Kulfiber vs. kevlar: En komplet guide til højtydende materialer

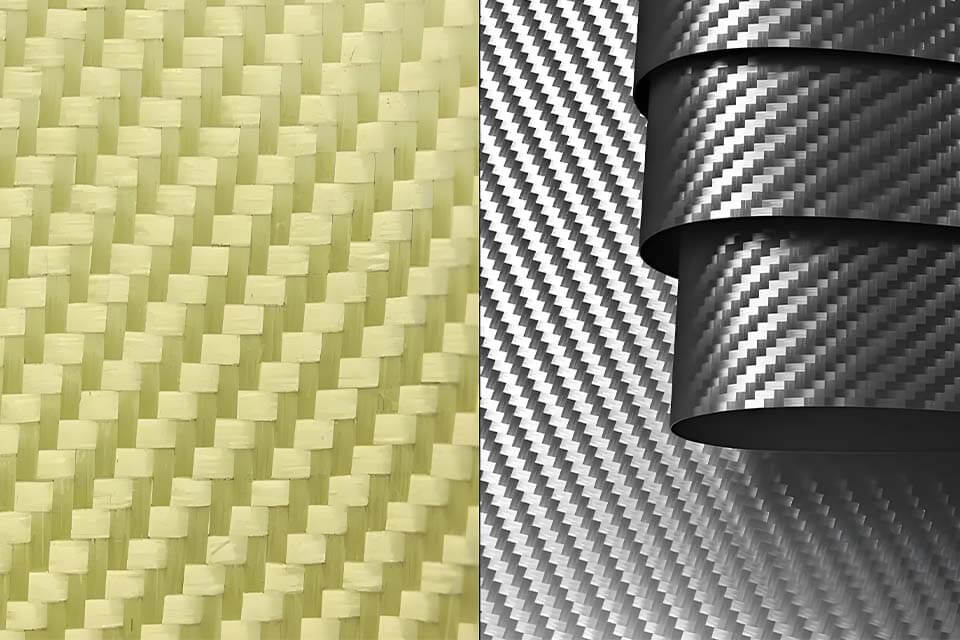

Skal du vælge mellem kulfiber og kevlar? Har du brug for et stærkt, let materiale, men ved ikke, hvilket der er bedst? Når du har brug for stærke materialer, skiller disse to sig ud. Men de fungerer på forskellige måder.

I denne guide ser vi på kulfiber vs. kevlar og hjælper dig med at se, hvad der gør hver enkelt speciel. Vi viser dig, hvad de er lavet af, hvor stærke de er, og hvor de fungerer bedst. Til sidst ved du, hvilken der passer til dine behov.

Oversigt:

- Hvad er kulfiber?

- Hvad er kevlar?

- Kulfiber vs. kevlar: De vigtigste forskelle

- Sammenligning af styrke mellem kulfiber og kevlar

- Hvornår skal man bruge kulfiber?

- Hvornår skal man bruge kevlar?

- Kompositter af kulfiber og kevlar

- Kulfiber vs. kevlar vs. glasfiber

- Pickleball-padler af kulfiber vs. pickleball-padler af kevlar

- Sammenligning af omkostninger: Kulfiber vs. kevlar

- Konklusion: At vælge mellem kulfiber eller kevlar

Hvad er kulfiber?

Kulfiber er en tynd streng lavet af kulstofatomer. Det findes ikke i naturen. Folk fremstiller det i et laboratorium. Hver streng er tyndere end et menneskehår!

Problemet er, at de fleste materialer enten er stærke ELLER lette - ikke begge dele. Når man har brug for noget, der ikke kan bøjes eller gå i stykker, er det ofte for tungt at bære.

Kulfiber løser dette problem. Det er fem gange stærkere end stål men vejer meget mindre. Det er derfor, biler, cykler og fly bruger kulfiberdele.

For at få kulfiber til at fungere, blander vi det med harpiks. Det giver et hårdt, stift materiale, som kaldes kulfiberforstærket polymer (CFRP). Dette kompositmateriale er, hvad de fleste mennesker mener, når de siger "kulfiber".

Vigtige fakta om kulfiber:

- Den er meget stiv og bøjer ikke let.

