Ultimate Lightweight Carbon Fiber Snowboard For Mountain Magic

Bienvenue dans le monde de top tier snowboarding! Nos snowboards customisés en fibre de carbone sont conçus pour les riders qui veulent le meilleur matériel pour la montagne. Nous fabriquons ces planches dans notre usine spéciale avec les meilleurs matériau en fibre de carbone. Ces tableaux sont super léger mais très résistants. Ils permettent d'aller vite et d'avoir un meilleur contrôle sur la neige.

Pourquoi choisir nos snowboards ? Parce que nous les fabriquons pour vous ! Notre équipe utilise la technologie aérospatiale pour fabriquer des planches qui donnent l'impression d'avoir été conçues pour vos pieds. Des pièces de voiture aux avions spatiaux, nous savons comment travailler avec la fibre de carbone. Aujourd'hui, nous appliquons ce savoir-faire à votre snowboard.

Comment notre construction de snowboard en fibre de carbone légère vous rend meilleur

Nos planches ne se contentent pas d'avoir l'air cool, elles fonctionnent aussi mieux ! La construction en fibre de carbone des snowboards que nous utilisons les rend plus légères que les autres planches mais toujours très résistante. Cela signifie que vous pouvez rouler plus longtemps sans vous fatiguer. Lorsque nous fabriquons un snowboard, nous plaçons de la fibre de carbone aux bons endroits. Cela donne à la planche le modèle de flex parfait. Votre planche se plie quand vous le souhaitez, mais reste rigide quand vous en avez besoin. Le résultat ? Vous pouvez prendre des virages serrés et atterrir sur de gros sauts avec facilité.

Le matériau en fibre de carbone permet également d'amortir les vibrations sur la neige rugueuse. Cela signifie une conduite en douceur, même lorsque la pente devient cahoteuse. De nombreux riders nous disent qu'ils ont l'impression de flotter sur nos planches !

La façon dont nous concevons nos planches fait toute la différence. Nous ne nous contentons pas de coller de la fibre de carbone et de dire que c'est fait. Nous étudions votre façon de rider et fabriquons des planches qui vous aident à repousser ses limites. Notre équipe de conception utilise des modèles informatiques pour trouver le profil parfait pour chaque type de conduite. Que vous aimiez le all-mountain cruising ou les figures de freestyle, nous avons un design qui vous fera sourire.

La pointe et le tail de nos planches ont un tissage spécial en fibre de carbone qui vous donne un pop incroyable. Lorsque vous voulez sauter, ces planches vous propulsent dans les airs ! Mais elles sont aussi stables à haute vitesse quand tu veux aller vite. Nous nous assurons également que les zones de fixation sont très solides. Cela permet d'améliorer la tenue de carre et la réactivité. Tu le penses, la planche le fait - c'est la rapidité de réaction de ces snowboards !

Des avancées technologiques dans la fabrication de fibres de carbone pour de meilleures planches à neige

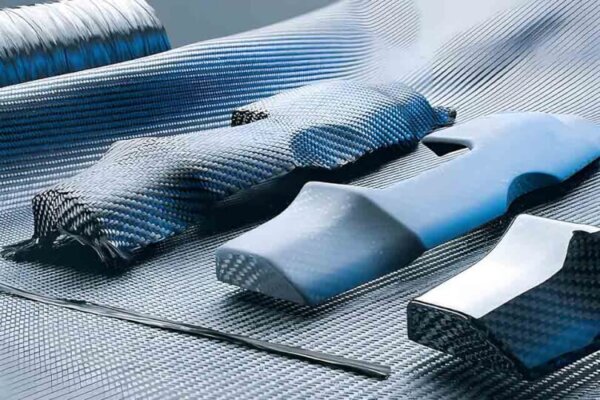

Notre processus de fabrication est ce qui nous distingue. Nous ne nous contentons pas de suivre le peloton, nous le devançons en proposant de nouvelles méthodes de travail avec la fibre de carbone. Dans notre usine, nous utilisons de véritables brins de fibre de carbone, et non des imitations bon marché. Vous pouvez réellement voir les le tissage de carbone à travers la feuille supérieure transparente. Ce n'est pas qu'une question d'apparence - cela montre les matériaux composites de haute qualité que nous utilisons.

