Impression 3D en fibre de carbone : l'avenir des pièces solides et légères

Le problème : l'impression 3D normale est trop faible

Fabriquez-vous des choses avec une imprimante 3D ? Les pièces en plastique normales se cassent trop facilementIls se plient. Ils se cassent. Ils tombent en panne quand on en a le plus besoin.

C'est très mauvais lorsque vous avez besoin de pièces solides pour :

- Voitures

- Drones

- Outils

- Pièces de machines

Le plastique normal ne suffit pas. Il est trop fragile. Cela rend les gens très contrarié lorsque leurs pièces tombent en panne.

Pourquoi cela nuit à votre entreprise

Lorsque des pièces se cassent :

- Vous gaspillez de l'argent

- Les clients se mettent en colère

- Les projets s'arrêtent

- Vous êtes à la traîne par rapport à vos concurrents

Pensez-y. Votre pièce en plastique se casse lors d'une démonstration chez un gros client. Et maintenant ? Vous regardez peu professionnelLe client s'éloigne.

Ou peut-être que votre drone s'écrase à cause d'un bras en plastique cassé. Tout ce travail et cet argent… disparu en quelques secondes.

La solution : l'impression 3D en fibre de carbone

Good news! Carbon fiber 3D printing fixes these problems when supported by engineering-grade carbon fiber manufacturing that turns printed designs into reliable, load-bearing parts. With our 28+ years making fibre de carbone produits, nous savons fabriquer des pièces qui :

- Sont très forts

- Restez léger

- Ça dure longtemps

- Ça a l'air bien

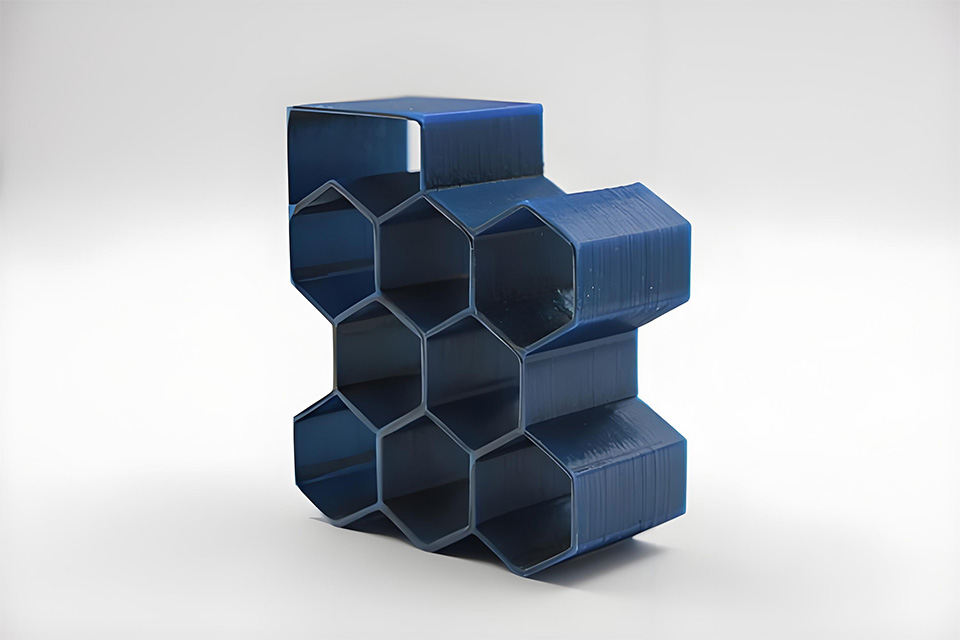

Qu'est-ce que l'impression 3D en fibre de carbone ?

L'impression 3D en fibre de carbone associe de minuscules fibres de carbone à du plastique. Cela permet de fabriquer des pièces :

- 5 fois plus fort que le plastique normal

- 3 fois plus rigide

- Presque aussi léger

Imaginez que vous ajoutiez des tiges d'acier au béton. Les fibres de carbone rendent le plastique beaucoup plus résistant.

Types d'impression 3D en fibre de carbone

Il existe deux principales manières d’imprimer en 3D avec de la fibre de carbone :

1. Filament court en fibre de carbone

C'est le type le plus courant. De petits morceaux de fibre de carbone sont mélangés à du plastique comme le PLA, le nylon ou le PETG.

Bon pour :

- Plus facile à imprimer

- Fonctionne avec de nombreuses imprimantes 3D

- Moins cher au départ

2. Fibre de carbone continue

Il utilise de longs brins de fibre de carbone qui traversent toute la pièce.

