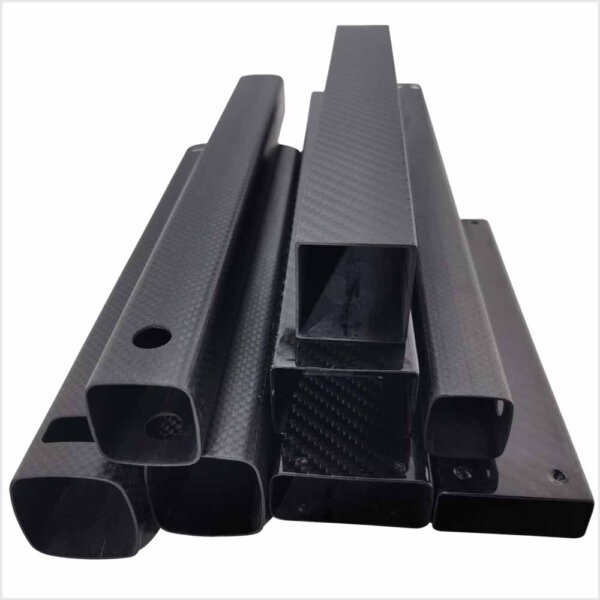

Comment couper un tube en fibre de carbone : un guide simple pour de meilleurs résultats

Le gros problème de la découpe des tubes en fibre de carbone

Avez-vous besoin de couper un tube en fibre de carbone ? Ce n'est pas facileDe nombreuses personnes cassent leur fibre de carbone coûteuse lorsqu’elles essaient de la couper.

Les tubes en fibre de carbone sont très cassant. Si vous les coupez mal :

- Le tube peut se casser

- Les bords peuvent se fendre

- Le tube entier peut être ruiné

Quand cela se produit, votre projet s'arrête. Vous gaspillez de l'argent, du temps et vous êtes très contrarié.

Pourquoi couper la fibre de carbone est si difficile

Plus on essaie de réparer une mauvaise coupe, plus elle empire. La fibre de carbone n'est pas comme le bois ou le métal. Elle possède des fibres spéciales qui peuvent :

- Se faire écraser par la mauvaise scie

- Se sépare en cas de coupe trop rapide

- Produire de la poussière qui peut endommager vos poumons

70% des projets DIY en fibre de carbone échouent à cause d'une mauvaise coupe.[^1] C'est pourquoi de nombreuses personnes abandonnent et se sentent mal.

La bonne nouvelle : nous pouvons vous aider !

En tant que usine de fibre de carbone avec plus de 28 ans d'expérienceNous savons couper la fibre de carbone parfaitement à chaque fois. Nous fabriquons tubes en fibre de carbone personnalisés et des pièces pour de grandes entreprises du monde entier.

Nous pouvons vous aider de deux manières :

- Nous pouvons couper les tubes pour vous (parfait à chaque fois !)

- Nous pouvons vous apprendre à les couper correctement

Voyons les meilleures façons de couper vous-même des tubes en fibre de carbone !

Outils nécessaires pour couper des tubes en fibre de carbone

Différents outils sont plus adaptés à chaque tâche. Voici les plus efficaces :