Le filament de carbone que nous utilisons provient des mêmes fournisseurs que ceux qui fabriquent des pièces pour les entreprises aérospatiales. Cela signifie que votre snowboard a le même rapport poids/résistance que les pièces d'avion !

Nous utilisons également une technique spéciale pour ajouter de la rigidité en torsion sans rendre la planche trop rigide. Vous obtenez ainsi une planche qui est léger et puissant et facile à manœuvrer.

Types de cartes que nous proposons

| Type de carte | Idéal pour | Disposition de la fibre de carbone | Cote de flexion |

|---|

| Toutes montagnes | Une conduite polyvalente | Longueur totale en carbone | Moyen |

| Style libre | Tours et sauts | Pointe double avec inserts en carbone | Moyennement doux |

| Freeride | Poudre et vitesse | Disposition directionnelle du carbone | Moyennement rigide |

| Débutant | Les bases de l'apprentissage | Placement stratégique du carbone | Doux |

| Modèle Pro | Coureurs expérimentés | Modèle de carbone personnalisé | Personnalisable |

Ce que disent nos cavaliers

"J'ai essayé beaucoup de planches, mais rien n'arrive à la cheville de cette planche en fibre de carbone. C'est comme si la planche lisait dans mes pensées !" - Jake, snowboarder professionnel

"La conception légère a fait toute la différence lors de mon dernier voyage. Je pouvais rouler toute la journée sans que mes jambes ne s'épuisent." - Sarah, guide de montagne

Pourquoi la fibre de carbone fait-elle de meilleurs snowboards ?

- Une force incroyable sans poids lourd

- Plus réactif tourne et saute

- Plus durable que les matériaux traditionnels

- Meilleure absorption des vibrations pour une conduite en douceur

- Modèles de flexion personnalisés pour votre style de conduite

Notre processus de fabrication avancé comprend

- Précision découpe de feuilles de fibre de carbone

- Placement minutieux des brins de carbone pour une résistance optimale

- Collage sous vide pour une adhérence parfaite

- Pressage contrôlé par ordinateur pour une qualité constante

- Finition à la main par des artisans qualifiés

- Tests rigoureux sur de vraies montagnes

La beauté de nos planches est que vous pouvez voir le matériau carbone réel. Chaque planche montre l'incroyable motif de tissage qui lui confère sa solidité. Ce n'est pas seulement une question d'apparence - c'est une preuve de la qualité de votre planche.

Des spécifications techniques qui comptent

Lorsque vous choisissez nos snowboards, vous obtenez des spécifications qui comptent vraiment :

- Poids20-30% plus légères que les planches standard

- DurabilitéDurée de vie 2 à 3 fois plus longue

- Temps de réponse: Transition quasi instantanée d'un bord à l'autre

- Amortissement des vibrations: Réduit la fatigue des pieds jusqu'à 60%

Nous utilisons le même matériaux en fibre de carbone qui sont utilisés dans les voitures de course et motos en fibre de carbone. Cela signifie que votre carte bénéficie de décennies de recherche dans le monde de l'automobile.

Options personnalisées pour les amateurs de snowboard

Chaque rider est différent, alors pourquoi toutes les planches devraient-elles être identiques ? Nous proposons des options personnalisées pour ceux qui savent ce qu'ils veulent :

- Indices de flexion personnalisés

- Graphiques personnalisés

- Ajustement de la largeur en fonction de la pointure de la chaussure

- Modèles spéciaux d'inserts de reliure

- Profils de carrossage uniques

Notre usine de carbone peut apporter ces modifications sans perdre les avantages fondamentaux de la construction en fibre de carbone. C'est quelque chose que les grandes surfaces ne peuvent pas offrir.

