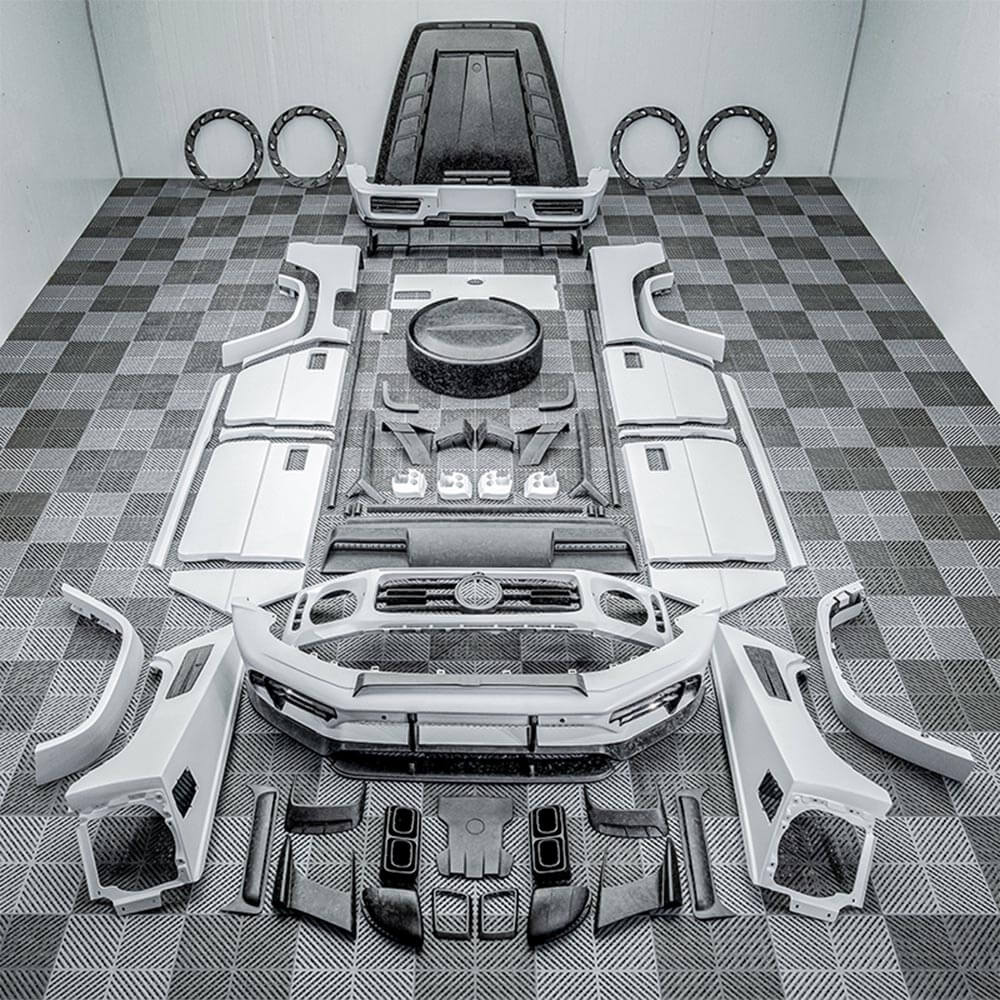

Kit de démarrage en fibre de carbone forgée de première qualité pour les pièces personnalisées haut de gamme

Bienvenue dans le monde de fibre de carbone forgée! Notre kit de démarrage vous aide à faire pièces étonnantes pour les voitures, les avions, le matériel de sport et bien plus encore. Nous sommes un fibre de carbone personnalisée usine de fabrication de produits avec des années d'expérience dans la fabrication des meilleures pièces en carbone.

Pourquoi choisir notre kit ?

- Facile à utiliser - même si vous êtes novice en matière de fibre de carbone

- Matériaux de première qualité - les mêmes que ceux utilisés dans les voitures de luxe

- Support complet - notre équipe vous aide à chaque étape

- Options personnalisées - fabriquer des pièces qui répondent exactement à vos besoins

- Expédition rapide - commencer tout de suite

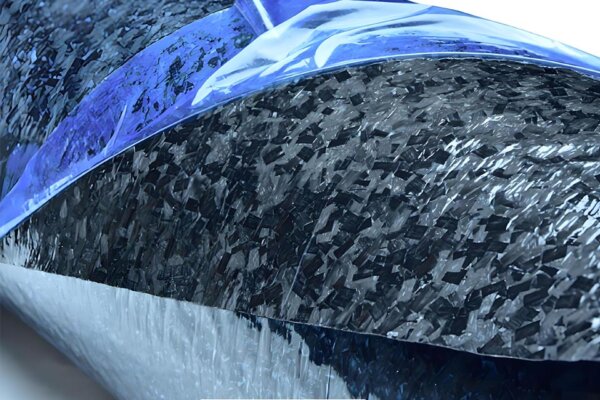

Qu'est-ce que la fibre de carbone forgée et pourquoi est-elle étonnante ?

