Plastique renforcé de fibre de carbone : solide et léger

Qu'est-ce que le plastique renforcé de fibres de carbone ?

Le plastique renforcé de fibres de carbone (PRFC) est un fort, lumière Matériau. Il est composé de fibres de carbone mélangées à du plastique. Ce plastique est appelé résine. Ensemble, ils forment quelque chose. incroyable.

Le gros problème

Vous fabriquez des voitures, des avions ou des équipements sportifs ? Alors vous connaissez le problème.

Les pièces métalliques sont trop lourdes.

Les pièces lourdes signifient :

- Les voitures qui consomment trop d'essence

- Des avions qui ne peuvent pas voler aussi loin

- Des équipements de sport qui vous ralentissent

Quand les choses sont lourdes, elles coûtent plus cher et nuisent aussi à notre planète.

Pourquoi cela est si important

Le problème s'aggrave de jour en jour. Le prix de l'essence augmente. Les gens veulent aller plus vite et plus loin. Vos clients veulent de meilleurs produits maintenant!

Si vous continuez à utiliser des matériaux lourds :

- Vos coûts augmenteront

- Vos produits ne se vendront pas bien

- Votre entreprise pourrait prendre du retard

Ce n'est pas un petit problème. Il devient de plus en plus grand.

La solution parfaite : le plastique renforcé de fibres de carbone

Fibre de carbone est la réponse ! C'est :

- 5 fois plus fort que l'acier

- Briquet 70% que l'acier

- Ne rouille pas comme du métal

Avec nos 28 ans et plus de fabrication de pièces en fibre de carbone en Chine, nous pouvons vous aider à résoudre ces problèmes rapidement !

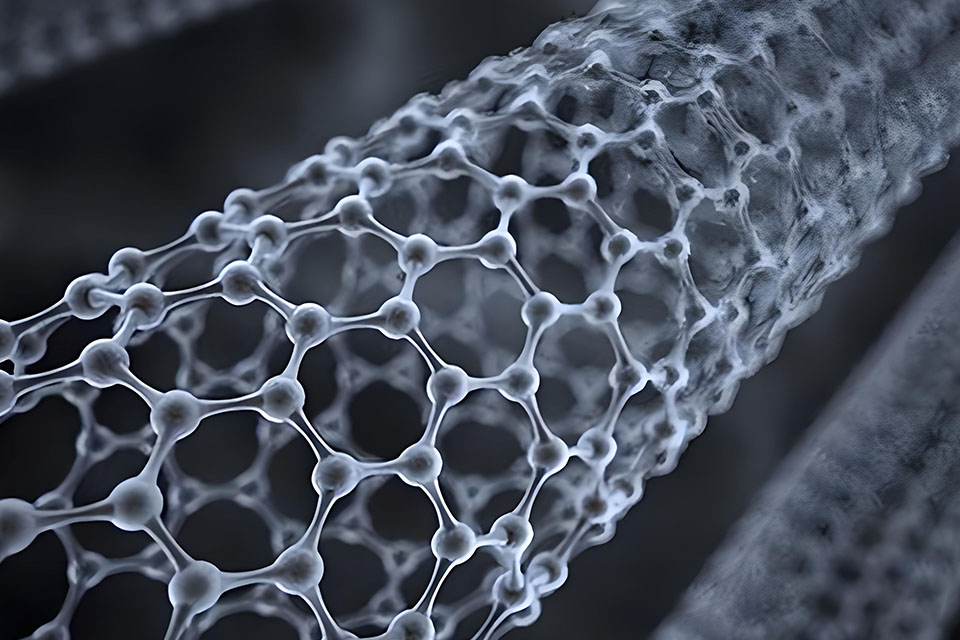

Comment fonctionne la fibre de carbone

La fibre de carbone est composée de minuscules fils de carbone. Ces fils sont plus fins qu'un cheveu humain ! Nous les enfermons dans du plastique. Le plastique maintient le tout ensemble.

Cela permet de fabriquer des pièces qui sont :

- Super fort

- Très léger

- Ça a l'air génial

Le marché croissant de la fibre de carbone

Regardez à quelle vitesse ce marché se développe :

| Année | Taille du marché | Taux de croissance |

|---|---|---|

| 2024 | $13,46 milliards | Point de départ |

| 2030 | $45,01 milliards | 21,7% par an |

Le marché va plus que tripler en seulement six ans !

Qui utilise la fibre de carbone ?

De nombreuses grandes entreprises utilisent la fibre de carbone pour des choses importantes :

1. Voitures et camions

Pièces automobiles en fibre de carbone améliorer les véhicules :

- Plus léger les voitures consomment moins d'essence

- Plus fort les pièces assurent la sécurité des personnes

- Ne rouille pas comme des pièces métalliques

Étude de casLa BMW i3 est dotée d'une carrosserie en fibre de carbone. Cela la rend plus légère et lui permet d'aller plus loin avec une seule charge.

