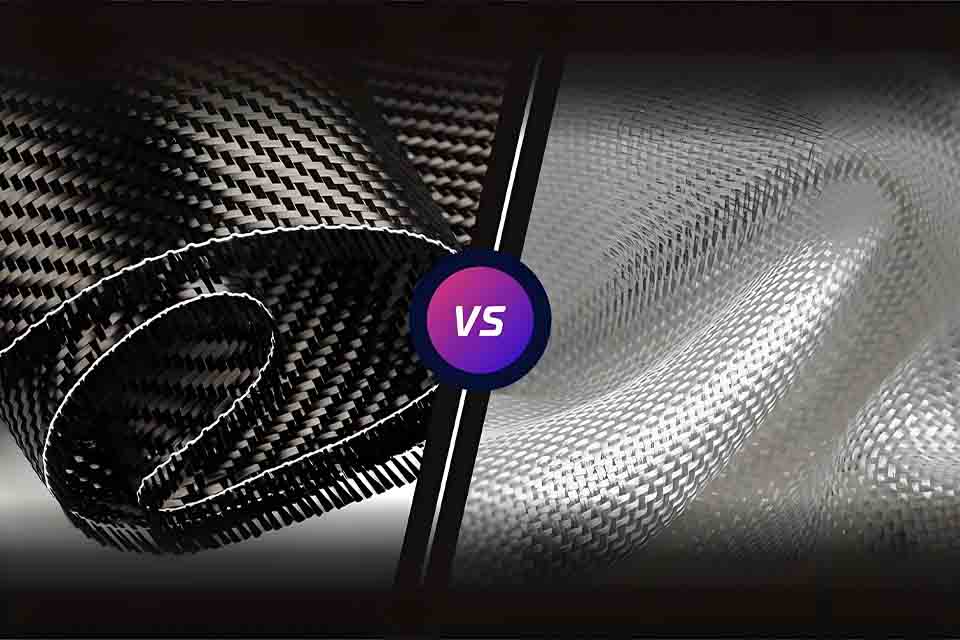

Carbon Fiber vs Fiberglass: Why Lighter is Better for Your Project

The Weight Problem

Do you want to make things that go fast? Do you need parts that are strong? Are your products too heavy?

Many makers face these big problems. They try to pick the right stuff to build with. They must pick between carbon fiber and fiberglass.

What if you pick the wrong one? Your things might:

- Break when used

- Cost too much

- Be too heavy

- Not last long

The wrong pick can make you lose money. It can make your customers sad.

Why This Choice Hurts

Think about what happens when you pick the wrong stuff:

- Cars that use too much gas

- Bikes that are hard to ride

- Planes that can’t fly far

- Boats that go too slow

When parts are too heavy, they hurt how things work. They use more fuel. They break more. They cost more to fix.

Do you want your products to fail? Do you want mad customers?

The Carbon Fiber Answer

We make custom carbon fiber parts that fix these problems!

Our factory can make carbon fiber parts that are 15-30% lighter than the same parts made from fiberglass. This makes a big change in how your products work.

We offer:

- OEM/ODM service

- Custom designs

- Full testing

- Fast making

- Smart help

Let’s see how carbon fiber beats fiberglass in all the ways that count!

Carbon Fiber vs Fiberglass: The Big Face-Off

| What We Check | Carbon Fiber | Fiberglass | Why It Matters |

|---|---|---|---|

| Weight | Very light | Heavier | Lighter parts make things go faster and use less fuel |

| How Strong | Very strong | Less strong | Strong parts don’t break and last longer |

| Cost | Higher | Lower | We help you find the right price for what you need |

| How Long It Lasts | Very long | Long | Things that last save you money over time |

| How It Looks | Very nice | Nice | Good looks make customers happy |

Why Carbon Fiber is Lighter

Carbon fiber is not just a bit lighter. It is A LOT lighter!

