탄소섬유 복합소재 핫프레싱 성형 공정

당사 공장에서는 P20 강철 금형을 사용한 첨단 탄소 섬유 핫 프레스 공정을 채택하여 고품질 생산을 위한 높은 효율성, 정밀성, 내구성 및 비용 효율성을 보장합니다.

“A design is only as honest as its weakest laminate.”

That sentence is half-poetic, half-stern warning. When you specify or build with carbon fiber square tubes, you’re not just choosing a “material with numbers”—you’re entering a quiet dialogue with geometry, fibers, loads, and inevitable imperfections.

In what follows, I’ll try to take you beyond mere descriptions and into deeper terrain: the inward logic of how these tubes “want” to behave, the hidden traps many overlook, and the design mindset that distinguishes safe, elegant parts from those that fail silently.

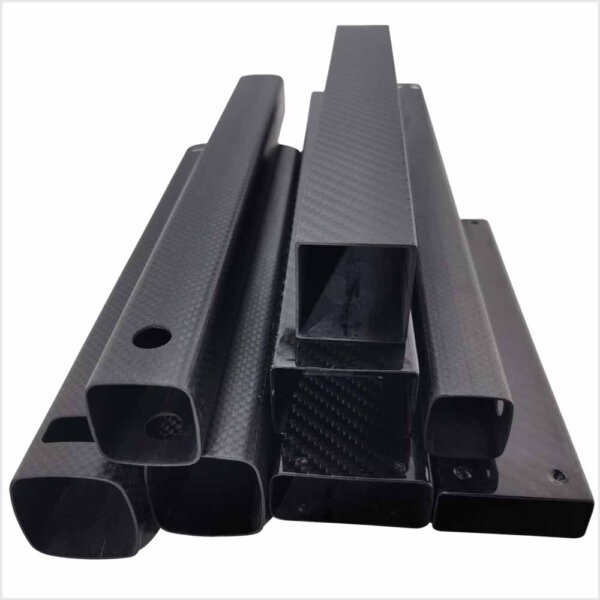

When you hold a square-section carbon tube in your hand, what you 느끼다 is the external form—but what matters is the internal fiber architecture, the fiber paths, the transitions across corners, the resin microstructure, and the entropic tendencies of damage.

The square tube is thus a compromise: ease in mounting vs complexity in fiber layout. But a well-designed square composite can outshine many alternatives.

Think of each ply—oriented at 0°, ±45°, 90°, and hybrid angles—as a musical instrument. The 0° plies carry axial tension and bending loads; ±45° plies help with shear or torsion; 90° plies (hoop direction) resist local splitting or radial load. Their interactions, adjacency, and interlaminar bonds determine whether the system is robust or brittle.

One modern advance: integrating CNT veils (very thin layers of carbon nanotubes) between plies has been shown to boost Mode-I fracture toughness by ~60%, helping delay delamination. Another: in thin-ply thermoplastic composites, microstructural tuning and precise control over crystallinity can yield ~158 % improvement in transverse strength versus conventional thermoset layups.

So a “tube” is not just a hollow shape—it’s a layered, graded architecture with emergent behavior.

It’s one thing to quote a stiffness or tensile strength; it’s another thing to understand how those values shift with scale, damage, and loading complexity.

Here’s a reference table (with caution: real values depend heavily on material system, fiber quality, layup, and defects):

| 재산 | Typical Value / Range | Significance / Use | Caveats & Notes |

|---|---|---|---|

| Density (ρ) | ~1.5 to 1.8 g/cm³ | Very low compared to metals, enabling weight savings | Variation from voids, resin content, fiber fraction |

| Tensile strength (fiber direction) | 1,500 – 2,500 MPa (laminate lower) | Maximum load in pure tension | In bending or compression, behavior differs |

| Modulus, Eₗ (axial) | 120 – 300 GPa | Governs elastic stiffness in axial or bending loads | Off-axis moduli drop sharply |

| Shear modulus, G | ~4 – 20 GPa | Critical for torsion, shear deformation | Highly dependent on ±45° or bridging plies |

| Glass transition (Tg) | ~100 – 250 °C (resin dependent) | Thermal stability limit | Above Tg, properties degrade |

| Fracture / energy release (Gf) | Material-specific | Key in delamination, crack propagation | Strong size effects; see below |

One often overlooked trap: composites are quasi-brittle. As structures scale up, the nominal strength tends to decrease due to crack or damage propagation mechanisms that don’t scale linearly. In textile composites (e.g. woven fibers), experiments show that nominal strength decreases with specimen size, and that neglecting this “size effect” can cause underpredictions of collapse loads by up to ~70%.

What this means in practical terms: a small coupon test might show impressive strength, but in a long tube, microcrack growth, stress concentrations, and damage spread will reduce effective strength. Design models must include size scaling and fracture energy, not just stress-strain metrics.

Real tubes rarely see purely axial loads. Side load, bending, impact, or lateral compression can trigger complex damage: fiber breakage, microcracking, delamination, buckling. Research on CFRP tubes under lateral loading shows multi-stage damage evolution—initial linear response, onset of delamination microcracks, fiber rupture, and eventual catastrophic collapse.