2. Avions

Les avions modernes ont besoin de fibre de carbone :

- Fabrique des avions plus léger

- Aide à l'utilisation moins de carburant

- Fabrique des pièces qui durer plus longtemps

Étude de casLe 787 Dreamliner de Boeing est fabriqué en fibre de carbone 50%. Cela lui permet de consommer 20% de carburant de moins que les autres avions de sa taille.

3. Équipement sportif

Moto en fibre de carbone pièces et équipements sportifs :

- Des raquettes de tennis qui frappent Plus fort

- Des vélos qui roulent plus rapide

- Des clubs de golf qui frappent plus loin

4. Énergie éolienne

Pales d'éoliennes en fibre de carbone :

- Peut être plus gros que ceux en métal

- Attraper plus de vent

- Faire plus de puissance

Étude de cas:Siemens fabrique des pales d'éoliennes en fibre de carbone de 108 mètres qui sont 15% plus efficaces que celles en métal.

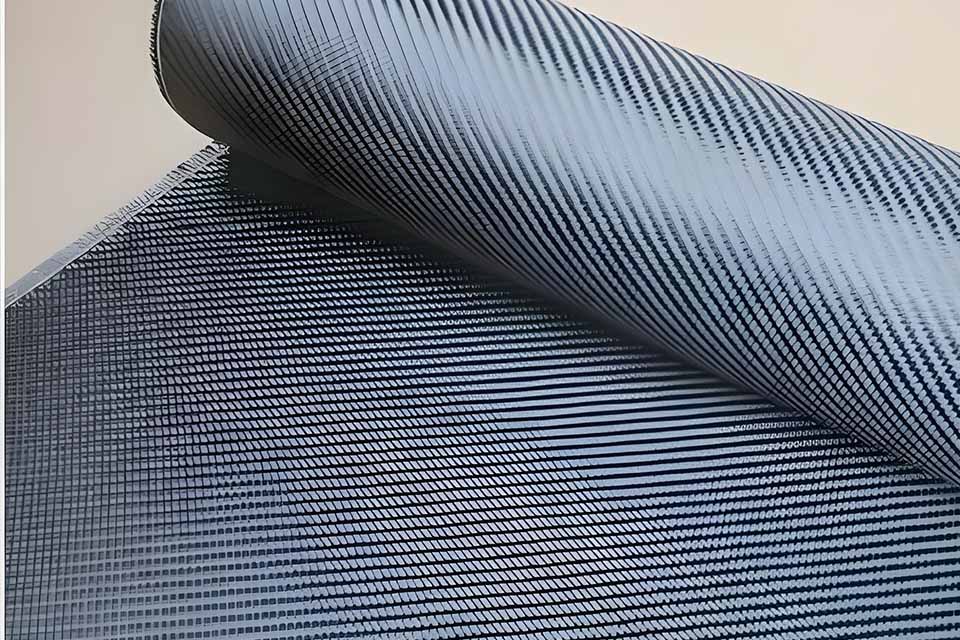

Types de produits en fibre de carbone

Nous pouvons réaliser de nombreux types différents :

- PRFC vierge – Le type le plus fort

- PRFC recyclé – Meilleur pour la terre

- CFRP hybride – Mélangé avec d’autres matériaux pour économiser de l’argent

Pourquoi notre entreprise est différente

Avec 28+ ans fabriquer des produits en fibre de carbone, nous savons comment le faire correctement !

Nos points forts :

- Conceptions personnalisées qui correspondent exactement à vos besoins

- Services OEM/ODM afin que vous puissiez vendre sous votre marque

- Contrôle de qualité qui répond aux normes mondiales

- Livraison rapide partout dans le monde

- Des prix équitables qui aident votre entreprise à se développer

Le processus de fabrication

Comment faisons-nous fibre de carbone personnalisée parts? This is achieved through CFRP component manufacturing, here’s our simple process:

- Conception – Nous travaillons avec vous pour créer le design parfait

- Fabrication de moules – Nous construisons des moules sur mesure pour vos pièces

