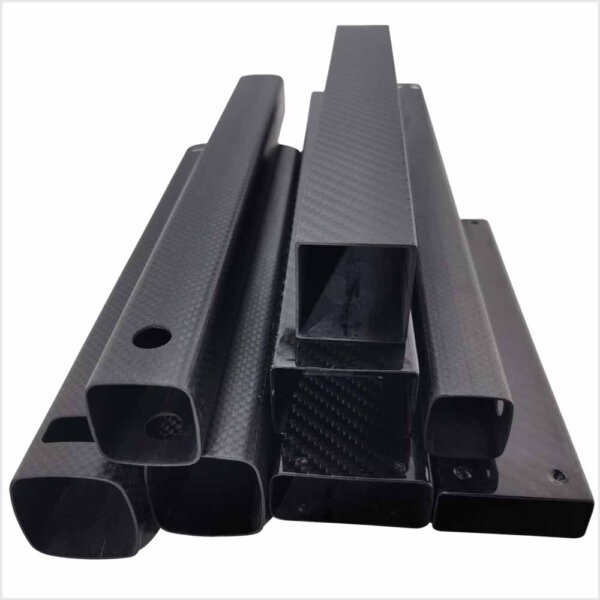

炭素繊維複合材料のホットプレス成形プロセス

当社工場では、P20 鋼製金型を使用した高度な炭素繊維ホットプレス工程を採用しており、高品質生産のための高効率、高精度、耐久性、コスト効率を保証しています。

“A design is only as honest as its weakest laminate.”

That sentence is half-poetic, half-stern warning. When you specify or build with carbon fiber square tubes, you’re not just choosing a “material with numbers”—you’re entering a quiet dialogue with geometry, fibers, loads, and inevitable imperfections.

In what follows, I’ll try to take you beyond mere descriptions and into deeper terrain: the inward logic of how these tubes “want” to behave, the hidden traps many overlook, and the design mindset that distinguishes safe, elegant parts from those that fail silently.

When you hold a square-section carbon tube in your hand, what you 感じる is the external form—but what matters is the internal fiber architecture, the fiber paths, the transitions across corners, the resin microstructure, and the entropic tendencies of damage.

The square tube is thus a compromise: ease in mounting vs complexity in fiber layout. But a well-designed square composite can outshine many alternatives.

Think of each ply—oriented at 0°, ±45°, 90°, and hybrid angles—as a musical instrument. The 0° plies carry axial tension and bending loads; ±45° plies help with shear or torsion; 90° plies (hoop direction) resist local splitting or radial load. Their interactions, adjacency, and interlaminar bonds determine whether the system is robust or brittle.

One modern advance: integrating CNT veils (very thin layers of carbon nanotubes) between plies has been shown to boost Mode-I fracture toughness by ~60%, helping delay delamination. Another: in thin-ply thermoplastic composites, microstructural tuning and precise control over crystallinity can yield ~158 % improvement in transverse strength versus conventional thermoset layups.

So a “tube” is not just a hollow shape—it’s a layered, graded architecture with emergent behavior.

It’s one thing to quote a stiffness or tensile strength; it’s another thing to understand how those values shift with scale, damage, and loading complexity.

Here’s a reference table (with caution: real values depend heavily on material system, fiber quality, layup, and defects):

| 財産 | Typical Value / Range | Significance / Use | Caveats & Notes |

|---|---|---|---|

| Density (ρ) | ~1.5 to 1.8 g/cm³ | Very low compared to metals, enabling weight savings | Variation from voids, resin content, fiber fraction |

| Tensile strength (fiber direction) | 1,500 – 2,500 MPa (laminate lower) | Maximum load in pure tension | In bending or compression, behavior differs |

| Modulus, Eₗ (axial) | 120 – 300 GPa | Governs elastic stiffness in axial or bending loads | Off-axis moduli drop sharply |

| Shear modulus, G | ~4 – 20 GPa | Critical for torsion, shear deformation | Highly dependent on ±45° or bridging plies |

| Glass transition (Tg) | ~100 – 250 °C (resin dependent) | Thermal stability limit | Above Tg, properties degrade |

| Fracture / energy release (Gf) | Material-specific | Key in delamination, crack propagation | Strong size effects; see below |

One often overlooked trap: composites are quasi-brittle. As structures scale up, the nominal strength tends to decrease due to crack or damage propagation mechanisms that don’t scale linearly. In textile composites (e.g. woven fibers), experiments show that nominal strength decreases with specimen size, and that neglecting this “size effect” can cause underpredictions of collapse loads by up to ~70%.

What this means in practical terms: a small coupon test might show impressive strength, but in a long tube, microcrack growth, stress concentrations, and damage spread will reduce effective strength. Design models must include size scaling and fracture energy, not just stress-strain metrics.