- Den er ekstremt let

- Den ruster eller korroderer ikke

- Den har et slankt, sort look

- Det bruges i rumfartsindustrien, sportsudstyr og avancerede biler

Hvad er kevlar?

Kevlar er en syntetisk fiber med fantastisk styrke. DuPont skabte det i 1965. Problemet var at finde et materiale, der kunne stoppe kugler, men stadig være let nok til at have på.

Kevlar var den spændende løsning! Det er en særlig type plast, som spindes til fibre og derefter væves til plader eller stof. Materialet er så stærkt, at det kan stoppe en kugle, men alligevel er det let nok til at bære som en vest.

Vigtige fakta om kevlar:

- Det er en syntetisk fiber med høj trækstyrke

- Det er bedst kendt for at blive brugt i skudsikre veste

- Det kan strække sig betydeligt uden at gå i stykker

- Det har fremragende slidstyrke

- Det bruges i beskyttelsestøj, hjelme og sportsudstyr.

Kevlar er også let og fleksibelt, hvilket gør det perfekt til ting, der skal bevæge sig med dig. Når du har brug for et materiale, der kan tåle at blive ramt og blive ved med at fungere, skiller kevlar sig ud.

Kulfiber vs. kevlar: De vigtigste forskelle

Når vi ser på forskellene mellem kulfiber og kevlar, ser vi, at de hver især har unikke styrker. Lad os dele dem op:

| Feature | Kulfiber | Kevlar |

|---|---|---|

| Styrke Type | Høj stivhed, modstår bøjning | Høj trækstyrke, modstår strækning |

| Vægt | Meget let | Lidt tungere end kulfiber |

| Fleksibilitet | Stiv, kan være skør | Fleksibel, kan absorbere stød |

| Modstandsdygtighed over for slag | Dårlig - kan splintre | Fremragende - absorberer energi |

| Se | Sort, blank | Gul eller sort, når den er farvet |

| Koste | Meget dyrt | Dyrt, men mindre end kulfiber |

| Modstandsdygtighed over for slid | Moderat | Fremragende |

| UV-modstand | God | Dårlig (nedbrydes i sollys) |

| Varmemodstand | Fremragende | God |

Den største forskel er, hvordan de håndterer kraft. Kulfiber er stift og bøjer ikke. Kevlar kan bøje og absorbere stød uden at gå i stykker. Derfor er kulfiber fantastisk til rammer og stive dele, mens kevlar fungerer bedst til beskyttelse mod stød.

Sammenligning af styrke mellem kulfiber og kevlar

Når vi taler om styrke, er vi nødt til at gøre os klart, hvilken slags styrke vi mener. Både kulfiber og kevlar er utroligt stærke, men på forskellige måder.

Kulfiber:

- Har utrolig høj stivhed

- Giver fremragende modstandsdygtighed over for bøjning

- Har et højt styrke-til-vægt-forhold

- Fungerer godt under kompression

Kevlar:

- Har en fantastisk trækstyrke (modstandsdygtighed over for at blive trukket fra hinanden)

- Udviser enestående slagfasthed

- Kan absorbere og distribuere energi

- Strækker sig før pause

En kulfiberstreng kan holde til op til 7 gange mere vægt end en ståltråd af samme størrelse. Kevlarfibre har en trækstyrke, der er ca. 5 gange stærkere end stål efter vægt.

Men det er her, det bliver interessant: Kulfiber kan splintres, når det rammes hårdt, mens kevlar absorberer stødet. Det er derfor brugerdefinerede kulfibre kombineres ofte med kevlar for at skabe dele, der er både stive og slagfaste.

Hvornår skal man bruge kulfiber?

Kulfiber brillerer i mange situationer. Dets stivhed og lette vægt gør det perfekt til:

Racer- og sportsudstyr

- Cykelstel

- Tennisketsjere

- Golfkøller

- Padeloverflade i kulfiber (for kraft og kontrol)

Luft- og rumfartskomponenter

- Strukturelle dele af fly

- Satellit komponenter

- Drone-kroppe

Dele til biler

- Kropspaneler

- Indvendig trim

- Kulfiber biler Brug dette materiale til at reducere vægten og øge ydeevnen

Medicinsk udstyr

- Proteser

- Røntgenudstyr

- Kirurgiske instrumenter

Carbon fiber is best when you need something that won’t bend or flex at all. Its stiffness keeps shapes exact, which is why it’s used for precision equipment and advanced load-bearing systems such as carbon fiber robotic exoskeletons, where structural rigidity, low weight, and precise force transfer are critical.

