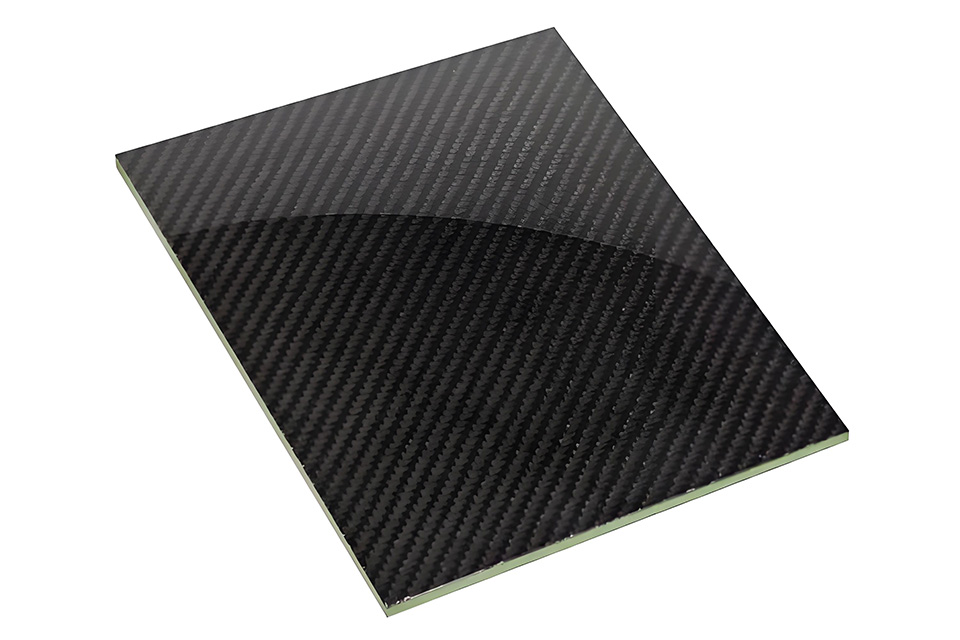

Procédé de moulage par pressage à chaud de matériaux composites en fibre de carbone

Notre usine utilise un processus avancé de presse à chaud en fibre de carbone avec un moule en acier P20, garantissant une efficacité, une précision, une durabilité et une rentabilité élevées pour une production de qualité.