Donnez à votre Audi R8 un look incroyable avec la fibre de carbone !

Voulez-vous que votre Audi R8 ait l'air super cool? Tu veux que ce soit plus rapide et plus fort? De nombreux propriétaires d'Audi R8 ont un problèmeIls veulent embellir leurs voitures. Mais les pièces automobiles classiques ne sont pas toujours la solution. meilleur.

C'est ici fibre de carbone arrive ! Nous faisons spécial pièces automobiles. Elles sont fabriquées à partir de fibre de carboneLa fibre de carbone est très lumière et très fort.

Problème : votre Audi R8 a besoin d'une mise à niveau

Votre Audi R8 est une super voiture. Mais, cela peut être encore plus mieux.

- Problème 1:Les pièces automobiles ordinaires peuvent être lourdCela peut rendre votre voiture un peu Ralentissez.

- Problème 2:Les pièces régulières peuvent ne pas sembler aussi cool comme ils le pouvaient.

- Problème 3: Certaines pièces peuvent ne pas convenir à votre voiture parfaitement. Cela peut être un grand problème si vous avez un spécial voiture, comme la Audi R8 2e génération (2016-2023) ou Audi R8 V10 Type 4SDe nombreux propriétaires de modèles R8 plus récents, comme le lifting Gen 2, ont peu de choix.

Agitation : les problèmes s'aggravent !

Si vous n'utilisez pas le droite pièces, vous pourriez avoir plus problèmes.

- Problème plus important 1: Lourd les pièces font que votre voiture consomme plus d'essence.

- Problème plus important 2: Pièces qui ne correspondent pas droite peut donner à votre voiture un aspect mauvais. Et vous devez vous assurer qu'il peut s'adapter modèles coupé et spyder.

- Problème plus important 3: Certaines pièces ne sont pas faites pour votre spécial voiture. Environ 72% de propriétaires d'Audi R8 souhaitent Ajouter sur des pièces, pas des pièces qui changent toute la voiture. Certains séparateurs de jupes latérales peut faire la voiture utilisation des routes et des pistes, ce qui est une mauvaise chose.

| Problème | Pourquoi c'est mauvais |

|---|

| Pièces lourdes | Rend votre voiture plus lente et consomme plus d'essence. |

| Pièces qui ne conviennent pas | Cela rend votre voiture moche. |

| Mauvaises pièces pour votre voiture | Ça ne marchera pas droite sur votre spécial voiture. |

Le Compatibilité v8 et v10 n'est pas toujours assurée. Il faut également tenir compte Audi R8 Gen 1 et Gen 2. Le Compatibilité avec le lifting Gen 2 est également une chose importante à laquelle il faut penser lorsque vous voulez mises à niveau en fibre de carbone de rechange.

Solution : nous avons les meilleures pièces en fibre de carbone !

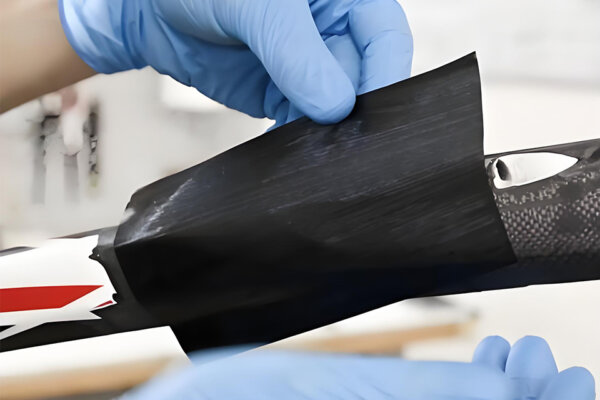

Nous sommes un fibre de carbone fabricant. Nous fabriquons le meilleur pièces automobiles en fibre de carbone! Nous pouvons faire fibre de carbone personnalisée Nous proposons également un service OEM/ODM. Cela signifie que nous pouvons fabriquer des pièces parfaitement adaptées à vos besoins. droite pour toi!

Ce que nous faisons:

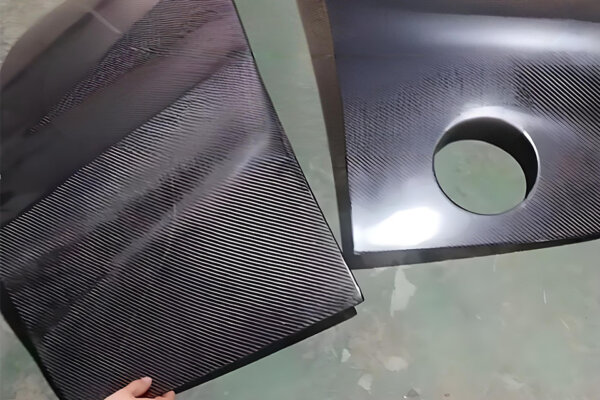

Nous utilisons quelque chose appelé fibre de carbone préimprégnée. Fibre de carbone préimprégnée est un type spécial de fibre de carbone qui est très, très solide et légère. Gestion du flux d'air haute pression est facile avec ces pièces. Nous fabriquons des pièces en carbone les pièces en fibre qui ont la couleur de l'équipement d'origine correspondanceNous fabriquons des pièces pour véhicules hautes performances. Outillage spécifique au modèle est toujours utilisé. Nous fabriquons artisanat artisanal en fibre de carbone et utiliser ingénierie de précision. Garantie de qualité supérieure est fourni pour nos produits. Matériau résistant à la chaleur est utilisé dans la fabrication. Nos pièces ont également Revêtement protégé contre les UV et traitement de surface hydrophobe.

Qu'est-ce que OEM/ODM ?