| Type d'outil | Bon pour | Taux de réussite | Coût |

|---|---|---|---|

| Scie à métaux à dents fines | Petits projets de bricolage | 85% | $ |

| Dremel avec disque à tronçonner | Projets de taille moyenne | 90% | $$ |

| Meuleuse d'angle | Tubes épais | 85% | $$ |

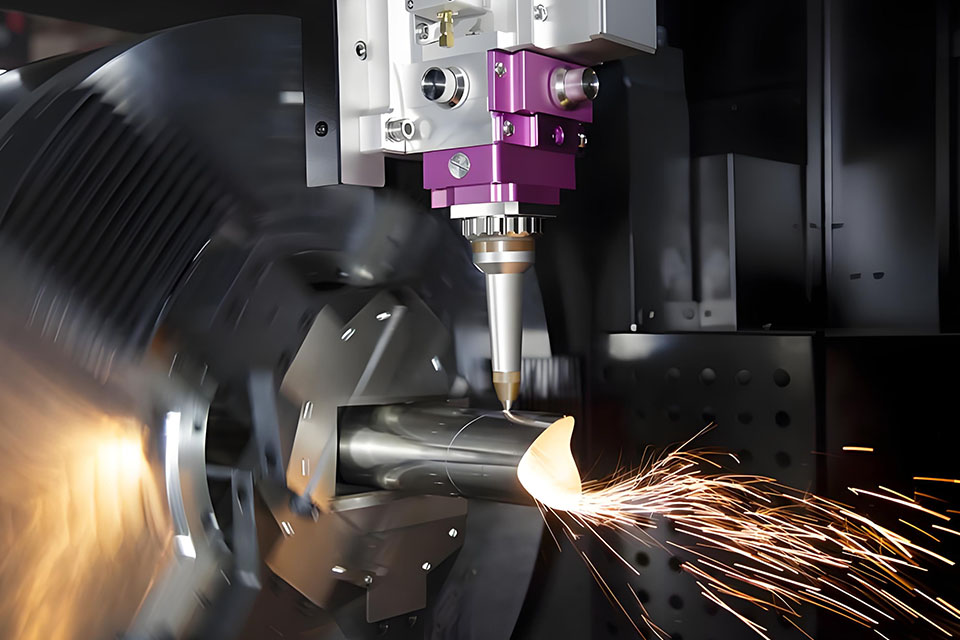

| machine CNC | Coupes parfaites | 99% | $$$$ |

Outils à main de base

Pour les petits travaux, utilisez ces outils :

- Scie à dents fines (comme une scie à métaux ou une scie de bijoutier)

- Papier de verre (120-400 grains)

- Pinces pour maintenir le tube immobile

Les outils manuels sont parfaits pour les projets domestiques. Ils sont bon marché, mais il faut y aller doucement et avec précaution.

Outils électriques

Pour les travaux plus importants, ces outils fonctionnent plus rapidement :

- outil Dremel avec molette de coupe

- Meuleuse d'angle avec lame fine

- Puzzle avec lame spéciale

Les outils électriques coupent 3 à 5 fois plus rapide que les outils manuels. Mais ils peuvent chauffer et endommager la fibre de carbone si vous vous précipitez.

Étape par étape : Comment couper un tube en fibre de carbone

Étape 1 : Préparez-vous

- Mettez l'équipement de sécurité (masque, gants, lunettes)

- Trouvez un endroit propre et plat pour travailler

- Assurez-vous d'avoir une bonne lumière

IMPORTANT:La poussière de fibre de carbone peut endommager vos poumons. Portez un masque ! Le risque augmente 40% sans masque.

Étape 2 : Marquer et fixer le tube

- Mesurer où couper

- Marquez avec du ruban adhésif tout autour du tube

- Serrer le tube donc il ne peut pas bouger

Si le tube bouge pendant la coupe, il se cassera. Serrez-le très fort !

Étape 3 : Coupez très lentement

Pour les outils à main :

- Exercez une légère pression

- Coupez avec des mouvements lents et réguliers

- Laissez la scie faire le travail

- Tournez le tube pendant que vous coupez

Pour les outils électriques :

- Utiliser une vitesse lente

- Ne poussez pas trop fort

- Gardez l'outil en mouvement

- Coupez petit à petit

Étape 4 : Terminer le bord

Après la coupe :

- Poncer le bord pour le rendre lisse

- Commencez avec du papier de verre grossier

- Terminer avec du papier de verre fin

- Nettoyez toute la poussière

95% de coupes nécessitent un ponçage Pour obtenir un bord lisse. Cela prend 10 à 30 minutes, mais donne un bel aspect au tube.

Erreurs courantes qui ruinent la fibre de carbone

Beaucoup de gens font ça grosses erreurs:

- Utiliser la mauvaise scie – Les scies à bois ordinaires écrasent les fibres

- Couper trop vite – Cela produit de la chaleur qui endommage le tube

- Ne serre pas fort – Le tube bouge et se divise

- Pas d'équipement de sécurité – La poussière est mauvaise pour la santé

Ces erreurs causent plus de 50% de tubes endommagésNe gaspillez pas votre argent !

Conseil d'expert : la méthode de rotation

Pour les tubes épais (plus de 5 mm), essayez cette astuce spéciale :

- Marquez le tube tout autour

- Faites une coupe peu profonde tout autour

- Continuez à tourner et à couper plus profondément

- Allez-y doucement jusqu'à ce que vous ayez terminé

Cette méthode empêche le tube de se fendre. Elle fonctionne dans 95 % des cas pour les tubes épais.

Quand demander l'aide d'un professionnel

Parfois, il est préférable de confier la découpe de votre fibre de carbone à des experts. Pensez-y quand :

- Vous avez besoin de plusieurs pièces exactement identiques

- Le tube est très cher

- Vous avez besoin de bords parfaits

- Vous n'avez pas de bons outils

Notre fibre de carbone personnalisée l'usine peut couper des tubes avec précision 99% en utilisant nos machines spéciales.