Some facts:

- Carbon fiber is 15-30% lighter than fiberglass

- Carbon fiber is 4 times stronger

- Carbon fiber is 6 times stiffer

When you use our carbon fiber in your carbon fiber car parts, they will be much lighter. This means the car will:

- Go faster

- Use less gas

- Turn better

- Stop quicker

What Makes Carbon Fiber So Good?

Carbon fiber is made from tiny strings of carbon. These strings are thinner than hair. They get put in a special glue. This makes a very strong mix.

The way we make carbon fiber is what makes it so light and strong:

- We put the carbon strings in rows

- We add the special glue

- We use heat and push on it

- We shape it how you want

- We make it smooth and pretty

This way of making things is why our carbon fiber is better than fiberglass.

When to Pick Carbon Fiber

Not all jobs need carbon fiber. But for some, it is the only choice!

Best Times for Carbon Fiber:

- Race cars: When you need to go fast and win

- Sport bikes: For the carbon fiber motorcycle parts that make riding fun

- Planes: When weight saves fuel

- Boats: To go fast on water

- Sports gear: For the edge that helps you win

Best Times for Fiberglass:

- Home parts that don’t move

- Big parts where cost matters more

- Parts that get hit a lot

- Parts that must bend a lot

Our Custom Carbon Fiber Service

We don’t just sell carbon fiber. We make the exact parts you need!

Our custom carbon fiber service helps you:

- Plan your part

- Draw your part

- Test your part

- Make your part

- Check your part

- Ship your part

We work with you from start to end. We make sure you get the best parts.

How We Make Your Parts

Our factory uses the best ways to make carbon fiber parts:

- Hand Lay-up: For the most exact parts

- Vacuum Bag: To make parts with no air holes

- Resin Transfer: For the smoothest finish

- Compression Molding: For parts that must be the same each time

We pick the right way for your job. This means you get the best parts at the right price.

Why Our Customers Pick Us

Customers from all over the world pick us for their carbon fiber needs:

“The carbon fiber hood you made for my car cut 12 pounds off! It made my car faster and it looks great!” – Tom, Race Car Builder

“We tried 3 other makers before we found you. Your carbon fiber bike parts are the best we’ve used.” – Jane, Bike Shop Owner

Our parts work in the real world. They help our customers win races, save fuel, and make better products.

The Cost Truth

Let’s be clear: carbon fiber costs more than fiberglass.

But you need to think about all the costs:

- How much to buy

- How long it lasts

- How much it saves (fuel, time, wins)

- How it makes customers feel

When you look at all costs, carbon fiber is often the smart pick!

How to Start with Our Carbon Fiber

Want to make your products lighter, stronger, and better? Here’s how to start:

- Tell us what you need

- We make a plan with you

- We show you what it will cost

- We make a test part

- You check the test

- We make your parts

It’s that easy to start making better products with our carbon fiber!

The Carbon Fiber Future

The world is moving to carbon fiber. More cars, planes, bikes, and boats use it each year.

By using our carbon fiber now, you:

- Stay ahead of others

- Make better products

- Make customers happy

- Save money over time

- Help the earth by using less fuel

Common Questions

Is carbon fiber really worth the extra cost?

Yes! When weight matters, carbon fiber pays for itself in better performance, fuel savings, and happy customers.

Can you make any shape in carbon fiber?

Almost any shape! Our factory can make very complex parts. Just show us what you need.

How long do carbon fiber parts last?

Very long! Carbon fiber doesn’t rust or rot. It can last for decades with proper care.

Do you have minimum orders?

We work with all size orders! From one test part to thousands of production parts.

Can you match my design exactly?

Yes! Our custom carbon fiber service makes parts that match your specs exactly.

Ready to Make Better Products?

The choice is clear: when you need lighter, stronger parts, carbon fiber is the answer!

Our factory is ready to help you make the best parts. We have the tools, skills, and experience to make your carbon fiber dreams real.

Don’t let heavy, weak parts hold your products back. Contact us today to start your carbon fiber project!