탄소섬유는 내열성이 있나요? 제품에 중요한 이유

문제: 열을 견딜 수 있는 재료 찾기

당신은 얻을 수있는 것들을 만드십니까? 더운? 너무 뜨거워지면 많은 부품이 고장납니다. 이것은 큰 문제.

자동차 부품, 자전거 부품, 비행기 부품은 보관해야 합니다. 강한 뜨거울 때도. 일반 플라스틱은 녹습니다. 금속은 너무 무거워집니다. 무엇을 사용할 수 있습니까?

다음과 같은 재료가 필요합니다.

- 숙박 강한 더울 때

- ~이다 빛

- 하지 않습니다 부서지다

- 외모 좋은

열 손상에 대한 고통스러운 진실

열로 인해 부품이 고장나는 경우, 나쁜 일이 일어난다:

- 자동차 부품은 녹다

- 자전거 부품을 얻을 수 있습니다 부드러운

- 비행기 부품은 부서지다

- 당신의 좋은 부분이 됩니다 쓰레기

- 당신은 잃습니다 돈

- 사람들은 얻을 수 있습니다 아프다

매년 회사들은 손실을 입습니다. 수백만 달러 열 손상으로부터. 귀사의 제품에는 이러한 문제를 막기 위해 더 나은 소재가 필요합니다.

솔루션: SCOMP의 내열 탄소 섬유

우리는 만든다 탄소섬유 부품 열을 견딜 수 있는! 28년 이상 탄소 섬유를 만들어 온 우리는 내구성이 뛰어난 부품을 만드는 방법을 알고 있습니다. 강한 더울 때에도요.

우리의 커스텀 탄소 섬유 제품은 당신이 더 나은 것을 만드는 데 도움이 될 수 있습니다. 우리는 OEM/ODM 서비스를 완벽하게 제공하는 중국 최고의 공장입니다.

