De quelle couleur est la fibre de carbone ? Guide complet

Vous recherchez des pièces en fibre de carbone personnalisées mais vous ne savez pas quelles couleurs choisir ? Vous n'êtes pas seul. De nombreux passionnés de voitures et de motos nous posent cette question.

Le gros problème avec les couleurs de la fibre de carbone

Aspect fibre de carbone noir. Juste du noir. Le même noir à chaque fois.

C'est un gros problème Pour les marques et les automobilistes qui souhaitent se démarquer. Si toutes les pièces en fibre de carbone se ressemblent, comment votre produit peut-il être unique ?

Pensez-y :

- Ton voiture de luxe a les mêmes pièces en carbone noir que tout le monde

- Ton équipement sportif se fond dans la concurrence

- Ton produits personnalisés manque de cette touche spéciale

Cela rend les clients tristes. Cela nuit aux ventes. Cela empêche les marques d'être uniques.

Pourquoi ce problème de couleur s'aggrave

Le problème de la couleur s'aggrave. De plus en plus d'industries utilisent la fibre de carbone chaque jour.

D'ici 2025, le marché de la fibre de carbone vaudra $23,7 milliardsD'ici 2035, elle atteindra $44,7 milliards.

Mais la plupart des pièces sont toujours d’une seule couleur – noir ennuyeux.

Lorsque vous achetez des pièces en fibre de carbone, vous êtes confronté à :

- Options de conception limitées

- Même look que les concurrents

- Aucun moyen de faire correspondre les couleurs de votre marque

Cela nuit à votre marque. Vos produits se fondent dans la masse au lieu de se démarquer.

La solution couleur dont vous avez besoin

Bonnes nouvelles! Notre usine a résolu ce problème. Forts de plus de 28 ans d'expérience dans la fabrication de pièces en fibre de carbone, nous avons réalisé des avancées en matière de couleurs inégalées.

Nous offrons fibre de carbone colorée sur mesure qui garde toute la force tout en ajoutant de la beauté.

De quelles couleurs peut réellement être la fibre de carbone ?

Examinons les faits concernant les couleurs de la fibre de carbone :

| Type de couleur | À quoi ça ressemble | Idéal pour | Notre spécialité |

|---|---|---|---|

| Noir naturel | Noir profond avec tissage gris | Pièces solides, look classique | ✓ Motif de tissage parfait |

| Résine colorée | Fibre noire avec brillance colorée | Des touches de couleurs subtiles | ✓ 12 nuances personnalisées |

| Couleurs | Changement de couleur complet | Couleurs de marque assorties | ✓ Notre procédé spécial |

| Aspect carbone forgé | Motif marbré | Pièces détachées automobiles de luxe | ✓ Qualité Lamborghini |

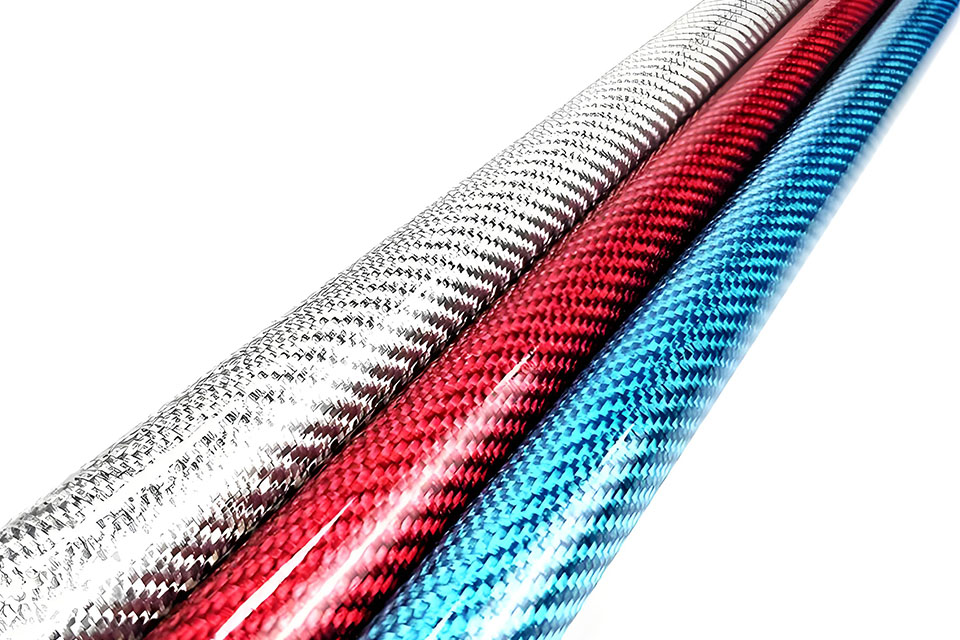

Nos couleurs les plus demandées en 2025 :

- Gris métal (38% de commandes)

- Bleu profond (22% de commandes)

- Noir classique (40% de commandes)

Pourquoi la fibre de carbone paraît-elle noire ?