Kulfiberindustrien bliver ved med at vokse, efterhånden som flere ser, hvor nyttigt dette materiale er. Fra kulfiberrør til kulfiberstænger - anvendelsesmulighederne udvides hele tiden.

Hvornår skal man bruge kevlar?

Kevlars fleksibilitet og slagfasthed gør det til det bedste valg til:

Personlig beskyttelse

- Skudsikre veste

- Hjelme på byggepladser

- Brandmandsdragter eller hjelme

- Skærefaste handsker

Sportsudstyr

- Kevlar-padler til pickleball (for holdbarhed og følelse)

- Kanoer og kajakker

- Vandrestøvler

Industrielle anvendelser

- Bremseklodser

- Fiberoptiske kabler

- Dæk

Marineudstyr

- Bådskrog

- Sejl

- Reb

Kevlar bruges også sammen med kulfiber i beskyttelsestøj til motorcyklister. Kevlar absorberer stød, mens kulfiberen giver struktur.

Kevlar er dit foretrukne materiale, når du har brug for noget, der kan klare et slag uden at gå i stykker. Dets evne til at absorbere energi gør det perfekt til beskyttelsesudstyr.

Kompositter af kulfiber og kevlar

Hvorfor vælge mellem kulfiber og kevlar, når man kan bruge begge dele? Kulfiber og kevlar kombineres ofte for at danne en komposit, der udnytter begge materialers styrker.

Problemet Problemet med kun at bruge kulfiber er, at det kan knække under påvirkning. Kevlar alene er måske ikke stiv nok til nogle anvendelser. Når ingeniører blander dem, sker der noget magisk!

Kulfiber giver stivhed og struktur, mens kevlar giver slagfasthed og forhindrer katastrofale svigt. Denne kombination bruges i:

- Motorcykelhjelme

- Karosserier til racerbiler

- Flykomponenter

- High-end sportsudstyr

Hybridmaterialet, der er kendt som kulstof Kevlar giver dig det bedste fra begge verdener. Det er stærkere, mere holdbart og sikrere end begge materialer alene i mange anvendelser.

En typisk kulfiber- og kevlar-komposit kan bruge lag af hvert materiale med harpiks, der binder dem sammen. Det skaber et materiale med unikke fordele, som ingen af komponenterne har i sig selv.

Kulfiber vs. kevlar vs. glasfiber

Når man ser på højtydende materialer, kommer glasfiber ofte på tale sammen med kulfiber og kevlar. Lad os sammenligne alle tre:

| Materiale | Styrke | Vægt | Koste | Holdbarhed |

|---|---|---|---|---|

| Kulfiber | Højeste stivhed | Letteste | Den dyreste | Kan være skør |

| Kevlar | Højeste slagfasthed | Lys | Meget dyrt | Fremragende |

| Glasfiber | God all-around | Den tungeste af de tre | Mest overkommelige | Meget god |

Glasfiber har eksisteret længere end både kulfiber og kevlar. Det er lavet af fine glasfibre, der er vævet sammen og hærdet i harpiks. Selv om det ikke er så stærkt som kulfiber eller kevlar, giver det god ydeevne til en meget lavere pris.

Forskellene mellem kulfiber, kevlar og glasfiber betyder, at de hver især har deres plads:

- Kulfiber fungerer bedst til stive, lette applikationer

- Kevlar overgår i slag- og slidstyrke

- Glasfiber tilbyder en god balance af egenskaber til lavere omkostninger

Mange brugerdefineret komposit produkter bruger faktisk en blanding af glas- og kulfibre for at skabe balance mellem ydeevne og pris. For de fleste forbrugsvarer giver denne hybridtilgang mere mening end at bruge ren kulfiber eller kevlar.