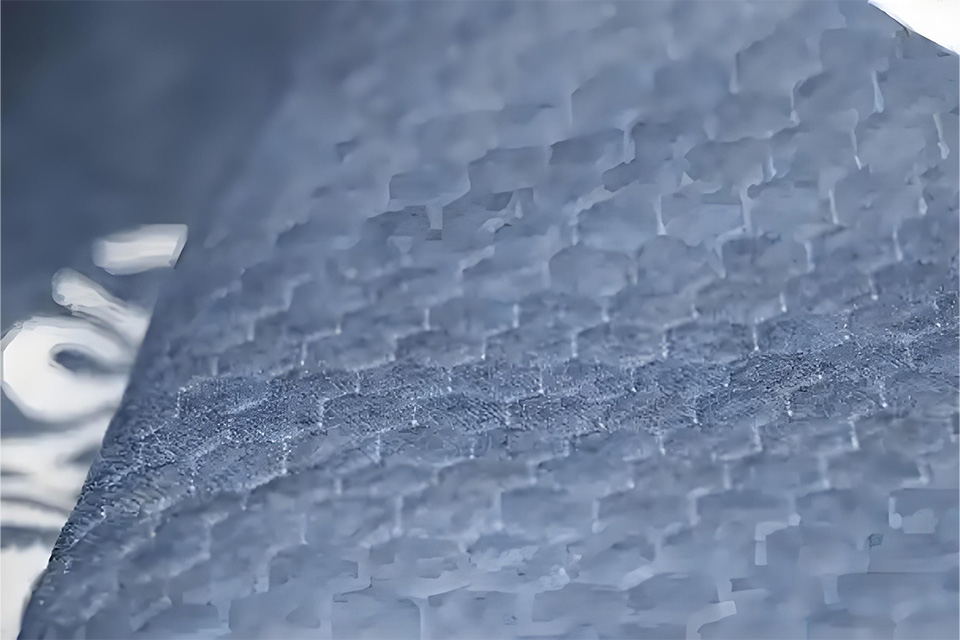

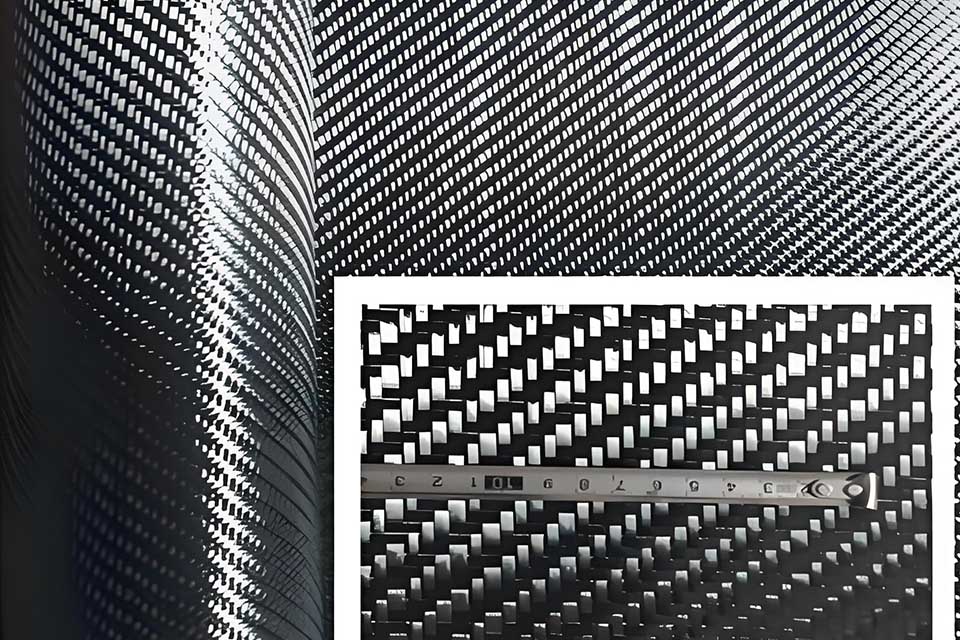

탄소섬유란?

탄소 섬유는 모두 서로 붙어 있는 얇은 탄소 끈입니다. 그것은:

- 더 강하다 강철보다

- 거룻배 금속보다

- 내열성

- 멋지네요

탄소섬유는 PAN(폴리아크릴로니트릴)이라는 특수한 물질로 만들어집니다. 먼저, 우리는 석유와 석탄에서 PAN을 꺼냅니다. 그런 다음 탄소섬유로 만듭니다.

탄소 섬유의 내열성은 얼마나 되나요?

순수 탄소 섬유는 매우 높은 열. 매우 내열성이 뛰어납니다!

But most carbon fiber you use comes in a mix called CFRP (Carbon Fiber Reinforced Plastic). The heat it can take depends on what we mix with the carbon fiber.

다양한 유형이 얼마나 많은 열을 견딜 수 있는지 살펴보겠습니다.

| 탄소섬유의 종류 | 얼마나 뜨거워질 수 있을까 | 무슨 일이 일어나는가 |

|---|---|---|

| 순수 탄소 섬유 | 2000°C 이상 | 강력하게 유지됩니다 |

| 에폭시 탄소 섬유 | 약 100°C | 부드러워진다 |

| 탄소 세라믹 매트릭스 | 1500°C 이상 | 비행기에 좋다 |

| 니켈이 포함된 탄소 섬유 | 300~500°C | 불에 좋다 |

사람들이 우리의 탄소 섬유 제품을 선택하는 이유

우리의 탄소섬유 제품이 더 나은 이유는 다음과 같습니다.

- 전문 지식: 28년 이상 탄소섬유 제작

- 주문 제작: 우리는 당신이 필요로 하는 것을 만듭니다

- 내열성: 부품은 뜨거울 때도 튼튼합니다.