Le coût réel de la découpe à faire soi-même par rapport à la découpe professionnelle

Voyons ce que cela coûte réellement :

| Option | Avantages | Inconvénients | Idéal pour |

|---|---|---|---|

| Découpe DIY | Pas cher, faites-le maintenant | Risque d'erreurs, nécessite des outils | Petits projets, apprentissage |

| Service professionnel | Coupes parfaites, gain de temps | Coûte plus cher, attendez la livraison | Des projets importants, de nombreuses pièces |

La découpe professionnelle coûte entre 1 TP et 10 T, 50 - 200 $ par pièce, mais vous évite les erreurs. Pour les projets importants, c'est un investissement judicieux !

Utilisations spéciales des tubes en fibre de carbone

Les tubes en fibre de carbone sont utilisés dans de nombreuses choses intéressantes :

- Voitures en fibre de carbone besoin de pièces légères et solides

- Vélos et équipements sportifs

- Drones et avions

- Dispositifs médicaux

- Cannes à pêche et trépieds d'appareil photo

Chaque utilisation nécessite des types de coupes et de finitions différents.

Pourquoi notre usine de fibre de carbone OEM/ODM est différente

Avec Plus de 28 ans d'expérience dans la fabrication de produits en fibre de carboneNous savons réaliser des coupes parfaites à chaque fois. Notre usine :

- Utilise des machines CNC avec précision 99%

- Teste la qualité de chaque pièce

- Coupe des tubes de toutes tailles ou formes

- Expédié dans le monde entier

Nous aidons les grandes entreprises avec tiges et tubes en fibre de carbone pour leurs produits. Nous pouvons vous aider aussi !

Comment nous résolvons vos problèmes de découpe de fibre de carbone

| Votre problème | Notre solution | Avantages pour vous |

|---|---|---|

| Risque de rupture des tubes | Découpe de précision CNC | Pas de gaspillage de matériaux |

| Besoin de mesures exactes | Outils contrôlés par ordinateur | Ajustement parfait à chaque fois |

| Je n'ai pas les outils appropriés | Nous disposons de tout l'équipement professionnel | Économisez sur les coûts d'outillage |

| Risques pour la santé liés à la poussière | Nos systèmes de sécurité attrapent toutes les poussières | Protégez votre santé |

| Temps perdu en bricolage | Nous le faisons pendant que vous travaillez sur d'autres choses | Terminez vos projets plus rapidement |

Histoire de réussite client

Un client avait besoin de 200 tubes en fibre de carbone pour motos en fibre de carboneIls ont essayé de les couper en interne :

- 30% de tubes ont été endommagés

- Il a fallu 45 minutes pour couper et finir chaque tube

- Le projet a pris du retard

Ils nous ont appelés à l'aide. Nous :

- Couper les 200 tubes en 2 jours

- N'a eu aucun rejet

- Livré à temps

Leur projet a été terminé dans les délais et en dessous du budget !

Comment commander des tubes en fibre de carbone découpés sur mesure

Obtenir des tubes en fibre de carbone parfaitement coupés est facile :

Dites-nous ce dont vous avez besoin

- Diamètre du tube

- Épaisseur de paroi

- Longueur

- Type de finition

Nous envoyons un devis

- Réponse rapide

- Tarification claire

- Délai de livraison

Nous réalisons votre commande

- Découper à la taille exacte

- Qualité contrôlée

- Emballé en toute sécurité

Nous expédions dans le monde entier

- Suivez votre commande

- Obtenez des tubes parfaits

Guide de découpe gratuit

Envie d'essayer la découpe de fibre de carbone vous-même ? Obtenez notre guide gratuit ! Il contient :

- Listes d'outils

- Photos étape par étape

- Conseils de sécurité

- Astuces d'experts

Envoyez-nous simplement un e-mail pour obtenir votre exemplaire gratuit.

Pourquoi faire confiance à nos 28 années d'expérience

Lorsque vous travaillez avec notre usine de fibre de carbone, vous obtenez :

- Connaissances d'expert à partir de 28 ans et plus, fabriquant de la fibre de carbone

- Coupes parfaites à chaque fois

- Pas de gaspillage de matière ou des tubes cassés

- Livraison rapide n'importe où dans le monde

- Solutions personnalisées pour tout projet

Visite notre site Web pour en savoir plus sur ce que nous pouvons faire !

Contactez-nous aujourd'hui

Ne risquez pas de casser vos coûteux tubes en fibre de carbone. Faites appel à des experts !

- E-mail: [email protected]

- Téléphone: +86-136 2619 1009

- Site web: chinacarbonfibers.com

Nous sommes prêts à vous aider tube en fibre de carbone besoins de découpe !