Further, in impact behavior studies (at room or cryogenic temperatures), carbon/epoxy composite tubes show reduced energy absorption, delamination zones, and loss of stiffness post-impact.

One striking insight: holes (pre-existing defects) in CFRP tubes significantly degrade energy absorption during axial crushing. In one study, adding a 15 mm diameter hole reduced specific energy absorption (SEA) by ~50% in certain positions.

Thus, any hole, notch, or fastening interface must be treated seriously; it isn’t “just a hole” in carbon.

Beyond theory, real tubes carry the scars of their own manufacture: wrinkles, voids, resin-rich zones, fiber misalignment, interlaminar weakness. These imperfections often decide failure, not the “ideal” design.

Before discussing specific fabrication routes, it is worth noting that defect control — rather than nominal material properties — often governs the real-world performance of square carbon fiber tubes.

Closed-mold manufacturing approaches, such as the RTM carbon fiber process, are increasingly used in structural composite components where fiber volume fraction, corner consolidation, and void content must be tightly controlled.

For square-section tubes in particular, RTM enables more uniform resin distribution around sharp corners, improved repeatability between parts, and reduced risk of resin starvation or hidden porosity — all of which directly influence long-term durability and damage tolerance.

Roll-wrapped (prepreg or dry + resin infusion) Many commercial square tubes use roll-wrapped laminates: alternating unidirectional and woven/twill fabrics wrapped around a square mandrel, then cured. DragonPlate’s tubes sandwich the uni-directional core between inner and outer twill to support and protect it. This gives good surface finish, better edge transition support, and cosmetic appeal.

인발 성형 In pultrusion, continuous fibers/resin are pulled through a heated forming die. It offers high throughput and consistency for simple geometries—but less flexibility in fiber orientation.

Braided / multi-directional preforms Advanced research (e.g. “four-way braided thin-walled tubes”) is exploring 3D braided techniques to reduce delamination and improve multi-directional strength.

Hybrid or cold-forging composite bonding New studies look at combining carbon tubes with epoxy composite joints or cold forging techniques to improve dynamic behavior.

In selecting approach, you balance cost, flexibility, quality control, and expected performance.

Let me be blunt: most composite failures stem not from “insufficient strength” in the design, but from 결함. Some you can’t see; some you must plan for.

Quality control must include NDT (ultrasound, thermography, X-ray, tap testing), coupon pull tests, and sample destruct tests.

One tip from experienced fabricators: always set aside a “shadow coupon” (a piece made alongside the tube) for destructive testing and correlation. Design your inspection protocols early, not after you build.

Stories stick; numbers fade. Here are real or semi-real narratives that reveal more than formulas.

In the Simons Observatory (a cosmic microwave background telescope), engineers needed struts that are stiff, lightweight, thermally insulating, and survive cryogenic cycles. They used carbon fiber tubes with aluminum end caps. They discovered that the failure point was not the CFRP tube, but rather the interfaces—the end caps and mounting hardware.

They also measured thermal conduction: the carbon tubes passed only <1 mW heat load from 4 K to 1 K, meeting stringent cryogenic performance.

Lesson: your joint design, adhesive selection, thermal mismatches, and interface durability matter just as much as the tube.

A study on carbon composite use in automotive production equipment redesigned a steel gripper in carbon composite and aluminum hybrid form. They achieved ~60% weight reduction, better ergonomics, and robustness without excessive cost.

The twist: many in the shop environment expected heavy collisions, knocks, or misalignment. The design budgeted extra margin around harsh joints, protective covers, and replaceable elements to ensure long life. The “material novelty” was tempered by disciplined engineering.

In lab tests, composite tubes with holes (simulating defects or perforations) dropped energy absorption capabilities dramatically under axial crush. The location of holes was often more influential than their size.

This is a caution: a drilled mounting hole, fastener hole, or wiring pass-through isn’t just a benign cut—it becomes a weak point in crash, impact, or structural resilience.

Here’s a layered way to approach specifying or designing carbon fiber square tubes—not as “pick a size and put it in,” but as a conversation between your constraints and the material’s “desires.”

Begin by listing all loads (primary, secondary, off-nominal). Develop a load hierarchy: which is dominant (bending? torque? axial compression? lateral load?). For each load, ask: “Which fiber direction resists this best?” Map fibers to load paths.

Choose outer size 에이, thickness 티, length 엘, but anticipate adding local stiffeners, ply drops, or patches. Don’t commit to uniform thickness blindly—constrain ends and joints more heavily.

Design a basic stacking sequence (e.g. [0/±45/0] symmetric), but add buffer plies or hybrid plies near edges or joints. Transition gradually (e.g. 10°, 20° layers) to reduce sudden stiffness jumps and delamination risk.

This is often where things fail:

Don’t rely purely on classical beam theory. Use FEA models with cohesive zone modeling, fracture energy, and size effect scaling. Include potential delamination, microcracks, and progressive failure models.

Prototype early. Embed strain gauges, acoustic emission sensors, or FBGs (fiber Bragg grating sensors) to detect damage. Test under real environments (temperature, humidity, impact). Let your prototypes “talk back.”