- 풀서비스: 아이디어부터 완성까지

- 품질 우선: 우리는 모든 것을 테스트합니다

더운 곳의 탄소 섬유

탄소 섬유는 많은 더운 곳에서 효과적입니다.

1. 자동차 부품

자동차는 뜨거워집니다! 엔진은 100°C 이상까지 올라갈 수 있습니다. 탄소섬유 자동차 부품은 뜨거운 엔진 근처에서도 견고함을 유지합니다.

- 엔진 커버

- 후드 통풍구

- 배기 실드

- 브레이크 냉각 덕트

모든 부품은 높은 열에 노출되지만, 우리의 탄소 섬유는 그것을 잘 처리합니다!

2. 오토바이 부품

자전거는 열을 멀리할 공간이 훨씬 적습니다. 탄소섬유 오토바이 부품은 뜨거운 엔진 바로 옆에서 열을 받을 수 있습니다.

- 배기 가드

- 방열판

- 엔진 커버

- 가스 탱크 커버

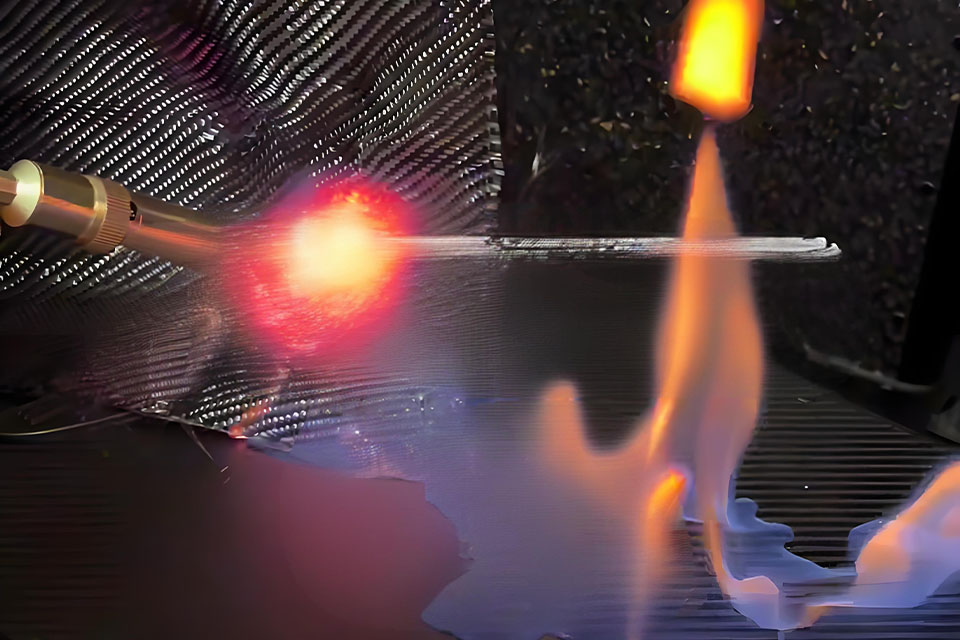

3. 방화장비

일부 탄소 섬유는 소방 장비에도 들어갑니다! 특수 코팅을 통해 탄소 섬유는 소방관을 안전하게 보호합니다.

4. 비행기 부품

비행기는 큰 열 변화를 겪습니다. 하늘 높이 -50°C에서 더운 날 100°C+까지. 저희 탄소 섬유는 모든 온도에서 튼튼합니다.

내열 탄소섬유를 만드는 방법

당사의 공정은 귀하의 부품이 열을 견딜 수 있도록 보장합니다.

- 우리는 올바른 유형의 탄소 섬유를 선택합니다

- 우리는 더 많은 열을 흡수하는 더 나은 수지를 사용합니다

- 우리는 테스트하고, 테스트하고, 테스트합니다!

- 추가 열을 위해 특수 코팅을 추가할 수 있습니다.