Real tubes rarely see purely axial loads. Side load, bending, impact, or lateral compression can trigger complex damage: fiber breakage, microcracking, delamination, buckling. Research on CFRP tubes under lateral loading shows multi-stage damage evolution—initial linear response, onset of delamination microcracks, fiber rupture, and eventual catastrophic collapse.

Further, in impact behavior studies (at room or cryogenic temperatures), carbon/epoxy composite tubes show reduced energy absorption, delamination zones, and loss of stiffness post-impact.

One striking insight: holes (pre-existing defects) in CFRP tubes significantly degrade energy absorption during axial crushing. In one study, adding a 15 mm diameter hole reduced specific energy absorption (SEA) by ~50% in certain positions.

Thus, any hole, notch, or fastening interface must be treated seriously; it isn’t “just a hole” in carbon.

Beyond theory, real tubes carry the scars of their own manufacture: wrinkles, voids, resin-rich zones, fiber misalignment, interlaminar weakness. These imperfections often decide failure, not the “ideal” design.

Before discussing specific fabrication routes, it is worth noting that defect control — rather than nominal material properties — often governs the real-world performance of square carbon fiber tubes.

Closed-mold manufacturing approaches, such as the RTM carbon fiber process, are increasingly used in structural composite components where fiber volume fraction, corner consolidation, and void content must be tightly controlled.

For square-section tubes in particular, RTM enables more uniform resin distribution around sharp corners, improved repeatability between parts, and reduced risk of resin starvation or hidden porosity — all of which directly influence long-term durability and damage tolerance.

Roll-wrapped (prepreg or dry + resin infusion) Many commercial square tubes use roll-wrapped laminates: alternating unidirectional and woven/twill fabrics wrapped around a square mandrel, then cured. DragonPlate’s tubes sandwich the uni-directional core between inner and outer twill to support and protect it. This gives good surface finish, better edge transition support, and cosmetic appeal.

引抜成形 In pultrusion, continuous fibers/resin are pulled through a heated forming die. It offers high throughput and consistency for simple geometries—but less flexibility in fiber orientation.

Braided / multi-directional preforms Advanced research (e.g. “four-way braided thin-walled tubes”) is exploring 3D braided techniques to reduce delamination and improve multi-directional strength.

Hybrid or cold-forging composite bonding New studies look at combining carbon tubes with epoxy composite joints or cold forging techniques to improve dynamic behavior.

In selecting approach, you balance cost, flexibility, quality control, and expected performance.

Let me be blunt: most composite failures stem not from “insufficient strength” in the design, but from 欠陥. Some you can’t see; some you must plan for.

Quality control must include NDT (ultrasound, thermography, X-ray, tap testing), coupon pull tests, and sample destruct tests.

One tip from experienced fabricators: always set aside a “shadow coupon” (a piece made alongside the tube) for destructive testing and correlation. Design your inspection protocols early, not after you build.

Stories stick; numbers fade. Here are real or semi-real narratives that reveal more than formulas.

In the Simons Observatory (a cosmic microwave background telescope), engineers needed struts that are stiff, lightweight, thermally insulating, and survive cryogenic cycles. They used carbon fiber tubes with aluminum end caps. They discovered that the failure point was not the CFRP tube, but rather the interfaces—the end caps and mounting hardware.

They also measured thermal conduction: the carbon tubes passed only <1 mW heat load from 4 K to 1 K, meeting stringent cryogenic performance.

Lesson: your joint design, adhesive selection, thermal mismatches, and interface durability matter just as much as the tube.

A study on carbon composite use in automotive production equipment redesigned a steel gripper in carbon composite and aluminum hybrid form. They achieved ~60% weight reduction, better ergonomics, and robustness without excessive cost.

The twist: many in the shop environment expected heavy collisions, knocks, or misalignment. The design budgeted extra margin around harsh joints, protective covers, and replaceable elements to ensure long life. The “material novelty” was tempered by disciplined engineering.

In lab tests, composite tubes with holes (simulating defects or perforations) dropped energy absorption capabilities dramatically under axial crush. The location of holes was often more influential than their size.

This is a caution: a drilled mounting hole, fastener hole, or wiring pass-through isn’t just a benign cut—it becomes a weak point in crash, impact, or structural resilience.

Here’s a layered way to approach specifying or designing carbon fiber square tubes—not as “pick a size and put it in,” but as a conversation between your constraints and the material’s “desires.”

Begin by listing all loads (primary, secondary, off-nominal). Develop a load hierarchy: which is dominant (bending? torque? axial compression? lateral load?). For each load, ask: “Which fiber direction resists this best?” Map fibers to load paths.

Choose outer size 1つの, thickness t, length ら, but anticipate adding local stiffeners, ply drops, or patches. Don’t commit to uniform thickness blindly—constrain ends and joints more heavily.

Design a basic stacking sequence (e.g. [0/±45/0] symmetric), but add buffer plies or hybrid plies near edges or joints. Transition gradually (e.g. 10°, 20° layers) to reduce sudden stiffness jumps and delamination risk.