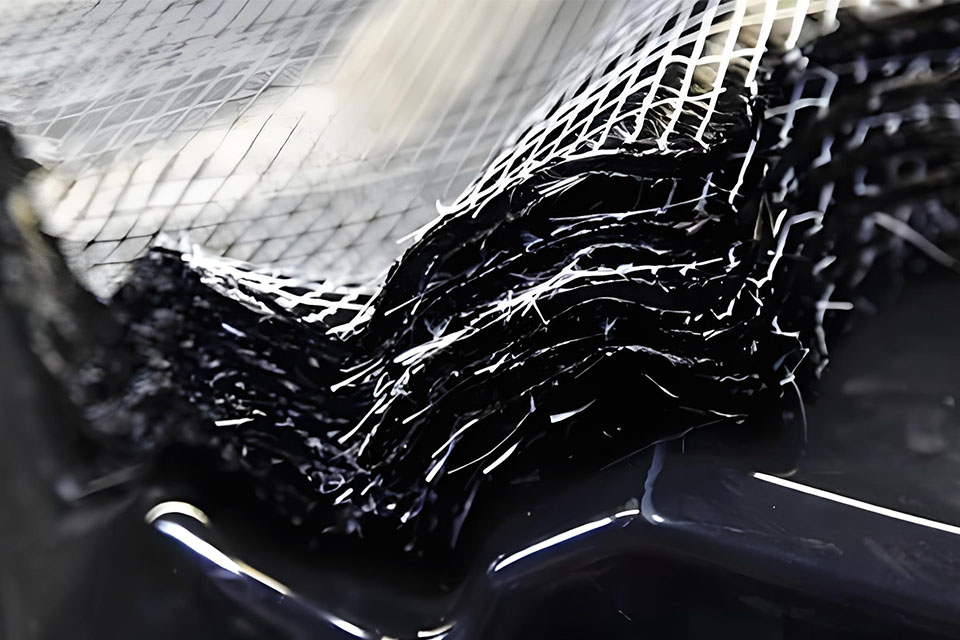

- Couche de fibre de carbone – Nous mettons de la fibre de carbone dans le moule

- Application de résine – Nous ajoutons le plastique spécial

- Durcissement – Nous le chauffons pour le rendre plus fort

- Finition – Nous le rendons parfait

- Essai – Nous nous assurons qu’il est suffisamment solide

- Expédition – Nous vous l’envoyons rapidement

Avantages pour différentes industries

Pour les constructeurs automobiles :

- 70% plus léger pièces que du métal

- 5 fois plus fort que l'acier

- Pièces qui ne rouille pas

- Conceptions personnalisées pour tout modèle de voiture

- Production rapide pour les nouveaux modèles

Pour les compagnies aériennes :

- Super léger les pièces permettent d'économiser du carburant

- Très fort pour la sécurité

- Formes personnalisées pour une meilleure circulation de l'air

- Résistant au feu options

- Longue durée parties

Pour les entreprises du secteur sportif :

- Poids léger pour de meilleures performances

- Fort pour la sécurité

- Formes personnalisées ça a l'air cool

- Se sentir bien lorsqu'il est utilisé

- Dure plus longtemps que d'autres matériaux

Coûts et avantages

La fibre de carbone coûte plus cher que le métal au départ. Mais pensez aux économies suivantes :

- Consommer moins de carburant parce que les pièces sont plus légères

- Remplacez moins de pièces parce qu'ils durent plus longtemps

- Chargez plus pour de meilleurs produits

- Expédiez pour moins cher parce que les pièces sont plus légères

- Meilleur pour la terre à long terme

Ce que disent nos clients

« Nous sommes passés aux pièces en fibre de carbone et nos vélos sont devenus plus légers (30%). Nos ventes ont augmenté de 45% l'an dernier ! » – Propriétaire d'une entreprise de vélos

« Les pièces automobiles en fibre de carbone sont superbes et nos clients les adorent. Les commandes ont augmenté de 25% ! » – Concessionnaire de pièces automobiles

« Nous avions besoin de formes spéciales pour notre nouveau drone. Ils les ont réalisées parfaitement du premier coup ! » – PDG d'une entreprise technologique

Comment commencer à utiliser la fibre de carbone

Il est facile de commencer à utiliser la fibre de carbone dans vos produits :

- Dites-nous ce dont vous avez besoin – Envoyez vos idées ou dessins

- Obtenez un devis gratuit – Nous vous indiquerons le coût et le délai

- Voir un échantillon – Nous en ferons un pour que vous puissiez le vérifier

- Démarrer la production – Nous en fabriquerons autant que vous en aurez besoin

- Recevez des expéditions régulières – Nous continuerons à envoyer selon votre calendrier

L'avenir de la fibre de carbone

Le marché de la fibre de carbone va poursuivre sa croissance rapide ! D'ici 2037, il atteindra 10,60 milliards de livres sterling.

Les nouvelles technologies permettront de fabriquer de la fibre de carbone :

- Moins cher produire

- Plus rapide faire

- Mieux pour la terre

Croissance du marché régional

| Région | Principaux domaines de croissance | Qu'est-ce qui stimule la croissance? |

|---|---|---|

| Amérique du Nord | Aérospatiale, Défense | Dépenses publiques, entreprises technologiques |

| Asie-Pacifique | Voitures, motos | Classe moyenne en pleine croissance, nouvelles usines |

| Europe | Énergie éolienne, Sports | Règles sur l'énergie propre et marché du sport |

L’Asie-Pacifique connaîtra la plus forte croissance d’ici 2037 !

Questions courantes sur la fibre de carbone

La fibre de carbone est-elle plus résistante que l’acier ?

Oui ! La fibre de carbone est environ cinq fois plus résistante que l'acier en termes de poids.

Combien de temps dure la fibre de carbone ?

Les pièces en fibre de carbone peuvent durer 20