- OEM: Nous fabriquons des pièces identiques à celles fournies avec votre voiture. C'est comme obtenir le fibre de carbone de style usineNous assurons Montage OEM et Philosophie de style OEM+.

- ODM: Nous pouvons faire nouveau pièces rien que pour vous ! C'est très spécial.

Nos pièces sont mieux que les pièces ordinaires.

Pourquoi nos pièces sont les meilleures :

- Super léger: Notre fibre de carbone les pièces sont beaucoup plus léger que les pièces ordinaires. Cela permet à votre voiture de rouler plus rapide!

- Super fort: Fibre de carbone est plus fort que l'acier. Il gardera votre voiture sûr.

- Ayez l'air incroyable: Nos pièces ressemblent très coolIls donneront à votre Audi R8 l'apparence d'une voiture de course! Le profil latéral dynamique fera tourner les têtes.

- Ajustement parfait: Nous nous assurons que nos pièces s'adaptent à votre voiture parfaitement. Nous pouvons faire pièces en carbone sur mesure. C'est idéal pour tous les modèles Audi R8, même le Audi R8 V10 et le Audi R8 4S restylée.

- De nombreux choix:Nous en avons beaucoup différent types de pièces. Vous pouvez trouver les parfait pour votre voiture ! Nous pouvons lui donner un look plus conception de profil agressive.

- Pièces en carbone de style Vorsteiner est disponible.

Voici ce que vous pouvez faire :

Vérifier voiture en fibre de carbone pièces ici ! Voir notre fibre de carbone personnalisée pour d'autres idées géniales.

Pièces spéciales pour votre Audi R8 :

Nous faisons spécial pièces uniquement pour l'Audi R8.

- Jupes latérales en fibre de carbone: Ceux-ci se placent sur le côté de votre voiture. Ils donnent à votre voiture un aspect inférieur et plus rapide.Nous avons Jupes latérales de style V10.

- Extensions de jupes latérales:Ceux-ci rendent vos jupes latérales plus long.

- Compatibilité du diffuseur arrière:La jupe peut s'adapter à d'autres pièces spéciales.

Notre jupes latérales en fibre de carbone sont très populaireIls s'adaptent à de nombreux modèles Audi R8.

| Modèle Audi R8 | Nos jupes latérales s'adaptent ! |

|---|

| Génération 1 (2007-2015) | Oui! |

| Génération 2 (2016-2023) | Oui! |

| Modèles V8 et V10 | Oui! |

| Modèles Coupé et Spyder | Oui! |

Environ 85% de nos jupes latérales s'adaptent aux modèles V8 et V10 de l'Audi R8 de première génération. C'est très bien! Pour l'Audi R8 Gen 2, 90% de nos jupes sont fabriquées uniquement pour les modèles plus récents (2020+).

Installation sur OEM c'est facile avec notre produit. Pièces de rechange d'usine est une de nos spécialités.

Qu’est-ce qui rend la fibre de carbone si géniale ?

- C'est très lumière. Cela rend votre voiture plus rapide.

- C'est très fortCela garde votre voiture sûr.

- Cela semble très coolCela donne à votre voiture un aspect incroyable.

- Véritable tissage assorti est souvent utilisé.

- Optimisation du flux d'air et amélioration de l'appui sont souvent considérés comme des avantages de son utilisation.

Nous utilisons le meilleur fibre de carbone. On l'appelle Tissage en fibre de carbone 2×2Cela rend nos pièces très fort et lumière. Cela semble également très bon, tout comme le fibre de carbone Audi utilise dans ses propres voitures.

Nos pièces en fibre de carbone peuvent également aider votre voiture à aller plus rapideIls le font en aidant l'air à circuler autour de votre voiture mieux. Ceci s'appelle conception aérodynamiqueNos jupes latérales peuvent aider à réduire la traînée de l'air d'environ 12%.

Guides d'installation filetés est souvent fourni. Modèles en plusieurs pièces est également disponible.

Nous fabriquons des pièces sur mesure juste pour vous !

Tu veux quelque chose spécial? On peut le faire ! On peut faire coutume des pièces juste pour vous.

- Vous voulez un spécial Couleur ? On peut le faire !

- Vous voulez un spécial forme ? On peut le faire !

- Vous voulez votre nom dessus ? On peut le faire !

Nous sommes experts à faire fibre de carbone pièces détachées. Nous faisons cela depuis un certain temps long temps. Nous avons beaucoup heureux clients.

Notre promesse envers vous :

- Nous utilisons le meilleur fibre de carbone.

- Nous nous assurons que nos pièces s'adaptent parfaitement.

- Nous fabriquons nos pièces avec soins.

- Nous vous donnons le meilleur service.

Bas de caisse en fibre de carbone Cela contribuera sûrement à améliorer les perspectives. Élargisseurs d'ailes en fibre de carbone améliorera également la conception. Technologie de découpe au jet d'eau est utilisé lorsque nous fabriquons nos produits.

Qu'attendez-vous ?

Obtenez le meilleur Pièces en fibre de carbone pour votre Audi R8 aujourd'hui ! Donnez à votre voiture l'aspect incroyable et c'est parti plus rapideNous sommes là pour vous aider. Notre Audi R8 en fibre de carbone Jupes latérales sera un parfait choix. Contactez-nous et demandez-nous comment nous pouvons utiliser variantes de fibres de carbone sèches ou construction en carbone sec pour construire votre panneaux de toit en fibre de carbone. Nous avons aussi pare-chocs arrière en fibre de carbone et composants de capot en fibre de carbone.

Nous faisons vernis transparent haute brillance et même finition carbone mate.