Notre usine de composites de carbone

As a trusted carbon factory, we provide advanced carbon fiber composites that combine strength, lightweight performance, and durability. Since 1998, we have invested in state-of-the-art technology and built production facilities in Suzhou, Zhenjiang, and Jinjiang, covering more than 80,000 square meters and supported by 120+ R&D specialists.

Our carbon fiber products serve a wide range of industries, including automotive, motorcycle, rail transit, sports and recreation, construction reinforcement, medical devices, consumer electronics, industrial equipment, renewable energy, and wind turbine blades. By integrating innovative design with strict quality control, our carbon factory continues to deliver reliable solutions that help global partners improve performance and efficiency.

Nos avantages

Our carbon factory combines advanced equipment with strong R&D to deliver high-performance carbon fiber components. We use servo-controlled hot-press molding machines with multi-stage pressure settings to ensure forming precision and high yield. High-accuracy mold processing allows complex designs, while tensile and compression testers validate strength and modulus.

On the R&D side, we apply precise PID-controlled thermal systems (±3°C), surface treatment, and microstructure analysis to enhance corrosion resistance and thermal stability. By partnering with universities and research institutes, our carbon factory drives continuous material innovation, offering reliable, lightweight, and durable solutions for global industries.

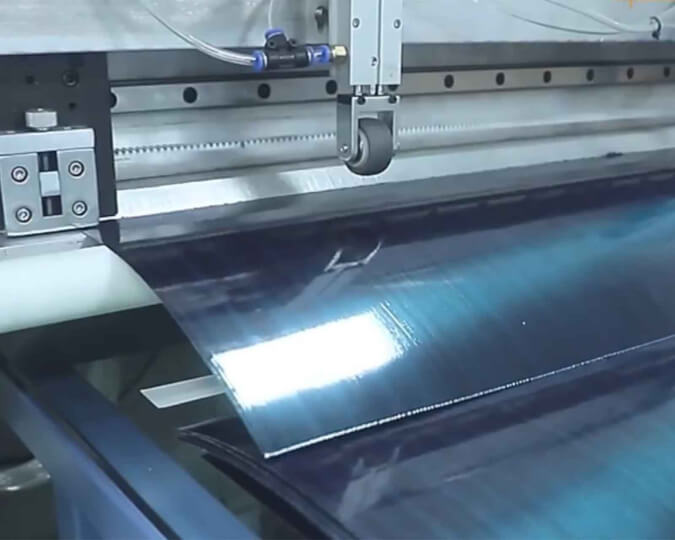

Our Composite Manufacturing

Our carbon factory delivers lightweight, high-strength solutions through advanced composite manufacturing. With automated production lines and high-precision molding technologies, we ensure consistent quality and efficiency at every stage. From autoclave processing to vacuum-assisted forming, our methods create durable components that outperform traditional materials.

Equipped for large-scale production, we supply carbon fiber sheets, profiles, and complex assemblies to aerospace, automotive, construction, and industrial markets. Combining automation, precision, and scalability, our carbon factory provides reliable, high-performance composites that help customers achieve lighter, stronger, and more efficient designs.

Notre mission

We pioneer the use of carbon composite technology to deliver groundbreaking material innovations, ranging from advanced graphite blends to durable carbon fiber plates.

Our goal is to provide sustainable composite solutions that meet the demands of diverse industries, including Aerospace & Aviation, Automotive & Motorsports, Wind Energy, Marine & Shipbuilding, Sporting Goods & Recreation, Civil Engineering & Construction, Industrial Manufacturing, Consumer Electronics, Medical & Healthcare, Oil & Gas, and Defense & Military. By focusing on practical applications and performance-driven design, we empower our clients with lightweight strength, superior durability, and even waterproof options tailored to their needs.

