How Much Does Carbon Fiber Really Cost for Your Car?

Most real carbon fibre body panels 비용 $400–$2,000 each, bonnets/hoods 실행 $800–$3,500+, roof panels $1,200–$5,000+, 바퀴 $3,000–$10,000/set, 그리고 풀 카본 파이버 바디 또는 모노코크 섀시 can stretch from $30,000 에게 $150,000+. The spread comes from prepreg quality, 오토클레이브 경화, tooling/CNC, labour, 그리고 brand/OEM tolerances.

The Real Cost of Carbon Fiber: Beyond the Price Tag

So, you’re dreaming of that carbon fiber hood for your project car, or maybe just a set of mirror caps to add a touch of motorsport flair. But then you see the price tag, and one question hits you: ‘What am I actually paying for?’

The answer isn’t just in the material itself, but in a journey of aerospace engineering, painstaking craftsmanship, and raw performance obsession. Let’s break down the real costs, so you can invest wisely.

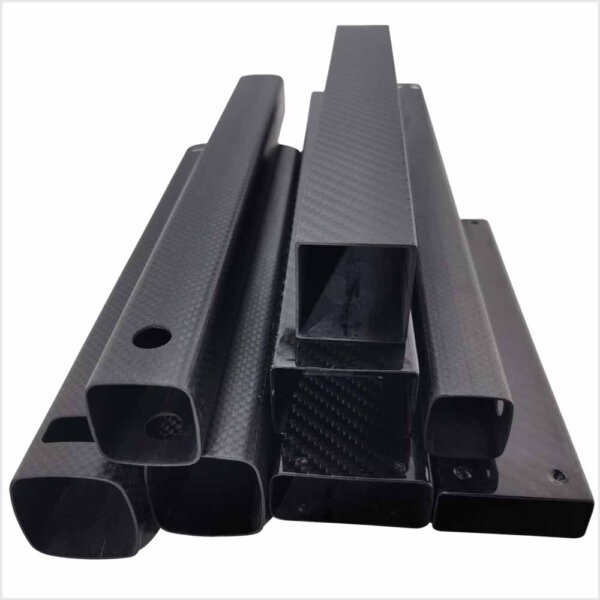

Why Carbon Fiber Isn’t “Just Plastic”

You’ve seen it on Formula One (F1) cars, in 맥라렌 자동차’s MonoCell, on a 람보르기니 forged composite wing, or the roof of a BMW M3 E92. Real 탄소 섬유—the signature material of every true 탄소 복합재 제조업체—is a composite made of thousands of carbon filaments woven into fabric and cured in a 수지 매트릭스.

The payoff is an unbeatable stiffness-to-weight ratio, dramatic 체중 감량, and improved aerodynamic downforce.

The Upside: Unmatched weight savings, extreme rigidity, superior crash absorption, and design flexibility. The Reality: High initial price, specialist repairs, and need for UV-stable clear coats to prevent yellowing.

Quick Cost Table

| 구성 요소 | Typical Price (USD) | 노트 |

|---|---|---|

| 거울 커버 | 150–500 | carbon fibre mirror covers cost; small aesthetic mods |

| Front lip / diffuser | 400–2,000 | carbon fibre diffuser cost car; front splitter |

| 사이드 스커트 | 400–1,600 | carbon fibre side skirts cost; exterior body panel |

| Rear wing / spoiler | 600–3,000 | carbon fibre wing cost for car; spoiler assembly |

| Bonnet / hood | 800–3,500+ | carbon fibre bonnet cost; hood car cost UK; replacement |

| 지붕 패널 | 1,200–5,000+ | carbon fibre roof panel cost; roof conversion cost |

| Doors / bumpers | 1,200–4,500 | carbon fibre car door cost upgrade; bumper |

| Wheels (set) | 3,000–10,000 | carbon fibre wheels cost car; wheel rims |

| 풀바디 키트 | 5,000–20,000+ | carbon fibre kit cost car; body kit UK prices; fitment cost UK |

| Full body panels | 30,000–80,000+ | carbon fibre composite car body cost |

| Monocoque chassis | 60,000–150,000+ | carbon fibre monocoque cost car; race series |

참고: 을 위한 UK buyers, add import tariffs, 해운, 그리고 VAT (imported carbon fibre car parts cost UK; carbon fibre car part shipping cost; kit fitment cost UK). US/EU prices are similar, with higher OEM premiums for 포르쉐 911, Audi RS3 8Y, 그리고 Mercedes-Benz SLR McLaren.

What Really Drives the Price

1) Raw Materials — The Core Ingredient

Let’s start with the core ingredient: the carbon fabric itself. While you can buy DIY rolls online, the real performance comes from 프리프레그—fabrics pre-impregnated with resin by giants like 토레이 또는 Gurit. Think of prepreg as the ‘gourmet ingredient’ that guarantees consistency and strength, but comes at a premium price (prepreg carbon fibre car part cost; carbon fibre cost per kg car part).