Bon pour :

- Beaucoup plus fort parties

- Pièces qui ne doivent pas se casser

- Remplacement des pièces métalliques

Ce dont vous avez besoin pour imprimer en 3D de la fibre de carbone

Pour imprimer avec de la fibre de carbone, vous avez besoin de :

| Article | Pourquoi c'est nécessaire |

|---|---|

| Buse en acier trempé | La fibre de carbone use les buses normales |

| Hotend haute température | Pour fibre nylon-carbone (250°C+) |

| lit chauffant | Aide les pièces à mieux coller |

| Imprimante incluse | Conserve la chaleur pour de meilleures couches |

Meilleures imprimantes 3D pour fibre de carbone

Voici quelques bonnes imprimantes 3D pour la fibre de carbone :

| Imprimante | Taille de construction | Idéal pour |

|---|---|---|

| Raise3D Pro2 Plus | 305 × 305 × 605 mm | Grandes pièces industrielles |

| QIDI Tech X-CF Pro | 300 × 250 × 300 mm | Utilisation en usine |

| Bambu Lab X1E | 256 × 256 × 256 mm | Bonne qualité, moindre coût |

Avantages réels de l'impression 3D en fibre de carbone

1. La force quand vous en avez besoin

Les pièces en fibre de carbone sont beaucoup plus fort que le plastique normal. Cela signifie :

- Plus de bras de drone cassés

- Pièces automobiles capables de supporter de réelles contraintes

- Porte-outils qui ne se cassent pas

Le bras de drone d'un client, fabriqué en plastique ordinaire, s'est cassé en 3 jours. Notre version en fibre de carbone a résisté à 8 mois d'utilisation intensive.

2. Économies de poids

Les pièces en fibre de carbone sont légères mais résistantes. Elles contribuent à :

- Meilleure utilisation du carburant dans voiture en fibre de carbone parties

- Des temps de vol plus longs pour les drones

- Outils et appareils plus faciles à transporter

3. Résistance à la température

Le nylon en fibre de carbone peut supporter des températures beaucoup plus élevées que le plastique normal :

- Fonctionne jusqu'à 180°C (356°F)

- Ne fond pas dans une voiture chaude

- Idéal pour les pièces proches des moteurs

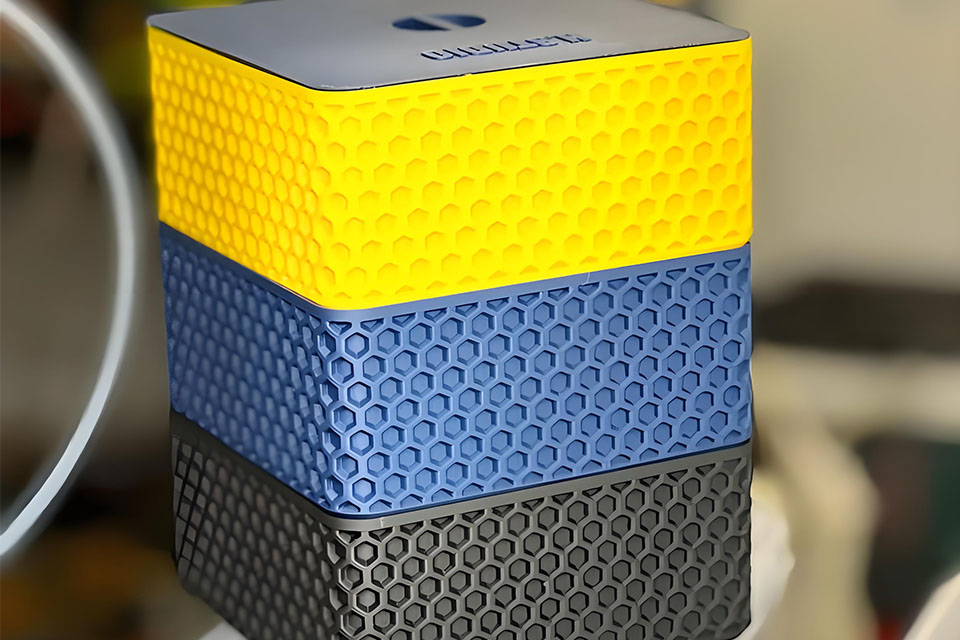

4. Aspect professionnel

La fibre de carbone a une look spécial qui dit « haut de gamme » :

- Foncé avec motif de fibres visible

- Finition mate

- Sensation haut de gamme

C'est pourquoi tant de moto en fibre de carbone les pièces sont superbes.

Problèmes courants et comment les résoudre

Problème : Buses bouchées (42% de problèmes)

La fibre de carbone est agressive pour les imprimantes. Elle peut obstruer les buses.

Notre solution :

- Nous utilisons des buses spéciales en acier trempé

- Nous testons chaque lot de filaments

- Nous avons des paramètres parfaits pour une impression fluide

Problème : Faible liaison des couches (28% de problèmes)

Parfois, les couches ne collent pas bien ensemble.

Notre solution :

- Nous utilisons des réglages de température parfaits

- Nos enceintes personnalisées gardent la chaleur à l'intérieur

- Nous pouvons recuire les pièces après l'impression pour plus de résistance

Problème : Adhérence au lit (18% de problèmes)

Les pièces en fibre de carbone peuvent se déformer et se détacher du lit.