La fibre de carbone forgée est un nouvelle voie pour fabriquer des pièces en carbone. Il utilise carbone haché mélangé avec résine pour fabriquer des pièces solides et esthétiques. Contrairement aux anciennes fibre de carbone tisséeLe carbone forgé a un aspect marbré que beaucoup de gens aiment.

Le forgé carbone fibre Le processus commence par fibres de carbone hachées qui se mélangent avec les résine époxy. Nous utilisons ensuite chaleur et pression pour réaliser la pièce finale. Cela permet d'obtenir des pièces très résistantes, mais aussi très esthétiques. Nos clients en aérospatial, automobile, et équipement sportif J'adore le fait que les pièces en carbone forgé soient à la fois légères et résistantes. Le motif aléatoire des fibres coupées ensemble donne à chaque pièce un aspect unique qui se démarque.

Kit de développement complet en fibre de carbone forgé

Notre kit de démarrage contient tout ce dont vous avez besoin pour commencer à faire composants forgés en fibre de carbone. Chaque Le kit comprend:

| Article | Quantité | But |

|---|

| Traversée en carbone haché | 500g | Matériau de la fibre principale |

| Résine époxy de première qualité | 1L | Agent liant |

| Durcisseur | 500ml | Active la résine |

| Release Wax | 100g | Pour un retrait facile des pièces |

| Moule de compression (échantillon) | 1 | Pour le façonnage des pièces |

| Manuel d'instruction | 1 | Guide étape par étape |

| Gants de sécurité | 2 paires | Protection |

| Récipients de mélange | 5 | Pour la préparation de la résine |

Le kit de développement en fibre de carbone forgé est conçu pour les nouveaux utilisateurs comme pour les professionnels. Notre système de résine époxy est le même que celui que nous utilisons dans notre usine pour les haute performance parties.

"Ce kit a changé la façon dont nous fabriquons des pièces prototypes. La qualité est incroyable et l'équipe d'assistance nous a aidés à chaque étape." - John M., ingénieur en conception automobile

Comment fabriquer des produits étonnants en fibre de carbone

Fabrication pièces forgées en fibre de carbone est facile avec notre kit. Voici comment procéder :

- Mélanger la résine - Combiner les résine époxy et durcisseur à droite taux de résine

- Préparer le carbone - Obtenez votre carbone haché prêt

- Combiner les matériaux - Mélanger les fibre et résine bien ensemble

- Remplir le moule - Mettez le mélange dans votre moules de compression

- Exercer une pression – Compresser le matériau pour éliminer l'air

- Guérir - Laisser durcir selon notre guide

- Finition - Retirez et polissez votre carbone forgé fini partie Vous pouvez utiliser notre kit avec un Moule imprimé en 3D ou notre moule de compression en deux parties fabriqué de métal. Les deux sont parfaits pour la fabrication de carbone solide parties. Conseils pour de meilleurs résultats :

- Toujours utiliser cire antiadhésive en spray dans vos moules

- Suivre exactement les système de résine instructions de mélange

- Appliquer une pression régulière lorsque en utilisant une compression technique

- Poncer et polir pour une forgé brillant finition

Spécifications techniques de nos matériaux en carbone forgé

Notre véritable fibre de carbone matériels offrent d'excellentes performances mécaniques pour toutes sortes de projets :

- Résistance à la traction : 3500 MPa

- Densité : 1,6 g/cm³

- Résistance à la chaleur : Jusqu'à 180°C

- Contenu en résine : 40% en poids

- Longueur de la fibre : 25 mm remorque hachée

- Temps de séchage : 24 heures à température ambiante ou 4 heures à 80°C Le pièces en fibre de carbone dans notre kit sont coupés à la taille parfaite pour une layup et la meilleure force. Nos résine coulée fonctionne à la fois avec les moulage par compression solide techniques et résine imprimée parties.