- 3K 능직: $25–$40/m²

- Forged composite or unidirectional (UD): $80–$200/m²

- Used widely in 람보르기니, 맥라렌, 그리고 커스텀 탄소 섬유 조작.

2) Manufacturing Process — Where the Magic Happens

- Wet Layup: Budget-friendly but resin-heavy and inconsistent.

- 진공 포장: Stronger and lighter—typical in mid-tier aftermarket.

- 오토클레이브 경화: The gold standard, used by OEMs and our 맞춤형 복합 공장. High temperature and pressure ensure void-free strength, explaining the autoclave carbon fibre car body cost.

3) Tooling, CNC, and Hidden Precision

Before curing, each prepreg layer is hand-laid in moulds designed with CNC 가공 accuracy. Suppliers like Carbo Tech, Dallara Automobili, 그리고 Lotus Sport rely on ISO 9001 standards—similar to our in-house 탄소 복합재 제조업체 workflow.

4) Design Complexity & Finish

에이 flat sheet is easy. A curved vented hood with internal bracing? That’s costly. Premium finishes prevent the dreaded “carbon fibre look yellowish” issue.

5) Brand, Certification & Distribution

OEM brands (e.g., 맥라렌, 포르쉐, Aston Martin, 람보르기니) follow FIA-grade standards. 애프터마켓 producers (like CT Carbon, Reverie Ltd, 그리고 Eurospares) offer savings but demand careful fitment checks.

DIY vs OEM vs Aftermarket

DIY (Proceed Carefully)

A “$500 DIY carbon fibre hood” often ends up costing double once you buy:

- Vacuum pump/bags: $300+

- Mould: $200–$1,000

- Prepreg or epoxy: $400+ Without experience or a clean environment, you’ll get resin-rich, 무거운, 또는 wavy 부분품.

OEM (Factory Grade)

Examples:

- BMW M Performance carbon roof for M3 E92: $3,000–$5,000

- 맥라렌 12C panels or Porsche 911 GT3 aero parts Guaranteed fit, tested durability, and high resale value.

Aftermarket (Smart Savings)

다음과 같은 브랜드 CT Carbon 또는 Reverie Ltd deliver solid results at half the OEM cost—as long as the process is true prepreg autoclave. Great for aesthetic upgrades on 탄소섬유 자동차 or custom builds.

Material Comparison Table

| 특징 | 탄소섬유 | 알루미늄 | 강철 | 유리섬유 |

|---|---|---|---|---|

| 무게 | Lightest (best weight reduction) | 빛 | 무거운 | 중간 |

| Strength/Stiffness | Extremely high | 높은 | 매우 높음 | 보통 |

| 수리 가능성 | 어려움 | 쉬운 | 쉬운 | 보통 |

| 비용 | 높은 | 중간 | 낮은 | 낮은 |

| Visual appeal | Premium weave | Metallic | 산업 | Paintable |

| Use case | Performance, racing | 양산 | 구조 | Budget builds |

ROI: In racing and high-performance use, 탄소 섬유 wins. For daily driving, aluminium or fiberglass may suffice.

Is Carbon Fiber Worth It for Your Car?

- Track Cars: Absolutely. Every kilogram counts.

- Supercars/Luxury Sedans: Yes — keeps value, enhances character.

- Daily Drivers: Probably not — opt for 거울 커버, 내부 트림, 또는 steering wheel accents.

Repair & Maintenance

- Repair costs: $400–$2,000 depending on crack type.

- Yellowing prevention: UV-stable clear coat and regular detailing.

- Wrap vs Real: carbon fibre wrap vs genuine cost — wraps are 1/10 the price but purely aesthetic.

The Brands That Define the Market

- The Benchmark Setters: 맥라렌 (MonoCell), 람보르기니 (forged composites), 포르쉐, 그리고 Aston Martin. You’re paying for peak R&D and performance.

- Engineering Partners: Carbo Tech, Gurit, Dallara Automobili – the hidden masters behind many race and supercar chassis.

- Quality Aftermarket: CT Carbon, Reverie Ltd – offering proven performance at a more accessible price point.

자주 묻는 질문

How much does carbon fibre cost per kg for car parts? Raw fibre: $12–$25/kg, prepreg: $80–$120/kg, finished parts: $400–$1,000/kg.

Why is a carbon fibre bonnet more expensive than aluminium? Because of 프리프레그 소재, autoclave energy, CNC tooling, 그리고 hand layup labour.

What’s the OEM vs aftermarket price gap? OEM is typically 1.5–3× more, but guarantees fitment and warranty.

Is forged composite cheaper? Yes, up to 40% cheaper to mass-produce, but less fibre alignment and gloss uniformity.

UK fitment & shipping costs? Expect to add import tariffs, 보험, 그리고 VAT.

Sources, Review & Author

Based on verified pricing from 토레이, Gurit, Carbo Tech, and in-house production data from our 맞춤형 복합 공장. Technical review by composite engineers, updated Nov 2025.

Disclaimer: Prices vary by material grade, region, and certification standards.