La fibre de carbone est naturellement noir En raison de sa composition, les atomes de carbone absorbent toutes les ondes lumineuses, ce qui lui donne un aspect très sombre.

C'est bon pour la résistance mais mauvais pour le design.

La plupart des fabricants ne peuvent pas changer cette couleur sans :

- Rendre les pièces plus faibles

- Ajouter trop de poids

- Augmentation des coûts par 30%

Notre processus de couleur spécial

Après 28 ans de fabrication de pièces en fibre de carbone, nous avons trouvé une meilleure solution.

Notre procédé de coloration spécial garde:

- Résistance totale (1,65 GPa – identique à la fibre de carbone ordinaire)

- Léger (pas de peinture lourde)

- Couleur longue durée qui ne s'écaille pas

Comment nous colorons la fibre de carbone

Nous utilisons trois méthodes principales pour ajouter de la couleur :

- Résine teintée – La couche transparente prend de la couleur tandis que les fibres restent noires

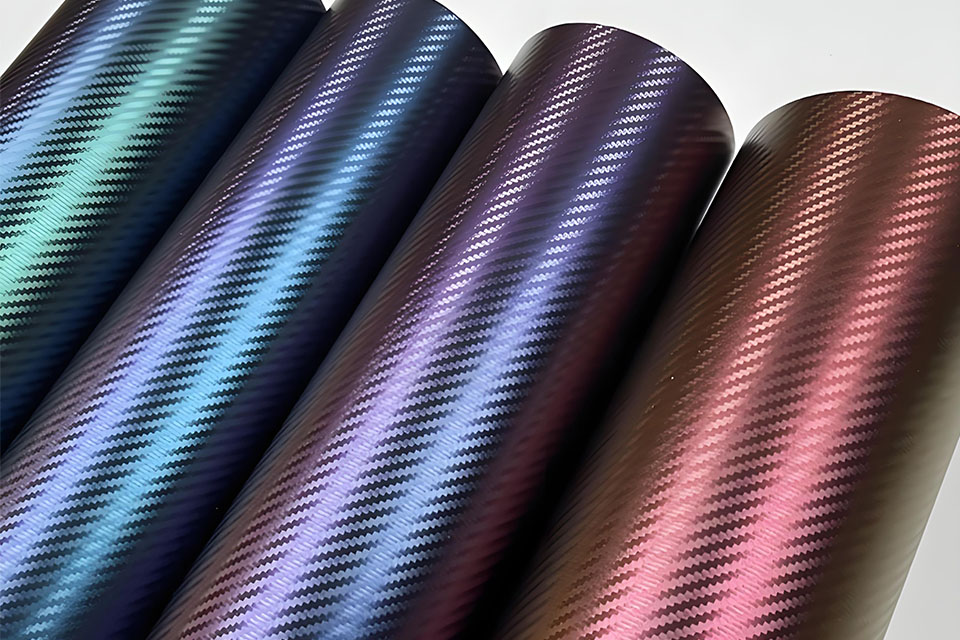

- Revêtement nano – Une couche de couleur ultra-fine se lie aux molécules de carbone

- Fibres mixtes – Fibres colorées tissées avec du carbone pour des looks uniques

Couleurs de fibre de carbone personnalisées pour différentes industries

Chaque entreprise a besoin de couleurs différentes. Voici ce que nous proposons :

Pour les constructeurs automobiles

Les constructeurs automobiles adorent notre fibre de carbone personnalisée pièces. En 2025, 42% en fibre de carbone colorée va aux voitures.

Nous faisons:

- Tableaux de bord aux couleurs assorties

- Spoilers en carbone forgé pour les marques de luxe

- Pièces de finition colorées qui correspondent exactement à la peinture

La plupart des acheteurs de voitures paieront 10% plus pour de la fibre de carbone colorée sur mesure à l'intérieur de leurs voitures.

Pour les pièces de moto

Pièces de moto en fibre de carbone il faut être fort ET élégant.