Notre solution :

- Nous utilisons des matériaux de lit testés pour chaque filament

- Notre méthode de préparation au lit fonctionne à chaque fois

- Nous utilisons juste la bonne température de lit

Industries utilisant l'impression 3D en fibre de carbone

Aérospatial

- Pièces de drone

- Composants des satellites

- Équipements d'aéronefs

Un fabricant de drones poids réduit de 55% en passant à notre pièces en fibre de carbone.

Automobile

- Pièces de voiture de course

- Pièces de tableau de bord personnalisées

- Pièces prototypes

Notre fibre de carbone personnalisée les pièces automobiles ont aidé une équipe de course économiser le poids du 63% sur les composants clés.

Médical

- Prothèses

- Outils médicaux

- Boîtiers d'appareils

Les outils d'une entreprise médicale dure 4 fois plus longtemps avec nos pièces en fibre de carbone.

Industriel

- Pièces de robot

- Équipements d'usine

- Outils personnalisés

Une usine économisé $45 000 par an en ne cassant pas les outils en plastique.

Notre avantage en matière de fabrication : plus de 28 ans d’expérience

Forts de plus de 28 ans d'expérience dans la fabrication de produits en fibre de carbone, nous savons ce qui fonctionne. Notre usine en Chine propose :

- Conception entièrement personnalisée:Nous vous aidons à transformer vos idées en pièces réelles

- Contrôle de qualité: Inspection 100% sur toutes les pièces

- Délai d'exécution rapide:Livraison en 2 à 3 semaines sur la plupart des commandes

- Échelle:Nous pouvons fabriquer 1 pièce ou 10 000

Économies de coûts grâce à l'impression 3D en fibre de carbone

L'impression 3D en fibre de carbone permet d'économiser de l'argent par rapport à d'autres méthodes :

Usinage des métaux : $$$$$$$$$$$$$$$ 100Couche de fibre de carbone % : $$$$$$$$$$ 85Fibre de carbone % 3D Impression : $$$$$$ 40-65%

Un client fabriquant des supports métalliques est passé à nos pièces imprimées en 3D en fibre de carbone et économisé 55% sur les coûts.

Comment démarrer avec nous

Travailler avec nous est simple :

- Envoyez-nous votre idée ou votre fichier 3D

- Nous l'examinons et suggérons la meilleure approche

- Nous réalisons un échantillon pour votre approbation

- Nous commençons la production lorsque vous êtes satisfait

Étude de cas : Entreprise de drones de course

Une entreprise de drones de course avait un gros problèmeLeurs bras en plastique se cassaient sans cesse lors des atterrissages en catastrophe. Les pilotes étaient mécontents. Les ventes étaient en baisse.

Ce nuire à leur entreprise C'était vraiment mal. Ils dépensaient trop d'argent en remplacements. Leur marque paraissait bon marché.

Nous les avons faits bras imprimés en 3D en fibre de carbone que:

- Nous étions 3 fois plus forts

- Resté au même poids

- Coûte seulement 15% de plus que le plastique

- Avait un look carbone cool

Résultats: La casse a diminué 94%. La satisfaction des clients a augmenté. Ils économisé $23,000 au cours de la première année sur les réclamations de garantie.

Étude de cas : fabricant de dispositifs médicaux

Une entreprise d'outils médicaux proposait des manches en plastique qui :

- Cassé trop facilement

- Ne peut pas être nettoyé avec des produits chimiques puissants

- Ça avait l'air bon marché

Ce porté atteinte à leur réputation avec des médecins. Ils ont perdu des ventes au profit des fabricants d'outils en métal.

Nous avons créé des poignées en nylon et fibre de carbone qui :

- Nous sommes forts comme le métal

- Résiste aux produits chimiques de nettoyage

- J'avais une sensation de qualité supérieure

- Pesait moins que le métal

Résultats:Les ventes ont augmenté de 34%. Les médecins ont préféré les nouveaux outils. Ils ont facturé 20% de plus pour la sensation premium.

Pourquoi nous choisir comme partenaire d’impression 3D en fibre de carbone ?

- Plus de 28 ans d'expérience:Nous connaissons la fibre de carbone mieux que quiconque

- Experts OEM/ODM: Nous fabriquons des pièces selon vos besoins exacts

- Service complet: Aide à la conception, prototypes et production

- Contrôle de qualité: Chaque pièce a été vérifiée 3 fois

- Prix compétitifs:Directement de notre usine en Chine

Prêt à fabriquer des pièces plus solides ?

Ne laissez plus les pièces en plastique fragiles nuire à votre entreprise. Notre impression 3D en fibre de carbone résout définitivement ces problèmes.

Contactez-nous dès aujourd'hui pour un devis gratuit. Envoyez-nous votre fichier 3D ou simplement votre idée. Nous vous montrerons comment la fibre de carbone peut améliorer vos pièces.

E-mail: [email protected] Téléphone: +86-136 2619 1009 Site web: https://chinacarbonfibers.com