |

| AWD Systeme | CV-Gelenk Carbonfaser |

| Mustang/GT | Maßgeschneiderte Kohlefaser |

Wie unser Carbonfaser-Herstellungsprozess funktioniert

Unser proprietär Prozess macht die besten Antriebswellen. Wir beginnen mit Top Kohlefaser und fügen unsere spezielle Mischung hinzu. Dann wir:

- Wickeln Sie die Fasern in präzisen Mustern für maximale Steifheit

- Wenden Sie unser spezielles Harz mischen

- Aushärtung unter perfekten Bedingungen

- Hinzufügen Joch Und U-Gelenk Teile

- Bilanz die gesamte Einheit

- Test für Drehmomentkapazität

- QA1 Qualitätskontrolle

Der Anleihe zwischen der Kohlefaser und den Metallteilen ist superstark. Wir verwenden einen Spezialkleber, der sich nicht löst. Das ist besser als Stahl oder Aluminium Teile, die brechen oder sich verbiegen können.

Torsionssteifigkeit ist bei unseren Antriebswellen viel höher. Das bedeutet, dass mehr von Ihrem Auto Pferdestärken zu den Rädern gelangt. Ihr Antriebsstrang funktioniert besser, und Ihr Fahrgestell fühlt sich fester an.

"Nach dem Wechsel von einem Aluminium-Antriebswelle zu Ihrem Kohlefaser eine, meine Viertelmeilenzeit ist um 0,3 Sekunden gesunken. Das ist im Rennsport enorm!" - Sarah K., Drag Racer

QA1 Antriebswelle Normen sind für uns nur der Anfang. Wir gehen darüber hinaus, um sicherzustellen, dass jedes Teil perfekt ist.

| Material | Gewichtsreduktion | Torsion Stärke | Kritische Geschwindigkeit |

|---|

| Stahl | 0% | Basis | Basis |

| Aluminium | 40% | 15% weniger | 20% höher |

| Kohlefaser | 70% | 40% weiter | 60% höher |

| Unser CF | 75% | 60% weiter | 75% höher |

Bestellen Sie Ihre individuelle Carbonfaser-Antriebswelle noch heute

Bereit, die Kraft der Antriebswellen aus Kohlefaser? Unser Team ist bereit, Ihnen zu helfen, das richtige Teil für Ihr Auto oder Projekt zu finden. Wir arbeiten mit:

- Autohäuser

- Rennteams

- Aftermarket Teilehersteller

- Automobilindustrie Fabriken

- Bastler

Das Verfahren ist einfach:

- Sagen Sie uns, welches Auto Sie haben

- Wählen Sie Ihre Joch Typ und U-Gelenke

- Wählen Sie beliebige Zusatzfunktionen

- Wir bauen Ihr kundenspezifisches Kohlefaserteil

- Wir liefern es Ihnen fertig zum Schraube In

Alle unsere Antriebswellen sind leichter und stärker als das, was in Ihrem Auto eingebaut war. Sie werden auch länger halten. Die Haltbarkeit ist erstaunlich. Sie können über unsere Website bestellen oder uns anrufen. Unsere Kohlenstofffabrik hat Experten, die Ihnen helfen können. Wir machen auch benutzerdefinierter Verbundstoff Teile für viele Verwendungszwecke.

Prüfen Sie unsere Arbeit für Autos aus Kohlefaser Und Kohlefaser-Motorräder um zu sehen, was wir tun können. Unser kundenspezifische Kohlenstofffasern Seite zeigt noch mehr Optionen.

Vorteile der Wahl unserer Carbonfaser-Antriebswellen

- Größeres Drehmoment Handhabung

- Geringeres Gewicht für besseren Benzinverbrauch

- Weniger Belastung für andere Fahrzeugteile

- Glatt Betrieb auch bei hohen Geschwindigkeiten

- Sieht toll aus in Ihrem Auto

- SFI-Sicherheit für den Rennsport

- Maßgeschneidert für Ihr spezielles Auto

- Höhere kritische Geschwindigkeit als Metallschäfte

Warten Sie nicht mit der Aufrüstung Ihres Fahrzeugs oder Projekts. Unser Antriebswellen aus Kohlefaser wird einen großen Unterschied machen, den Sie sofort spüren können.

Kontaktieren Sie uns unter [email protected]

Telefon/Whatsapp: + 86 136 2619 1009

Zusammenfassung: Unsere maßgefertigten Kohlefaser-Antriebswellen liefern unglaubliche Leistung mit 70% weniger Gewicht als Stahl, höherer Drehmomentkapazität und reibungsloserem Betrieb. Erleben Sie eine schnellere Beschleunigung, einen geringeren Kraftstoffverbrauch und eine längere Lebensdauer - und das alles bei perfekter Passgenauigkeit für Ihr spezielles Fahrzeug.