カーボンファイバーとはどのようなものか?バイヤーとデザイナー向けガイド

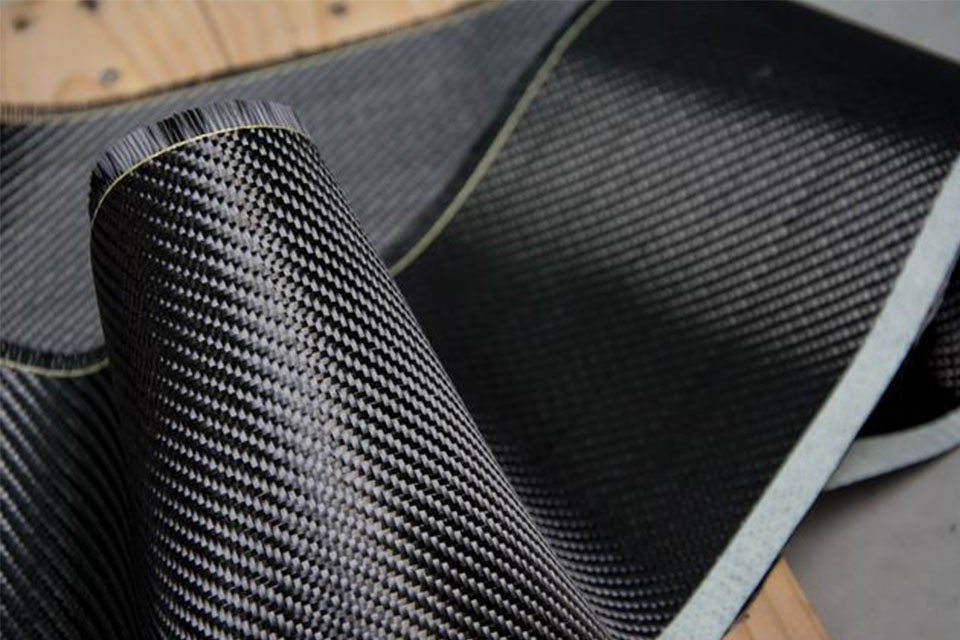

カーボンファイバーの外観:美しさと強さの融合

見えますか 黒 スポーツカーのパーツ?それはカーボンファイバーです。 いいね人々に愛される特別な模様です。

問題: カーボンファイバー製の部品が欲しい人はたくさんいますが、本物のカーボンファイバーがどのようなものか知りません。偽のカーボンファイバーを販売している店もあります。これはお金がかかる上に、うまく機能しません。

なぜこれが重要なのか: 間違ったカーボンファイバーを購入すると、車やバイクの見た目が悪くなります。部品が壊れる可能性もあります。お金の無駄になります。

解決策: 私たちのチーム 中国炭素繊維 は28年以上にわたりカーボンファイバーを製造してきました。本物と偽物の見分け方を熟知しています。見た目が良く、強度に優れた部品を製造しています。

本物のカーボンファイバーの見た目

カーボンファイバーは見た目が特殊です。注目すべき点は次のとおりです。

パターン

本物のカーボンファイバー にはこのようなパターンがある:

- 綾織り: 小さな四角形のように見える

- 平織り: チェッカーボードのように見える

- 一方向: 線が一方向に伸びて滑らかに見える

最も一般的なのは 綾織り小さなダイヤモンドのような模様があります。 カスタムカーボンファイバー ショップではこれらすべてのパターンを作ることができます。

色と輝き

カーボンファイバーはただ黒いだけではありません。次のようなこともできます。

- 深い黒

- グレー

- 均一な色彩(特殊コーティング)

輝きは次のようになります:

- 光沢のある: ガラスのようにとても光沢がある

- マット: 光沢がなく、より平ら

- サテン: 少し光沢があるが、光沢が強すぎない

ほとんど カーボンファイバーカー 光沢仕上げにすることで織り模様が浮き出ます。

業界別炭素繊維

さまざまな車やバイクが、それぞれ独自の方法でカーボンファイバーを使用しています。

| 業界 | コモンルック | 人気の仕上げ | 私たちの経験 |

|---|---|---|---|

| 高級車 | 綾織り | 高光沢 | 1000以上の部品を製造 |

| レースカー | 平織り | マットまたは光沢 | 500以上のレーシングパーツ |

| オートバイ | ツイルまたは無地 | 光沢のあるクリアコート | 2000+ オートバイ部品 |

| ドローン | 一方向 | マット仕上げ | 300以上のカスタムドローンフレーム |

| スポーツ用品 | 綾織り | サテン仕上げ | 750以上のカスタムパーツ |

偽造カーボンファイバーの問題点

問題: 偽のカーボンファイバーが市場に溢れています。ただのステッカーやペイントです。

それがあなたにどんな害を与えるか:

- 暑い日差しで剥がれてしまう

- 濡れると泡立つ

- 重量を減らすのではなく、増やす

- 簡単に壊れる

- 近くで見ると安っぽく見える

本物のカーボンファイバーの見分け方

本物のカーボンファイバーの特徴:

- 深さ: よく見ると層が見えます

- クールな感触: 暑い日差しの中でも触ると涼しい

- 音: タップすると、中空ではなく、しっかりとした音が聞こえます

- 重さ: サイズの割にとても軽い

- 価格: あまり安くない(安すぎる場合は偽物です)