Plan inspection intervals, allowable damage thresholds (e.g. allowable delamination length), and design for repair (patchability, ease of sanding, localized reinforcement). Include protective surfaces (UV coatings, edge guards) to reduce hidden damage initiation.

If you publish or market this, here’s how to make it richer than your competitors:

Embed your own data / test curves Don’t just quote generic numbers. Use your coupon test, bending vs load graphs, failure images, strain maps, FEA deflection curves.

Show the human side Include anecdotes of failures, surprises, redesigns. Show how you (or another engineer) iterated from early prototypes to robust final parts.

Layer the narrative Don’t present theory first, then application. Instead, interleave “why this matters” stories: “In one project, we thought the tube was safe, until a tiny ding caused delamination that killed performance.”

Offer design “recipes” with caveats E.g. “If you expect about 10 N·m torsion, start with a ±45° ply thickness of at least 10% of total, but boost it near edges by +20%.”

Be honest about risk & uncertainty Say: “In fatigue, we recommend ×2 safety margin; in high-temperature use, derate modulus by 20%; in impacts, inspect after any knock.”

Include illustrative visuals & annotated figures

Preview future trends & R&D frontiers Talk about the promise of thin-ply thermoplastics, embedded sensing (FBG, carbon fiber self-sensing), CNT interlayers, automated layup robotics, composite-metal hybrids, 그리고 재활용 탄소 섬유 (e.g. MCAM’s efforts at closing the loop in carbon recycling).

Include a “design decision map” A flowchart: start → define loads → pick size → choose layup → choose manufacturing → prototype → test → revise → production. Annotate decision points and failure modes.

Here’s a possible structure you can fill. Use this as a blueprint:

소개

What Lives Inside the Tube

Numbers, Limits, and Scaling

When It Breaks — and What It Tells You

Design Mindset & Strategy

Stories from the Field

Comparative Table: Metal vs CFRP vs Hybrid (Show stiffness per weight, fatigue life, joinability, cost factors, risk)

Trends & Future Horizons

Conclusion: The Promise & the Duty

당사 공장에서는 P20 강철 금형을 사용한 첨단 탄소 섬유 핫 프레스 공정을 채택하여 고품질 생산을 위한 높은 효율성, 정밀성, 내구성 및 비용 효율성을 보장합니다.

저희 공장은 100개 이상의 고온 압력 오토클레이브를 운영하며, 알루미늄 몰드와 진공 유도를 사용하여 정밀하게 탄소 섬유를 성형합니다. 높은 열과 압력은 강도, 안정성 및 완벽한 품질을 향상시킵니다.

당사의 탄소섬유 연구 센터는 첨단 복합소재와 크라우스 마페이 파이버 폼을 활용해 새로운 에너지, 지능, 경량 설계 분야의 혁신을 주도하여 최첨단 고객 중심 솔루션을 창출합니다.

경험이 풍부한 탄소섬유 제품 공장에서 자주 묻는 질문에 대한 답변을 소개합니다.

당사는 자동차 부품, 오토바이 부품, 항공우주 부품, 선박 액세서리, 스포츠 장비, 산업용 애플리케이션을 포함한 광범위한 탄소 섬유 부품을 생산합니다.

우리는 주로 고품질 프리프레그 탄소 섬유와 대형 견인 탄소 섬유로 강화된 고성능 복합재를 사용하여 강도, 내구성 및 경량 특성을 보장합니다.

네, 당사 제품은 오래 지속되는 내구성을 보장하고 광택 있는 외관을 유지하기 위해 자외선 차단 마감 처리가 되어 있습니다.

네, 당사의 시설과 장비는 정밀도와 품질을 유지하면서 대형 탄소 섬유 부품을 생산할 수 있습니다.

탄소 섬유 제품을 사용하면 어떤 이점이 있나요?

탄소 섬유는 뛰어난 강도 대 중량 비율, 내식성, 강성, 열 안정성, 세련되고 현대적인 외관을 제공합니다.

당사는 가볍고 고성능 탄소 섬유 구성품에 중점을 두고 자동차, 오토바이, 항공우주, 해양, 의료, 스포츠 및 산업 부문을 대상으로 서비스를 제공합니다.

예, 다음을 제공합니다. 커스텀 탄소 섬유 고유한 디자인, 크기, 패턴 등 고객의 사양에 맞춘 솔루션을 제공합니다.

저희는 오토클레이브 성형, 핫 프레싱, 진공 포장과 같은 첨단 기술을 활용하여 모든 제품의 정밀성, 안정성 및 품질을 보장합니다. Hello Elementor 테마와 함께 사용하면 모든 주요 테마에서도 원활하게 작동하도록 하려고 노력합니다.

우리는 내구성과 높은 정확성을 위해 설계된 알루미늄과 P20 강철 금형을 사용하여 복잡하고 정밀한 탄소 섬유 부품을 제작합니다.

당사 제품은 업계 표준을 충족하기 위해 치수 정확도, 재료 무결성, 성능 테스트를 포함한 엄격한 품질 관리 검사를 거칩니다.