Les industries qui aiment notre fibre de carbone forgée

Notre produits en fibre de carbone sont utilisés dans de nombreuses industries de pointe :

- Automobile et moto

- Pièces du tableau de bord

- Panneaux de carrosserie

- Garniture intérieure

- Aérospatial

- Éléments de la cabine

- Pièces non structurelles

- Appareils sur mesure

- Équipements sportifs

- Têtes de club de golf

- Composants de bicyclettes

- Pièces détachées pour raquettes de tennis

- Équipement médical

- Boîtiers d'équipement d'imagerie

- Composants prothétiques

- Aides à la mobilité légères

- Électronique grand public

- étuis de téléphone

- Housses pour ordinateurs portables

- Boîtiers de haut-parleurs

Le processus de moulage nous utilisons des pièces de marque qui ont une belle apparence et qui fonctionnent bien. Quand brins de carbone sont pressés ensemble avec le droit quantité de résineils fabriquent des pièces qui sont meilleures que les pièces ordinaires stratifié carbone.

Pourquoi choisir notre fibre de carbone forgée plutôt que les méthodes traditionnelles ?

| Fonctionnalité | Carbone forgé | Tissage traditionnel | Unidirectionnel |

|---|

| Regarder | Motif en marbre | Tissage régulier | Lignes droites |

| Force | Très élevé | Haut | Le plus élevé dans une direction |

| Facilité d'utilisation | Le plus facile | Moyen | Le plus dur |

| Déchets | Très faible | Moyen | Haut |

| Courbes | Excellent | Limité | Limité |

| Coût | Moyen | Haut | Le plus élevé |

Quand tu acheter fibre de carbone forgée chez nous, vous obtenez des matériaux faciles à travailler. Contrairement à carbone unidirectionnel ou préimprégné notre carbone forgé est plus tolérant pour les formes complexes.

Notre CT12 haché Le système de fibre de carbone peut être placé dans un moule de presque toutes les formes. Il est donc parfait pour fabriquer des pièces complexes qui seraient difficiles à réaliser avec des pièces ordinaires. fibre de carbone tissée.

Avantages de notre procédé de carbone forgé :

- Moins de déchets que les méthodes traditionnelles

- Temps de production plus rapide

- Meilleur pour les formes complexes

- Chaque pièce a un aspect unique

- Plus fort dans plusieurs directions

Nous utilisons le même forgeage Nous utilisons les mêmes techniques que les constructeurs de voitures de luxe, mais nous les mettons au service de vos projets. Notre matériaux composites sont testés pour répondre aux normes les plus strictes.

Histoires de réussite des clients

Notre pièces en fibre de carbone ont aidé de nombreuses entreprises :

"Nous sommes passés au carbone forgé pour nos pièces de moto et les ventes ont augmenté de 30%. Les clients apprécient leur aspect unique. - Mike T., Custom Motorcycle Shop

"Les pièces aérospatiales que nous fabriquons avec ce système ont passé tous nos tests. Les économies de poids sont incroyables." - Sarah L., fournisseur de l'aérospatiale

Notre gamme d'équipements sportifs a été considérablement renforcée par l'ajout des produits suivants fibre de carbone forgée options". - David K., Fabricant d'équipements sportifs

Lorsque vous travaillez avec notre composants forgés en fibre de carboneVous rejoignez des entreprises qui accordent de l'importance à la qualité et à l'innovation. Nos Résine de revêtement XCR donne aux pièces une finition qui dure des années.

Comment commander vos solutions personnalisées en fibre de carbone

Prêt à faire des merveilles pièces forgées en fibre de carbone? Voici comment commander :

- Contacter notre équipe - Parlez-nous de votre projet

- Obtenir un devis personnalisé - Nous créerons une formule adaptée à vos besoins.

- Recevez votre kit – Expédition rapide dans le monde entier

- Commencer à créer - Avec notre soutien total

Pour les projets plus importants, nous proposons des services complets fibre de carbone personnalisée produit fabrication. Notre usine peut fabriquer des pièces de petite ou de très grande taille grâce à notre technologie de pointe. moules de compression et une équipe d'experts.

Options de commande :

- Kits de démarrage pour l'essai et l'apprentissage

- Création de moules sur mesure

- Production en série

- Emballages matériels uniquement

- Formation et soutien

N'attendez pas pour fabriquer du carbone des pièces qui étonneront vos clients. Nos services kit de développement en fibre de carbone forgé est la première étape pour créer des pièces qui se distinguent. Contactez-nous dès aujourd'hui pour rejoindre la révolution de la fibre de carbone !

Résumé : Notre carbone forgé de première qualité Kit de démarrage fibre vous offre tout ce dont vous avez besoin pour créer de superbes pièces en carbone de qualité professionnelle. Grâce à son aspect marbré, à sa résistance supérieure et à l'assistance de nos experts, vous fabriquerez en un rien de temps des composants personnalisés étonnants pour l'automobile, l'aérospatiale et bien d'autres secteurs.