炭素繊維をレーザーカットできますか?トップガイド

学ぶ内容

- なぜ レーザー切断 炭素繊維は硬い

- 最高 ツール カーボンファイバーの仕事に

- 私たちの 28歳以上 あなたの問題を解決する

- の 最善の方法 最高級のカーボンファイバーパーツを手に入れる

カーボンファイバー切断の大きな問題

必要ですか カーボンファイバー部品? あなたは 悪いカット? 多くのショップではカーボンファイバーを正しく切断できません。そのため、すぐに壊れてしまう不良部品が作られます。

カーボンファイバー 非常に強力ですが、切るのは非常に困難です。切ろうとすると、次のような悪いことが起こります。

- ほつれた端 醜いように見える

- 弱点 簡単に壊れる

- 有毒な粉塵 それはあなたを病気にする

- 無駄なお金 故障した部品について

多くの人が使用しようとする 安価なレーザー K40(40W)のように。しかし、これらは 完全に失敗する 1mmの薄いシートでもOK!

なぜこれが悪化するのか

カーボンファイバーの切断が不良だと、次のような問題が発生する可能性があります。

- プロジェクトを停止する 部品が合わないとき

- 製品を美しく見せる 非専門的

- 原因 安全上の問題 部品が壊れたとき

- お金を無駄にする やり直しについて

さらに悪いことに、間違った切り方をすると 有害な煙炭素繊維の粉塵は肺に非常にひどい害を及ぼす可能性があります。

80WのCO₂レーザーを使用すると、うまくいくかもしれませんが、 何度も試みるテストの結果、3mm シートでは 60% しか動作しないことがわかりました。

解決策:当社の専門的な炭素繊維製造

と 28歳以上 カーボンファイバー部品の製造でこれらの問題を解決しました。当社の中国工場では 最高の技術 完璧なカーボンファイバー部品を作るために カスタム 350Z フロントフードフィット感の向上、軽量化、冷却性の向上を目指して設計されています。

私たちの カスタムカーボンファイバー サービスでは以下が提供されます:

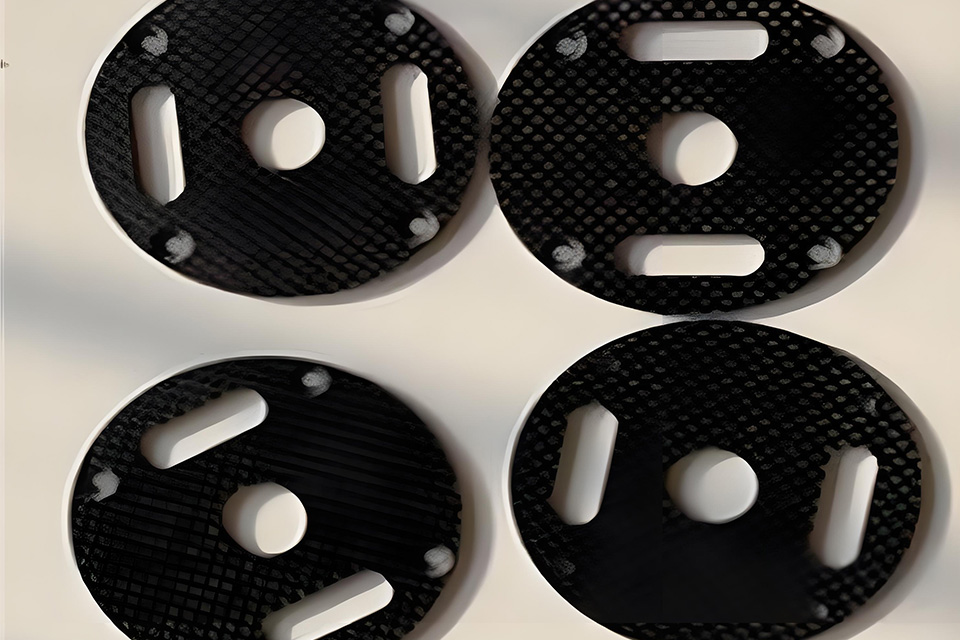

- 完璧なカット ほつれのない

- 強い部分 長持ちする

- 迅速な配達 時間を節約するために

- 適正価格 お金を節約するために

カーボンファイバーを正しくカットする方法

弊社では、お客様の部品を完璧に仕上げるために、以下の最高の方法を採用しています。

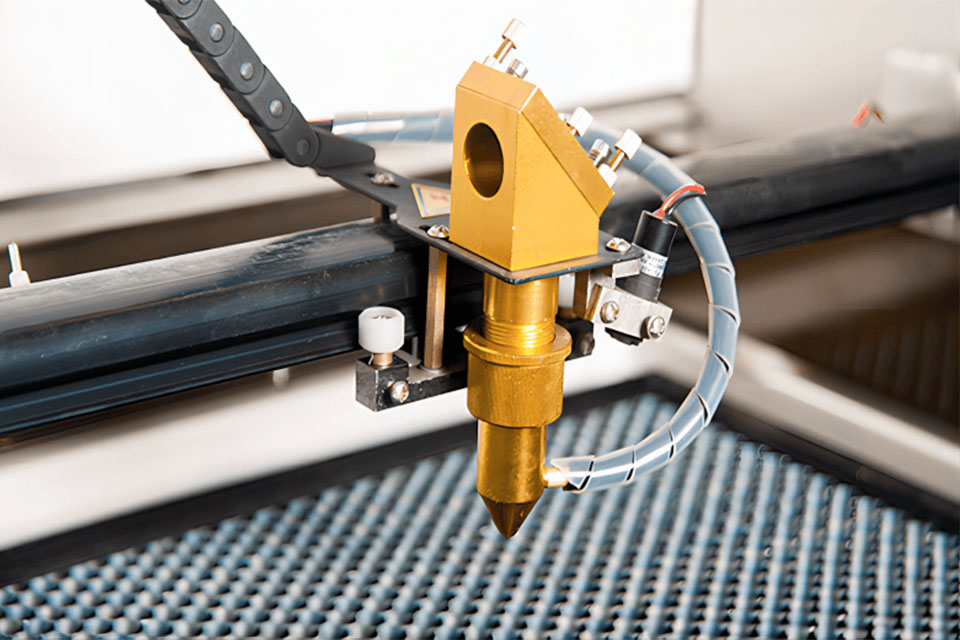

1. 青色レーザー技術

当社の青色レーザーシステムは、 95%成功率 初めての試みで!

なぜそれがより効果的か:

- 作る 滑らかなエッジ 安全に触れることができます

- カット 高精度 (0.1mm以内)

- いいえ 炭素繊維への熱損傷

2. CNCウォータージェット切断

厚いカーボンファイバー(10mm以上)の場合はウォーターカットを使用します。

あなたにとってのメリット:

- 熱によるダメージなし まったく

- カットできる とても厚い ピース

- 作る 完璧なエッジ 毎回

3. 熟練の手による仕上げ

すべての部品は当社の熟練したチームによって検査され、仕上げられます。

これはつまり:

- 鋭い角はありません それはあなたを切り裂く

- 完璧にフィット 最終製品に

- プロフェッショナルな外観 印象に残る

すべてのカーボンファイバー切断方法を比較

| 方法 | 適している | 適さない | 当社の評価 |

|---|---|---|---|

| 青色レーザー | 薄いシート 複雑なデザイン 滑らかなエッジ | 非常に厚いシート | ★★★★★ |

| ウォータージェット | 厚いシート 熱によるダメージなし クリーンカット | 細かい点 コストが高い | ★★★★☆ |

| CO₂レーザー | 高速切断 シンプルな形状 | 高品質のエッジ 厚いシート | ★★☆☆☆ |

| 手工具 | 小さな修正 低コスト | 生産 精度 | ★★☆☆☆ |

実際の成功事例

事例1: ぴったりフィットする自動車部品

自動車メーカーが必要 軽量部品 最初からぴったりでした。以前のメーカーは切り口が悪く、修理が必要でした。

私たちの解決策:

- 完璧なエッジを実現するために青色レーザー(450nm)を使用

- 0.1mmの精度で部品をカット

- 組み立て時間を40%節約

詳細は カーボンファイバーカー ページ!

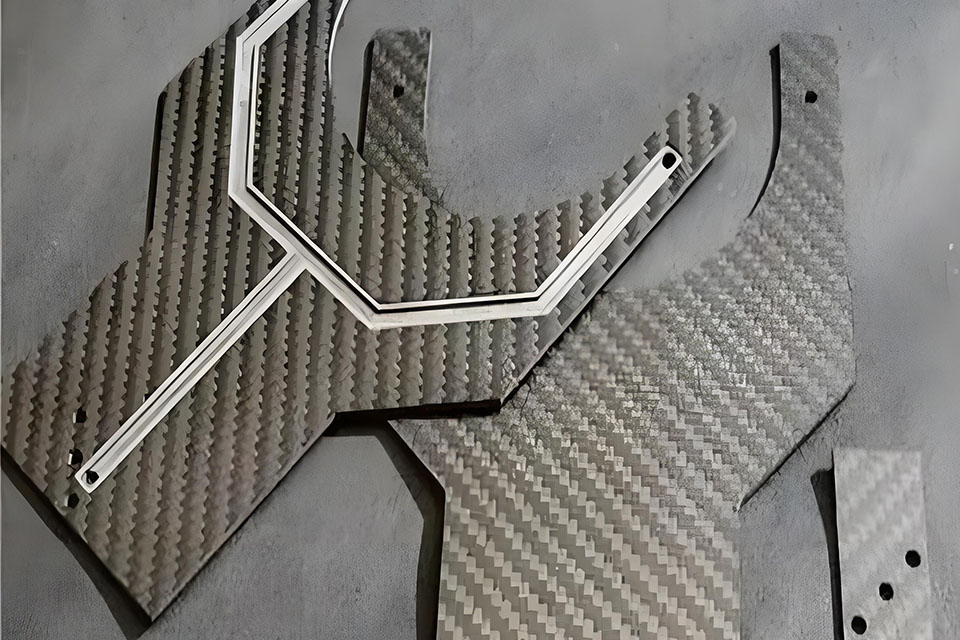

事例2:長持ちするバイク部品

自転車製造業者は、切断不良により弱い部分ができ、部品が壊れてしまいました。

以下の方法で修正しました:

- 厚い部品にウォータージェットを使用する

- 各部品の強度をテストする

- 部品30%の強化

チェックしてください カーボンファイバーバイク 部品をお送りいただければ、私たちがどのようにお手伝いできるかがわかります。

当社の工場を選ぶ理由

- 28歳以上 炭素繊維の製造

- 製造 カスタムサービス

- 最新技術 (青色レーザー、ウォータージェット)

- 完璧な品質 毎回

- 適正価格 工場直送

当社の炭素繊維製造プロセス

ステップ1: デザインヘルプ

弊社は、カーボン ファイバーでより効果的に機能するようにお客様のデザインを修正するお手伝いをします。これにより、コストと時間を節約できます。

ステップ2: 材料の選択

私たちは正しいタイプを選びます カーボンファイバー あなたの仕事のために:

- ツイルカーボンファイバー 見た目を美しくするために

- ウェーブカーボンファイバー 最も強い部品

- 純粋なカーボンファイバー 最軽量

ステップ3: 精密切断

弊社ではお客様の部品に最適な方法を採用しています:

- 青色レーザー 薄くて複雑な部品用

- ウォータージェット 厚くて丈夫な部品用

- CNCマシン 特別なニーズ

ステップ4: 品質チェック

すべての部品は 3 回チェックされます。

- サイズチェック(±0.1mm精度)

- 外観チェック(不良エッジなし)

- 強度チェック(弱点なし)

ステップ5: 迅速な発送

当社はお客様の部品を世界中どこへでも迅速に発送いたします。

当社が取り扱う炭素繊維の種類

炭素繊維シート

- 厚さ: 0.5mm~20mm

- サイズ: 最大2m×4m

- 最適な用途: パネル、カバー、フレーム

カーボンファイバーチューブ

- 直径: 5mm~500mm

- 長さ: 最大3m

- 最適な用途: フレーム、ポール、サポート

カーボンファイバーロッド

- 直径: 0.5mm~50mm

- 長さ: 最大3m

- 最適な用途: サポート、車軸、補強

カスタムシェイプ

- 必要な形は何でも

- あらゆるサイズが可能

- 最適な用途: 特殊部品

当社がサービスを提供する業界

当社のカーボンファイバー部品は、さまざまな分野で使用されています。

- 車とレース – 部品が軽い = 車が速い

- オートバイ – 見た目がかっこよく、より丈夫なパーツ

- ドローンと航空機 – 軽いほど飛行時間が長くなる

- スポーツ用品 – パフォーマンスの向上

- 医療機器 – 強くて軽い

- 海洋 – 錆びない部品

炭素繊維と他の素材

| 材料 | 重さ | 強さ | 料金 | 見て |

|---|---|---|---|---|

| カーボンファイバー | 非常に軽い | 非常に強い | より高い | プレミアム |

| アルミニウム | ライト | 中くらい | 中くらい | 良い |

| 鋼鉄 | 重い | 強い | より低い | 基本 |

| プラスチック | ライト | 弱い | 最低 | 基本 |

カスタムカーボンファイバーパーツの注文方法

ステップ1: デザインを送信する

図面または 3D ファイルをメールで送信してください。

ステップ2: 無料見積もりを取得する

すぐに(通常は当日)価格をお知らせします。

ステップ3: サンプルを承認する

ご確認いただけるようサンプルを作成いたします。

ステップ4: 生産

当社は完璧な品質の部品を製造します。

ステップ5: 配送

部品はすぐに使用できる状態で届きます。

カーボンファイバー切断に関するよくある質問

炭素繊維をレーザーで切断できるものはありますか?

いいえ。K40(40W)のような小型 CO₂ レーザーでは、1mm のカーボン ファイバーも切断できません。当社の青色レーザー システムや高出力ファイバー レーザーのような特殊なレーザーが必要です。

カーボンファイバーの場合、ウォータージェットはレーザーよりも優れていますか?

はい、厚いカーボンファイバー(5mm以上)の場合はウォータージェットの方が適しています。熱による損傷がなく、よりきれいに切断できます。薄い部品の場合は、当社の青色レーザーが最適です。

カーボンファイバーのカット精度はどのくらいですか?

当社のカット精度は±0.1mmです。これは業界標準の±0.5mmよりもはるかに優れています。

カーボンファイバーの切断は有毒ですか?

はい、可能です。当社では、作業員の安全を確保し、きれいな部品を製造するために、すべてのほこりや煙を捕らえる特別なシステムを使用しています。

完璧なカーボンファイバーパーツを今すぐ手に入れましょう

質の悪いカーボンファイバー部品で妥協しないでください。当社の 28 年以上の経験と最高の技術により、常に完璧な部品をお届けします。

訪問 当社のウェブサイト または、カスタムカーボンファイバープロジェクトの無料見積もりを今すぐメールでお送りください。

当社の OEM/ODM 工場が、専門的な製造技術でお客様のカーボン ファイバーの問題を解決します。