대부분의 탄소섬유가 열 한계를 갖는 이유

대부분의 탄소 섬유 부품은 약 100°C에서 부드러워지는 에폭시를 사용합니다. 하지만 그게 전부는 아닙니다!

그만큼 실제 문제 이다:

- 일반 에폭시는 100°C에서만 부드러워집니다.

- 부드러워지면 부품이 구부러지거나 부러질 수 있습니다.

- 대부분의 매장에서는 기본 에폭시만 사용합니다.

- 그들은 열을 더 좋게 만드는 방법을 모릅니다

열 문제를 해결하는 방법

SCOMP에서는:

- 사용 더 나은 수지 더 많은 열이 필요해요

- 만들다 특별한 믹스 핫스팟을 위해

- 적용하다 방열판 필요한 곳에

- 설계 부품 열을 멀리 옮기다

- 테스트 진짜 더위 귀하의 제품이 보일 것 같은데요

뜨거운 어플리케이션을 위한 맞춤형 탄소 섬유

필요 커스텀 탄소 섬유 열을 견딜 수 있는 부품? 우리는 모든 것을 합니다:

- 사용자 정의 모양: 원하는 모든 모양

- 사용자 정의 크기: 크거나 작거나

- 사용자 정의 열 사양: 얼마나 더운지 알려주세요

- 맞춤형 룩: 광택, 무광, 색상

- 사용자 정의 강도: 바로 당신에게 필요한 것

탄소섬유 시장이 빠르게 성장하고 있습니다

매년 더 많은 사람들이 탄소섬유를 원합니다. 전문가들은 2033년까지 탄소섬유 시장이 가치가 있을 것이라고 말합니다. $371억5천만원!

왜? 더운 곳과 힘든 작업에 매우 잘 작동하기 때문입니다.

실제 사례 연구: 핫 엔진 부품

어떤 자동차 제조업체에서 문제를 가지고 우리에게 왔습니다.

- 그들의 플라스틱 엔진 커버는 녹는

- 금속이 너무 무거운

- 그들은 다음과 같은 것이 필요했습니다. 시원한

우리는 다음과 같은 탄소 섬유 커버를 만들었습니다.

- 200°C까지 가열합니다.

- 70%는 금속보다 가볍습니까?

- 정말 멋져 보여요

- 녹거나 변형되지 마세요

이제 그들의 차는 더 시원하게 달리고 더 보기 좋아졌어요!

특수한 종류의 내열 탄소섬유

우리는 다양한 열 요구 사항에 맞게 여러 유형을 생산합니다.

1. 세라믹 매트릭스 탄소 섬유

이 엄청 튼튼한 물질은 1500°C를 견딜 수 있어요! 다음에서 사용:

- 로켓 부품

- 제트 엔진

- 경주용 자동차 부품

- 매우 뜨거운 기계

2. 고온 에폭시 탄소 섬유

당사의 특수 에폭시 혼합물은 더 많은 열을 필요로 합니다.

- 200°C까지 좋음

- 더울 때는 딱딱함을 유지합니다

- 이국적인 유형보다 비용이 저렴합니다

- 대부분의 뜨거운 자동차 및 자전거 부품에 사용 가능

3. 니켈코팅 탄소섬유

니켈을 추가하면 더 많은 열이 발생할 수 있습니다.

- 500°C까지 좋음

- 열이 통과하는 것을 차단합니다

- 방화장비에 도움이 됩니다

- 은색이고 멋지네요

내열성 탄소 섬유가 필요한지 확인하는 방법

다음과 같은 경우 부품에 내열성 탄소 섬유가 필요합니다.