Pickleball-padler af kulfiber vs. pickleball-padler af kevlar

Pickleball er blevet enormt populært, og padelmaterialet spiller en stor rolle i dit spil. Lad os sammenligne pickleball-padler af kulfiber med pickleball-padler af kevlar:

Pickleball-padler af kulfiber:

- Giver enestående kraft og kontrol

- Er meget lette

- Tilbyder en fast, responsiv følelse

- Har minimal fleksibilitet

- Giver en sprød "pop"-lyd, når du rammer

Kevlar pickleball-padler:

- Absorberer stød bedre

- Giv et godt touch til bløde skud

- Er lettere og mere behagelig at spille på i længere tid

- Har tendens til at være mere stille

- Har bedre holdbarhed

Hvad er bedst? Det afhænger af din spillestil. Rene kulfiberpadler er kendt for kraft og præcision. Spillere, der slår hårdt og vil have maksimal kontrol, foretrækker dem ofte.

Kevlar pickleball-padler giver mere tilgivelse og følelse. De er ofte bedre for spillere, der sætter pris på berøringsskud og ønsker at reducere træthed i armen.

Mange af de bedste pagajer kombinerer faktisk begge materialer, med kulfiber til kernestrukturen og kevlar i de områder, der udsættes for større belastning.

Sammenligning af omkostninger: Kulfiber vs. kevlar

Både kulfiber og kevlar er førsteklasses materialer, men de har forskellige prisniveauer:

Kulfiber:

- Rå kulfiber koster $10-$24 pr. pund

- Færdige kulfiberprodukter har høje priser

- Produktionen er kompleks og kræver specialiseret udstyr

- Spild under produktionen kan være stort

Kevlar:

- Rå kevlar koster $8-$15 pr. pund

- Forarbejdning er noget enklere end kulfiber

- Produkterne har tendens til at være billigere end sammenlignelige kulfiberprodukter

- Mere alsidig i fremstillingsmetoder

Omkostningsforskellen er en af grundene til, at mange producenter vælger kun at bruge kulfiber, hvor der virkelig er brug for dets unikke egenskaber. For kulfiber motorcykler og andre højtydende anvendelser er den ekstra pris vægtbesparelsen og stivheden værd.

For de fleste forbrugerprodukter giver en hybrid tilgang med flere materialer ofte mest mening, både hvad angår ydeevne og omkostninger.

Konklusion: At vælge mellem kulfiber eller kevlar

Når du skal vælge mellem kulfiber og kevlar, skal du overveje, hvilket problem du forsøger at løse:

- Har du brug for maksimal stivhed og minimal vægt? Vælg kulfiber.

- Har du brug for slagfasthed og fleksibilitet? Vælg Kevlar.

- Vil du have det bedste fra begge verdener? Se efter kulfiber- og kevlar-kompositter.

Begge materialer har fortjent deres plads blandt de mest imponerende tekniske materialer, vi har. Deres høje styrke/vægt-forhold gør dem ideelle til anvendelser, hvor vægten betyder noget. Deres unikke egenskaber har ændret industrier fra sport til rumfart.

Her er en hurtig opsummering af, hvad vi har lært:

- Kulfiber udmærker sig ved stivhed, vægt og udseende

- Kevlar udmærker sig ved slagfasthed, slidstyrke og fleksibilitet

- At kombinere dem skaber materialer med de bedste egenskaber fra hver

- Glasfiber tilbyder et mere overkommeligt alternativ med god all-around performance

- Specifikke anvendelser som pickleball-padler viser, hvordan valget mellem materialer påvirker ydeevnen

Det vigtigste at tage med:

- Kulfiber er 5 gange stærkere end stål, men meget lettere

- Kevlar kan stoppe kugler, mens det stadig er let nok til at bære

- Forskellene mellem kulfiber og kevlar gør dem velegnede til forskellige formål

- Mange højtydende produkter bruger begge materialer sammen

- Dine specifikke behov bør styre dit materialevalg

- Overvej omkostninger, holdbarhed, vægt og krav til ydeevne, når du beslutter dig

Som ledende kulstoffabrikVi forstår de unikke fordele ved hvert materiale. Uanset om du har brug for kulfiberdele, Kevlar-komponenter eller en blanding af begge dele, så starter det rigtige valg med at forstå, hvad der gør hvert materiale specielt.