2025年の炭素繊維のトレンド

炭素繊維の世界は急速に変化しています。2025 年までに次のような変化が見られるでしょう。

- カーボンファイバー部品を搭載した車が増える

- リサイクル炭素繊維のさらなる利用

- コストを抑えた新しい製造方法

- より多くの色とパターン

- 見た目を変えるスマートカーボンファイバー

28 年以上のスキルを持つメーカーとして、私たちはこうしたトレンドを常に先取りしています。

当社のOEM/ODMカーボンファイバーを選ぶ理由

問題: 優れたカーボンファイバーメーカーを見つけるのは難しいです。多くのショップは技術がなかったり、安価な材料を使っていたりします。

なぜそれが重要なのか: 質の悪いカーボンファイバーは見た目も悪く、フィット感も悪く、すぐに壊れてしまいます。

私たちのソリューション: 当社は 28 年以上にわたりカーボン ファイバー部品を製造してきました。当社は次のような部品を製造しています:

- 見た目も完璧

- ぴったりフィット

- 何年も持続する

- 適切なコスト

当社の炭素繊維プロセス

- あなたと話します: 必要なものを学びます

- 計画を立てる: 部分を描きます

- サンプルを作成する: 見た目はこんな感じ

- 部品を作る: 最良の方法を採用しています

- すべての部分をチェックする: 当店では不良品は一切出しません

- 迅速に発送: 部品を時間通りに受け取る

当社が製造する炭素繊維製品の種類

当社は様々なタイプのカーボンファイバー製品を製造しています。

車用

- フード

- ネタバレ

- ダッシュボード

- サイドミラー

- 内装トリム

オートバイ用

- ガスタンク

- フェアリング

- フェンダー

- チェーンガード

- フロントガラス

スポーツ用

- 自転車フレーム

- ヘルメット

- ゴルフクラブパーツ

- テニスラケット

- スキーポール

ケーススタディ: 実際のカーボンファイバー プロジェクト

高級車パーツ

私たちは高級車ブランドのためにカーボンファイバー製のドアパネルを製作しました。彼らの要望は次の通りです。

- 完璧なツイル織り

- 高光沢仕上げ

- 車のモデルにぴったりフィット

自動車メーカーは見た目が気に入り、さらに 2,000 セットを注文しました。

レーシングバイクパーツ

レースチームは見た目に美しい軽量パーツを必要としていました。私たちは以下を製作しました。

- フェアリング

- 尾部

- フロントフェンダー

彼らはレースに勝利しました。この部品により、バイクの重量が 3 kg 削減されました。

カスタムドローンフレーム

ドローンメーカーは、丈夫でありながら軽量なフレームを必要としていました。私たちは次のようなカーボンファイバーフレームを製造しました。

- 40%は金属よりも軽量でした

- マット仕上げで見た目も素敵でした

- 激しい衝突にも耐えられる

彼らは現在、すべてのドローンに当社のフレームを使用しています。

当社の炭素繊維製造の仕組み

当社は特別な方法でカーボンファイバーを製造しています。

- カーボンファイバークロスを切る: 正確なパターンを使用します

- 樹脂を加える: 繊維をまとめる

- 部品を形作る: お客様の部品に合わせて作られた金型を使用します

- 熱と圧力を加える: これにより部品が強くなります

- トリムと仕上げ: エッジを完璧に仕上げます

- ポリッシュとコート: これで望み通りの輝きが得られます

当社のカーボンファイバーが優れている理由

問題: 多くのカーボンファイバー部品は見た目がおかしいです。織りがまっすぐでなかったり、仕上げに凹凸があったりします。

なぜそれが重要なのか: 高いお金を使うなら、完璧な部品が欲しくなります。

私たちのソリューション: 完璧な外観を実現するために、次の手順に従います。

- 織り目を完璧に整列させます

- 透明樹脂を多めに使用

- 各パーツを手作業で磨きます

- UVカット加工を施しているので見た目もきれいです

本物のカーボンファイバーのコスト

本物のカーボンファイバーは偽物よりも高価です。その理由は次のとおりです。

- 原材料費が高くなる

- 作るには技術が必要です

- 各パーツは手作業が必要です

- ツールは高価です

しかし、支払った金額に見合った品質が得られます。当社の部品:

- 太陽の下で5年以上持続

- 輝きを保つ

- 強くありなさい

- 素晴らしいですね

カスタムカーボンファイバーの注文方法

独自のカーボンファイバー部品が欲しいですか? 方法は次のとおりです:

- 必要なものを教えてください: 写真や絵を送る

- 価格を調べる: 費用はいくらかかるかお伝えします

- サンプルを見る: 確認用に作成します

- 部品を入手する: 製造して出荷します

カーボンファイバーのお手入れ

カーボンファイバーの見た目を良く保つには:

- 石鹸と水で洗う

- 粗い布は使用しないでください

- 屋外の場合はワックスをかけておく

- 直射日光を避けて保管してください

良質のカーボンファイバーは、手入れをすれば何年も長持ちします。

本物のカーボンファイバーの準備はできていますか?

問題: カーボンファイバー製の部品が必要だけど、品質が心配。

リスク間違ったメーカーを選ぶと、部品が不良になり、お金が無駄になり、待ち時間が長くなります。

解決策: 私たちと一緒に働きましょう。当社は 28 年以上にわたりカーボン ファイバーを製造してきました。見た目が素晴らしく、長持ちする部品の作り方を熟知しています。

あなたが本当に望むカーボンファイバーを手に入れるお手伝いをいたします。 中国炭素繊維 または今すぐお電話ください。