- 80°C보다 더 뜨거워집니다

- 엔진이나 배기가스 근처에 있습니다

- 그들은 오랫동안 햇볕에 앉아 있습니다

- 일반 플라스틱은 거기서 녹습니다

- 금속이 너무 뜨거워서 만질 수 없어요

내열성 탄소 섬유에 SCOMP를 선택하는 이유

- 28년 이상의 경험: 우리는 무엇이 효과적인지 알고 있습니다

- 전체 테스트: 우리는 그것이 열을 흡수하도록 합니다

- OEM/ODM 전문가: 당신을 위해 만들어드립니다

- 품질 우선: 모든 부분이 완벽해요

- 정시 납품: 필요할 때 부품을 받으세요

내열 부품을 얻기 위한 단계별 프로세스

- 귀하의 요구 사항을 알려주세요: 얼마나 더워요? 어떤 모양이에요?

- 우리는 계획을 세운다: 저희 전문가가 디자인합니다

- 첫 번째 샘플: 샘플을 보고 테스트해보세요

- 생산: 우리는 귀하의 전체 주문을 처리합니다

- 테스트: 우리는 그것이 완벽하도록 보장합니다

- 해운: 안전하게 집까지 배달해드립니다

오늘부터 더 나은 내열 부품 제작을 시작하세요

열이 제품을 망치지 않도록 하세요. 저희의 탄소 섬유는 열을 견뎌내고 제품을 더 좋게 만들어줍니다!

- 거룻배 지금 사용하는 것보다

- 더 강하다 더울 때에도

- 더 좋아 보인다 플라스틱이나 금속보다

- 더 오래 지속됩니다 더운 곳에서

내열성 탄소 섬유 부품 제작을 시작하려면 지금 [email protected]로 이메일을 보내세요.

비교: 탄소섬유 대 열에 대한 다른 재료

| 재료 | 무게 | 열 제한 | 힘 | 바라보다 | 비용 |

|---|---|---|---|---|---|

| 탄소섬유 | 매우 가벼움 | 100-2000°C* | 매우 강함 | 놀라운 | 더 높은 |

| 플라스틱 | 빛 | 80~150도 | 중간 | 좋아요 | 낮은 |

| 알류미늄 | 중간 | 400~600°C | 강한 | 좋은 | 중간 |

| 강철 | 무거운 | 800~1000℃ | 매우 강함 | 좋아요 | 중간 |

| 티탄 | 중간 | 1600°C | 매우 강함 | 좋은 | 매우 높음 |

*사용되는 탄소섬유 및 수지의 종류에 따라 다릅니다.

내열 탄소 섬유에 대한 FAQ

탄소 섬유는 불이 붙을 수 있나요?

순수 탄소섬유는 불타기 매우 어렵습니다. 하지만 우리가 섞은 수지는 고온에서 타버릴 수 있습니다. 우리는 그것을 더 안전하게 만들기 위해 방화 물질을 추가할 수 있습니다. [^8]

내 부품에 내열성 탄소 섬유가 필요한지 어떻게 알 수 있나요?

온도가 80°C 이상 올라가거나 엔진과 같이 뜨거운 물체 근처에 있을 경우 내열형 제품이 필요합니다.

내열성 탄소 섬유는 더 비쌉니까?

네, 일반 탄소 섬유보다 조금 더 많습니다. 하지만 열로 인해 계속 부서지는 부품보다는 훨씬 적습니다!

내열성 탄소 섬유는 얼마나 오래 지속됩니까?

우리의 특수 수지는 더운 곳에서도 10년 이상 지속됩니다.

모든 모양을 내열성으로 만들 수 있나요?

네! 원하는 어떤 모양이든 내열성으로 만들어 드릴 수 있습니다.

내열 탄소 섬유에 대한 필요 사항은 저희에게 문의하세요

열을 견딜 수 있는 부품을 만들 준비가 되셨나요? 저희가 도와드리겠습니다!

- 이메일: [email protected]

- 핸드폰: +86-136 2619 1009

- 웹사이트: https://chinacarbonfibers.com

열로 인해 제품이 손상되지 않도록 하세요. 더울 때에도 튼튼함을 유지하는 탄소 섬유를 사용하세요!