This is often where things fail:

Don’t rely purely on classical beam theory. Use FEA models with cohesive zone modeling, fracture energy, and size effect scaling. Include potential delamination, microcracks, and progressive failure models.

Prototype early. Embed strain gauges, acoustic emission sensors, or FBGs (fiber Bragg grating sensors) to detect damage. Test under real environments (temperature, humidity, impact). Let your prototypes “talk back.”

Plan inspection intervals, allowable damage thresholds (e.g. allowable delamination length), and design for repair (patchability, ease of sanding, localized reinforcement). Include protective surfaces (UV coatings, edge guards) to reduce hidden damage initiation.

If you publish or market this, here’s how to make it richer than your competitors:

Embed your own data / test curves Don’t just quote generic numbers. Use your coupon test, bending vs load graphs, failure images, strain maps, FEA deflection curves.

Show the human side Include anecdotes of failures, surprises, redesigns. Show how you (or another engineer) iterated from early prototypes to robust final parts.

Layer the narrative Don’t present theory first, then application. Instead, interleave “why this matters” stories: “In one project, we thought the tube was safe, until a tiny ding caused delamination that killed performance.”

Offer design “recipes” with caveats E.g. “If you expect about 10 N·m torsion, start with a ±45° ply thickness of at least 10% of total, but boost it near edges by +20%.”

Be honest about risk & uncertainty Say: “In fatigue, we recommend ×2 safety margin; in high-temperature use, derate modulus by 20%; in impacts, inspect after any knock.”

Include illustrative visuals & annotated figures

Preview future trends & R&D frontiers Talk about the promise of thin-ply thermoplastics, embedded sensing (FBG, carbon fiber self-sensing), CNT interlayers, automated layup robotics, composite-metal hybrids、 そして リサイクル炭素繊維 (e.g. MCAM’s efforts at closing the loop in carbon recycling).

Include a “design decision map” A flowchart: start → define loads → pick size → choose layup → choose manufacturing → prototype → test → revise → production. Annotate decision points and failure modes.

Here’s a possible structure you can fill. Use this as a blueprint:

はじめに

What Lives Inside the Tube

Numbers, Limits, and Scaling

When It Breaks — and What It Tells You

Design Mindset & Strategy

Stories from the Field

Comparative Table: Metal vs CFRP vs Hybrid (Show stiffness per weight, fatigue life, joinability, cost factors, risk)

Trends & Future Horizons

Conclusion: The Promise & the Duty

当社工場では、P20 鋼製金型を使用した高度な炭素繊維ホットプレス工程を採用しており、高品質生産のための高効率、高精度、耐久性、コスト効率を保証しています。

当社の工場では、100 台以上の高温高圧オートクレーブを稼働させ、アルミニウムの型と真空誘導法を使用してカーボン ファイバーを精密に成形しています。高熱と高圧により、強度、安定性、完璧な品質が向上します。

当社の炭素繊維研究センターは、先進的な複合材と Krauss Maffei ファイバーフォームを使用して、新エネルギー、インテリジェンス、軽量設計のイノベーションを推進し、最先端の顧客重視のソリューションを生み出しています。

経験豊富な炭素繊維製品工場からのよくある質問への回答は次のとおりです。

当社は、自動車部品、オートバイ部品、航空宇宙部品、船舶アクセサリー、スポーツ用品、産業用途など、幅広い炭素繊維部品を製造しています。

当社では、強度、耐久性、軽量特性を確保するために、主に高品質のプリプレグ炭素繊維とラージトウ炭素繊維強化高性能複合材料を使用しています。

はい、当社の製品は UV 保護仕上げでコーティングされており、耐久性が長持ちし、磨き上げられた外観が維持されます。

はい、弊社の設備は精度と品質を維持しながら大型の炭素繊維部品を生産する能力を備えています。

カーボンファイバー製品を使用する利点は何ですか?

カーボンファイバーは、優れた強度対重量比、耐腐食性、剛性、熱安定性、そして洗練されたモダンな外観を備えています。

当社は、軽量で高性能なカーボンファイバー部品を中心に、自動車、オートバイ、航空宇宙、海洋、医療、スポーツ、産業の各分野にサービスを提供しています。

はい。 カスタムカーボンファイバー ユニークなデザイン、サイズ、パターンなど、お客様の仕様に合わせたソリューションを提供します。

当社では、オートクレーブ成形、ホットプレス、真空バッグなどの高度な技術を活用し、すべての製品の精度、安定性、品質を確保しています。Hello Elementor テーマで素晴らしい成果を上げている当社では、このテーマがすべての主要テーマでも問題なく動作するように努めています。

当社では、耐久性と高精度を実現するように設計されたアルミニウムと P20 スチールの金型を使用して、複雑で精密なカーボン ファイバー部品を製造しています。

当社の製品は、業界標準を満たすために、寸法精度、材料の完全性、性能テストなどの厳格な品質管理チェックを受けています。