Lorsque vous commandez chez nous, vous n'achetez pas seulement une planche, vous participez au processus de conception. Nous vous parlons de.. :

- Votre taille et votre poids

- Votre style de conduite

- Vos montagnes préférées

- Votre niveau de compétence

- Vos objectifs pour la saison

Notre équipe utilise ensuite ces informations pour créer la planche parfaite. C'est comme si vous aviez un tableau construit spécialement pour vous - parce que c'est le cas !

L'avantage du carbone pour les différents types de conducteurs

| Type de coureur | Comment la fibre de carbone aide |

|---|

| Débutants | Un poids plus léger facilite l'apprentissage |

| Intermédiaire | Pardonner en réagissant suffisamment pour s'améliorer |

| Avancé | Contrôle de précision pour la conduite technique |

| Rats des parcs | Un pop étonnant pour des sauts plus importants |

| Chiens de chasse à la poudre | Flottement et contrôle dans la neige profonde |

Nous avons travaillé avec constructeurs automobiles pour apprendre à fabriquer des pièces en fibre de carbone capables de résister à des chocs violents. Ces connaissances nous permettent de fabriquer des snowboards capables de supporter de grosses chutes et des atterrissages brutaux.

Pourquoi choisir un fabricant de fibre de carbone sur mesure ?

Toutes les fibres de carbone ne sont pas égales. En tant que spécialiste fibre de carbone personnalisée nous offrons des avantages que d'autres ne peuvent pas offrir :

- Accès direct aux ingénieurs qui conçoivent votre carte

- Contrôle de la qualité à chaque étape

- Pas de marge intermédiaire

- Les dernières technologies en matière de fibres de carbone

- Soutien continu et conseils de mise au point

Notre expérience dans la fabrication de pièces pour l'aérospatiale, l'équipement sportif et l'équipement médical signifie que nous comprenons mieux comment travailler avec la fibre de carbone que les entreprises qui ne fabriquent que des snowboards.

Le processus de fabrication : Des brins aux pentes

La fabrication d'un snowboard en fibre de carbone demande des compétences et du soin :

- Nous commençons par un filament de carbone de première qualité

- Créer des motifs de tissage personnalisés pour différentes zones de la planche

- Combinez avec d'autres matériaux comme les noyaux en bois pour une sensation parfaite.

- Utiliser des résines spéciales qui lient tous les éléments entre eux

- Moules à presser adaptés à votre style de conduite

- Durcissement à des températures précises

- Finition manuelle des bords et des surfaces

- Test de flexion et de résistance Ce processus détaillé est la raison pour laquelle nos planches sont plus performantes en montagne. Nous ne brûlons aucune étape.

Prêt pour votre snowboard en fibre de carbone personnalisé ?

Imaginez que vous vous élanciez sur la piste avec une planche qui fait partie de votre corps. Une planche qui est légère sur le lift mais solide sur la neige. Une planche adaptée à votre façon de rider.

C'est ce que nous proposons. Pas seulement un snowboard, mais un outil sur mesure pour les joies de la montagne. Grâce à notre fibre de carbone de qualité aérospatiale et à des années de savoir-faire en matière de fabrication, nous fabriquons des planches qui vous aident à mieux rider.

Contactez-nous dès aujourd'hui pour commencer à concevoir votre propre snowboard en fibre de carbone. Parlez-nous de votre style de glisse, et nous vous montrerons comment la fibre de carbone peut amener votre snowboard à de nouveaux sommets !

Résumé : Nos snowboards customisés en fibre de carbone haut de gamme offrent des performances de conquête des montagnes avec des matériaux de qualité aérospatiale, ce qui se traduit par des planches incroyablement légères et puissantes à la fois. Faites l'expérience d'une réactivité inégalée, de flexions parfaites et d'une conduite fluide qui transformeront votre temps sur les pistes.