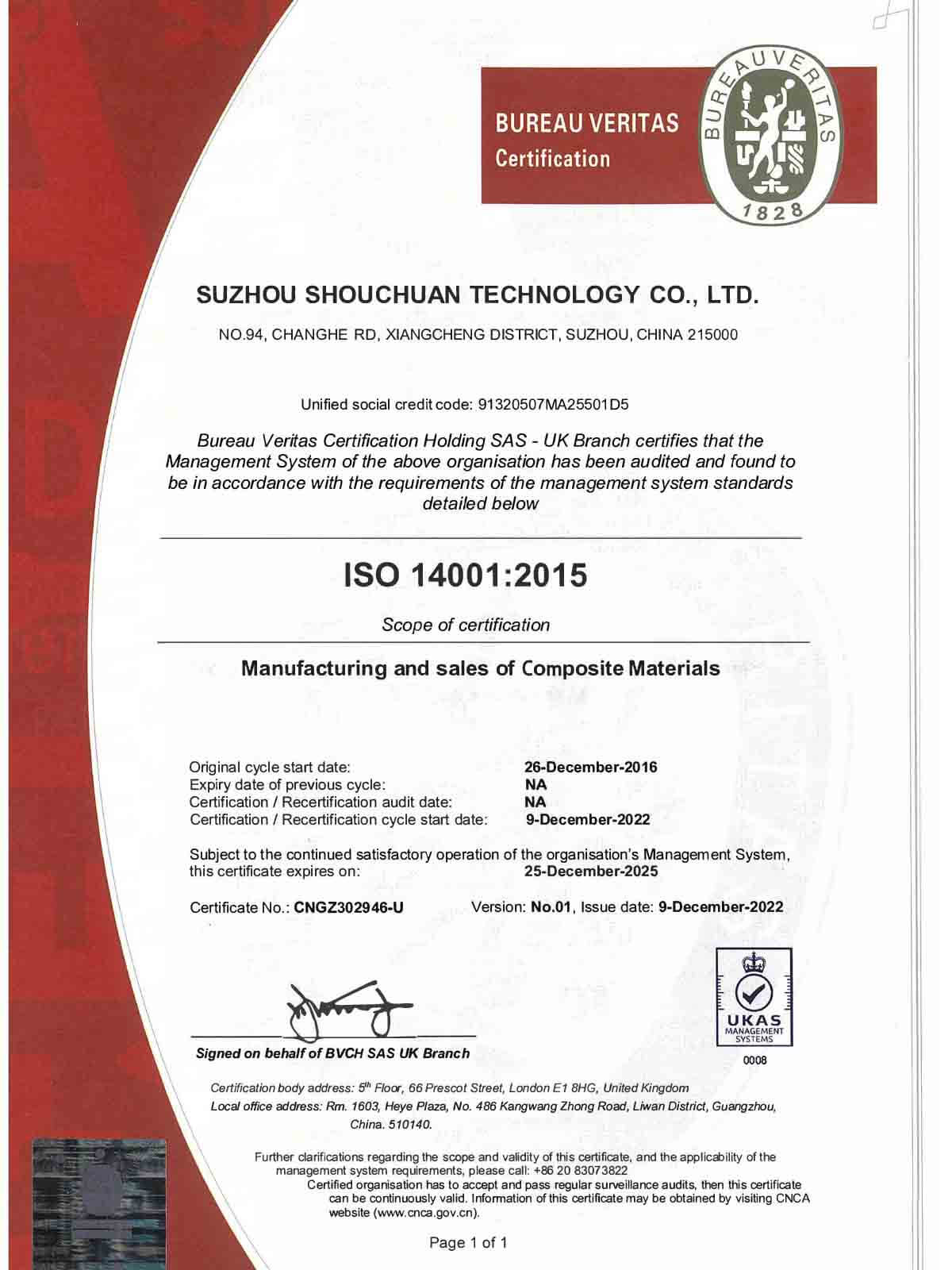

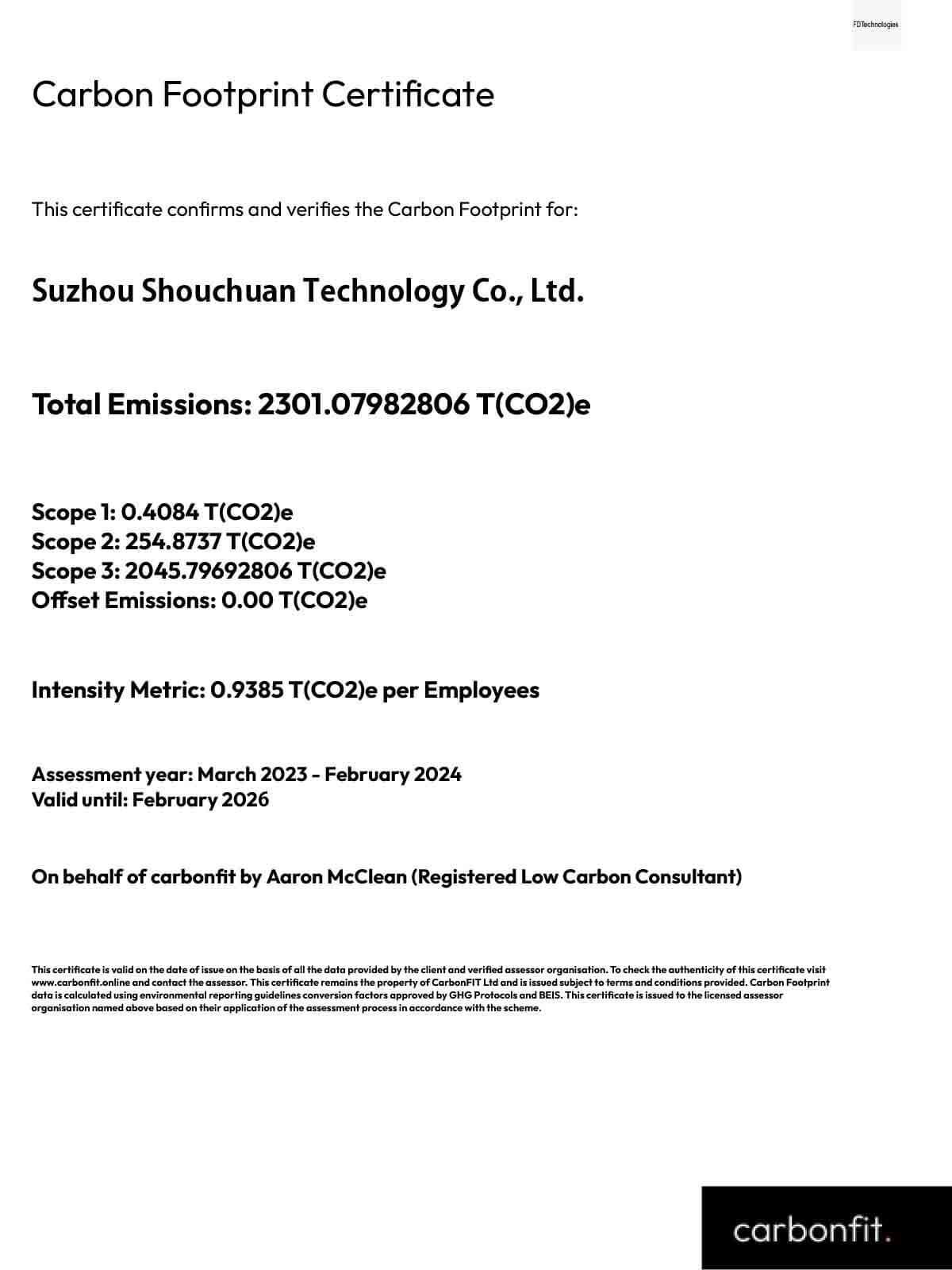

Nos certificats

Questions fréquemment posées

Yes. We specialize in customized carbon fiber solutions to meet your specific project requirements. Our engineering team can adjust thickness, weave pattern, resin system, surface finish, and dimensions according to your application. Whether you need lightweight panels, high-strength tubes, or complex molded parts, we can design and manufacture to your exact specifications.

Absolutely. We support both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing). For OEM, we produce according to your drawings, samples, or specifications. For ODM, we can assist in concept development, design optimization, and full-scale production. Our R&D and engineering teams have extensive experience in automotive, aerospace, sporting goods, industrial equipment, and consumer products.

Delivery depends on the order type and volume:

Standard products (such as auto parts, motorcycle parts, sheets, plates, or tubes in stock): 5–10 working days.

Customized products: usually 3–6 weeks, depending on complexity and order size.

We always aim to provide a clear lead time at the quotation stage and offer expedited production if your project is time-sensitive.

Yes, we provide global shipping. We work with reliable logistics partners to ensure safe and timely delivery worldwide. Depending on your preference and urgency, we can arrange shipping via air freight, sea freight, express courier (DHL, FedEx, UPS, TNT), or customer-designated forwarders. We also provide all necessary export documentation to ensure smooth customs clearance.

Our carbon fiber composites are used across multiple industries, including automotive, aerospace, marine, sports & recreation, robotics, industrial machinery, renewable energy, and medical equipment. If your application requires lightweight strength, precision, and durability, carbon fiber is the ideal choice.

We follow strict ISO-certified quality management systems and employ advanced testing methods such as tensile strength, compression, impact resistance, and dimensional accuracy checks. Every product undergoes rigorous inspection before shipment. Certificates of conformity and material data sheets are available upon request.

Our MOQ depends on the product type. For standard sheets or tubes, small batch orders are welcome. For customized or OEM/ODM products, the MOQ may vary based on production complexity. Please contact us for details—we are flexible and support both small pilot runs and large-scale production.

You can send us your drawings, specifications, or application requirements via email or through our website’s inquiry form. Our sales engineers will provide a detailed quotation, including material options, lead time, shipping terms, and payment methods.