How We Make Carbon Fiber Parts: From Start to Finish

The Big Problem with Carbon Fiber

Making carbon fiber parts is hard. Many companies try to make them but mess up. Why? They don’t know the right steps. They use bad materials. They rush the work. This leads to weak parts that break. It leads to parts that don’t fit right. It leads to parts that look bad.

Do you need strong parts that won’t break? Do you need parts that fit just right? Do you need parts that look good?

These problems make buyers mad. They waste money. They waste time. They have to start over.

Why This Gets Worse

The problem gets worse when:

- You need lots of parts fast

- You need parts that match just right

- You need help fixing the design

- You need to meet strict rules

- You need the best price for carbon fiber fabric.

When things go wrong with carbon fiber parts, it can stop your whole project. Cars sit half-done. Bikes can’t be sold. Aircraft get stuck on the ground.

Buyers feel stuck. They’ve spent money but don’t have good parts. They miss their launch dates. Their customers get mad.

Our Simple Answer: 28+ Years of Making It Right

We know how to make carbon fiber parts the right way. We’ve been doing it for 28+ years. We use the best materials. We follow the right steps. We check our work over and over.

Let us show you how we turn carbon fiber into parts you’ll love.

Step 1: We Pick the Right Materials

We start with the best materials:

| Material Type | What It Does | Why It Matters |

|---|---|---|

| PAN precursor | The main fiber building block | Makes parts strong |

| Lignin-based fiber | A green option that costs less utilizes carbon fiber with epoxy. | Uses 40% less money to make |

| Prepreg materials | Carbon fiber with resin already in it enhances the composite strength. | Makes parts more the same |

| Recycled carbon fiber | Reused fiber for some parts | Helps the earth, costs less |

We pick what works for your job. Need parts that are super strong? We use aerospace-grade carbon fiber. Need to save money? We might use some recycled carbon fiber that still works well.

Step 2: We Shape the Fiber Just Right

Now we turn fiber into the shape you need. We use these ways:

- Vacuum infusion – For big, light parts

- Prepreg molding – For super strong parts

- 3D printing – For fast, tricky shapes

- Resin transfer molding – For smooth parts

- LFI technology – For making lots of parts fast

Each way has good points. Our carbon fiber car parts need to be super strong. So we often use prepreg molding for them.

For custom carbon fiber parts, we might use 3D printing. It lets us make weird shapes fast.

Step 3: We Make the Parts Strong

Next, we make the parts strong. We use heat in a smart way.

Old ways use lots of power. Our new ways use less:

- Microwave heating – Uses 70% less power

- Plasma technology – Makes parts just as strong, but faster

- Smart curing – Uses just the right heat at just the right time

This saves money. It makes parts ready faster with a precise layup technique. It helps the earth too by using sustainable manufacturing processes.

Step 4: We Make Sure Parts Are Perfect

We check each part many ways:

- We look at it closely

- We measure it

- We test how strong it is

- We see if it fits right

- We make sure it looks nice

If a part isn’t right, we don’t send it. This means you get only good parts.

How Our Way Helps You Win

Our way of making carbon fiber parts helps you in big ways:

For Car Makers

We make parts that:

- Are light but strong

- Look great

- Fit just right

- Pass all safety tests

Our carbon fiber car parts help cars go faster while using less gas.

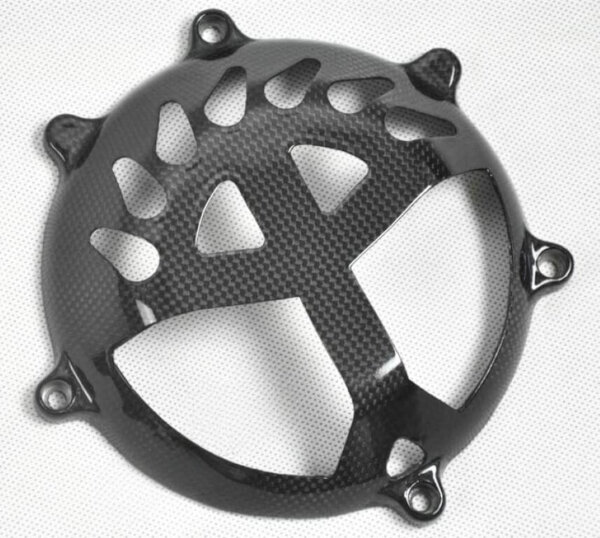

For Bike Builders

We make parts that:

- Are super light

- Look cool

- Are strong in crashes

- Last a long time

Check out our carbon fiber motorcycle parts that riders love.