Nos options de couleur incluent :

- Couvercles de réservoir d'essence qui correspondent à la peinture de votre vélo

- Garde-boue avec des motifs personnalisés

- Boucliers d'échappement dans des couleurs résistantes à la chaleur

Pour les équipements sportifs

Les marques de sport veulent se démarquer. Nous les aidons à :

- Raquettes de tennis aux couleurs de l'équipe

- Cadres de vélo avec des effets de fondu de couleur

- Manches de clubs de golf avec une image de marque personnalisée

Les avantages de notre fibre de carbone colorée

Lorsque vous travaillez avec nous, vous obtenez :

- Plus de 28 ans de savoir-faire en matière de fabrication

- Services OEM/ODM complets de la conception à l'expédition

- Couleurs personnalisées qui correspondent exactement à votre marque

- Même force comme la fibre de carbone ordinaire

- Pas de poids supplémentaire contrairement aux pièces peintes

Comparaison des coûts : notre processus par rapport aux autres

| Méthode de couleur | Perte de force | Poids ajouté | Augmentation des coûts | Notre usine |

|---|---|---|---|---|

| Peindre sur du carbone | Aucun | 5-8% plus lourd | +15% | Non utilisé |

| Résine teintée | Aucun | Aucun | +10-15% | ✓ Oui |

| Revêtement nano | Aucun | Aucun | +12% | ✓ Oui |

| Fibres colorées | Léger (2-3%) | Aucun | +20-25% | ✓ Pour des projets spéciaux |

Comment nous travaillons avec vous

Notre processus OEM/ODM facilite l'obtention de fibres de carbone colorées sur mesure :

- Dites-nous vos besoins – Envoyez des échantillons de couleurs, des dessins ou des pièces

- Nous faisons des échantillons – Voir et tester avant la production complète

- Production complète – Fabriqué selon vos spécifications exactes

- Contrôles de qualité – Chaque pièce est vérifiée pour la correspondance des couleurs

- Expédition sécurisée – Livré à temps, à chaque fois

Étude de cas : Histoires de réussite

Marque de voitures de luxe

Un constructeur allemand de voitures de luxe avait besoin tableau de bord en fibre de carbone en 3 custom couleurs.

Le problème:Les autres fournisseurs ne pouvaient proposer que des pièces noires ou peintes qui semblaient fausses.

Notre solution:Nous avons créé des correspondances de couleurs exactes grâce à notre processus de nano-revêtement.

Le résultat:Les ventes du pack intérieur premium ont augmenté de 24%. Les clients ont apprécié son look unique.

Fabricant d'équipements sportifs

Une entreprise de raquettes de tennis souhaitait des cadres en fibre de carbone à couleur changeante.

Le problème:Ils avaient besoin de force et d'un look spécial que les concurrents ne pouvaient pas copier.

Notre solution:Fibres de couleur personnalisée qui changent de couleur sous différents angles.

Le résultat:Leur nouvelle gamme de raquettes a été épuisée en deux semaines. Les joueurs ont adoré leur look unique.

Questions fréquentes sur les couleurs de la fibre de carbone

Q : La fibre de carbone colorée sera-t-elle aussi résistante ? UN: Oui! Notre fibre de carbone colorée conserve toute sa résistance (1,65 GPa).

Q : Combien de couleurs pouvez-vous créer ? UN: N'importe quelle couleur ! Nous pouvons faire correspondre n'importe quel code de peinture, couleur Pantone ou échantillon que vous envoyez.

Q : La couleur va-t-elle se gratter ? UN: Non. Contrairement à la peinture, nos couleurs font partie de la matière.

Q : La fibre de carbone colorée est-elle plus chère ? R : Cela coûte environ 10-15% de plus que la fibre de carbone noire, mais beaucoup moins que la peinture de rechange.

Pourquoi choisir notre usine ?

- Plus de 28 ans de fabrication de fibre de carbone – Nous savons ce qui fonctionne

- Service OEM/ODM complet – De la conception à la livraison

- Correspondance des couleurs personnalisée – N’importe quelle nuance dont vous avez besoin

- Pièces à pleine résistance – Aucun compromis sur la qualité

- Livraison à temps – Respecter votre calendrier de production

L'avenir des couleurs de la fibre de carbone

L'avenir s'annonce prometteur pour les couleurs de la fibre de carbone. D'ici 2025 :

- Revêtement nano représentera 12% du marché, réduisant les coûts de 40%

- Colorants durables rendra le carbone coloré plus écologique

- Changement de couleur intelligent la fibre de carbone réagira à la chaleur ou à la lumière

Comme le voiture en fibre de carbone Le marché se développe et de plus en plus de marques voudront des couleurs personnalisées pour se démarquer.

Passez à l'étape suivante

Ne vous contentez pas d’une simple fibre de carbone noire alors que votre marque mérite mieux.

Contactez-nous aujourd'hui pour :

- Échantillons de couleurs gratuits

- Devis de projet personnalisé

- Consultation en conception

Avec nos 28 années d'expérience et notre technologie de couleur personnalisée, nous pouvons résoudre vos problèmes de couleur de fibre de carbone.

Visitez notre site Web principal pour voir plus d'exemples ou contacter directement notre équipe.