For Aircraft Makers

We make parts that:

- Meet strict air rules

- Are the same every time

- Save lots of weight

- Stand up to tough use

Real Success Stories

Story 1: BMW’s New Console

BMW needed a center part for a new car coming in 2027. They wanted it light. They wanted it strong. They wanted it to look good.

We used our 3D printing way to make it with carbon fiber fabric. This cut the time by 40%. It saved weight too. BMW loved it.

Story 2: Wind Power Parts

A wind power company needed big parts that don’t break. They needed them to last 20+ years outside. And they needed a good price.

We used our CARBOWAVE method. It cut power use by 70%. It made parts just as strong. The company saved money and got great parts.

Story 3: Race Car Team

A race team needed new parts fast. Their old ones broke. The race was in two weeks.

We made new, better parts in just 10 days. They were 30% stronger due to the use of fiber and resin. The team won their race!

Why Pick Us Over Others

Here’s why smart companies pick us:

- 28+ years of know-how – We’ve seen and fixed all the problems

- Custom help – We make what YOU need, not what’s easy for us

- Fast work – We get parts to you when you need them

- Fair prices – We don’t waste money, so you pay less

- Green methods – We use less power and less waste

What Our Way Costs

Our prices are fair. Here’s what makes the cost go up or down in the manufacturing process:

- How many parts you need

- How big the parts are

- How strong they need to be

- How fast you need them

- What they look like

We’ll tell you the price up front. No surprises later.

How Our Process Works

- You tell us what you need

- We help fix your design if needed

- We pick the right way to make it

- We make a test part for you to check

- You say “yes” or ask for changes

- We make all your parts

- We check each one

- We pack them safe and ship them

- You get great parts on time

It’s that simple!

New Ways We’re Getting Better

We keep finding better ways to make carbon fiber parts:

Lignin-Based Carbon Fiber

We now use plant leftovers to make carbon fiber. It costs much less when using epoxy resin. It uses less oil. It works just as well.

Carbon Fiber Recycling

We can now reuse old carbon fiber. This saves money. It helps the earth. The parts are still strong.

Microwave Methods

Our new CARBOWAVE way uses 70% less power. It makes parts just as good. It’s faster too.

Smart Materials

We’re testing carbon fiber that can:

- Tell you when it’s about to break

- Heat up when it’s cold

- Fix small cracks by itself

Tools We Use

We use the best tools, including advanced 3D printing filament.

- High-end autoclaves – For perfect heating

- Computer cutting – For exact shapes

- Laser scanners – To check each part

- Robot helpers – For the same work every time

- 3D printers – For fast test parts

These tools help us make better parts. They help us work faster using advanced composite materials. They help keep prices fair.

What Our Customers Say

“We tried three other makers before finding Scomp. They got it right the first time. Now we only use them.” – Car Parts Company specializing in composite materials.

“They helped fix our design to make it stronger AND cheaper. Great partner!” – Bike Maker

“On time, on budget, no drama. Just what we needed.” – Aircraft Parts Buyer

How to Start

Ready for great carbon fiber parts? Here’s how to start:

- Send us your design (or tell us what you need)

- Tell us how many parts you need

- Tell us when you need them

- We’ll show you how we can help

Email us: [email protected] Call us: +86-136 2619 1009

FAQ About Our Carbon Fiber Work

Q: How long does it take to make parts? A: Small, simple parts: 1-2 weeks. Big, complex parts: 3-6 weeks.

Q: What’s your minimum order? A: We can make just one part if that’s all you need!

Q: Can you help fix my design? A: Yes! We do this all the time to make parts better.

Q: Do you make parts for anyone, including aerospace companies? A: Yes – cars, bikes, planes, boats, sports gear, and more.

Q: Is your carbon fiber strong enough for racing? A: Yes! Many race teams use our parts.

Ready to Solve Your Carbon Fiber Problems?

Stop wasting time with bad parts. Stop paying too much. Stop missing your launch dates.

Start getting perfect carbon fiber parts. Start saving money by switching to composite materials. Start making your customers happy.

Contact us today and let’s make something great together!