Carbon Fiber vs. Fiberglass: Which Material Is Stronger?

The Quick Answer

Yes, carbon fiber is stronger than fiberglass. It’s about 3 to 7 times stronger when you compare how much force each material can handle. But here’s the catch: fiberglass costs way less and doesn’t break as easily when something hits it hard.

Think of it this way. Carbon fiber is like a superhero—super strong but expensive. Fiberglass is like your reliable friend—tough enough for most jobs and won’t empty your wallet.

Understanding Material Strength: What Really Matters

Before we dive deep, let’s talk about what “strong” actually means. Strength isn’t just one thing.

Tensile strength means how much pulling force a material can take before it snaps. Stiffness (also called modulus of elasticity) tells us how much a material bends under pressure. Impact resistance shows how well something bounces back when you hit it.

Carbon fiber wins at tensile strength and stiffness. However, fiberglass takes the crown for impact resistance.

The Numbers Don’t Lie: Strength Comparison

Let’s look at the hard data. Carbon fiber has a tensile strength between 500 and 700 ksi (that’s 3,400 to 4,800 MPa). Fiberglass sits at 100 to 300 ksi (700 to 2,000 MPa).

What does this mean in real life? Carbon fiber composite materials can handle way more force before breaking. That’s why companies like Boeing use carbon fiber for 50% of the 787 aircraft structure. The plane needs to be super strong but also super light.

For stiffness, carbon fiber scores 33 to 50 Msi (228 to 345 GPa). Fiberglass only reaches 3 to 12 Msi (21 to 83 GPa). This massive difference matters for things like carbon fiber cars and racing bicycles where every bit of flex wastes energy.

Real-World Strength Examples

Formula 1 teams build their race car bodies (called monocoques) from carbon fiber. Why? Because a crash at 200 mph requires materials that won’t crumble. The carbon fiber chassis protects the driver while keeping the car light enough to win races.

On the other hand, fiberglass boat hulls rule the water. Boats slam into waves constantly. Fiberglass flexes and absorbs that punishment without cracking. It’s the perfect choice for kayaks, sailboats, and even massive yachts used in races like the America’s Cup.

Weight Matters: Density Comparison

Carbon fiber weighs 1.5 to 1.6 grams per cubic centimeter. Fiberglass comes in at 2.5 to 2.7 grams per cubic centimeter. That’s almost twice as heavy!

For aerospace projects, this weight difference is huge. NASA and SpaceX use carbon fiber for rocket fairings because every pound matters when you’re launching into space. Less weight means less fuel and lower costs.

The BMW i-Series cars use carbon fiber for their chassis. This makes the electric cars lighter, which means the battery lasts longer. Tesla, Lamborghini, and McLaren Automotive also use carbon fiber parts to cut weight.

But here’s where it gets interesting. Corvette has used fiberglass composite bodies since the 1950s. For a street car that doesn’t need to be ultra-light, fiberglass works great and costs less.

Durability: Which Lasts Longer?

Carbon fiber resists corrosion brilliantly. It doesn’t rust. It doesn’t rot. Companies like Owens Corning and Hexcel Corporation produce materials that last for decades.

Wind turbine manufacturers like Vestas and GE use carbon fiber for turbine blades because they need to spin for 20+ years in harsh weather. The material barely expands or contracts with temperature changes, which keeps everything working smoothly.

However, carbon fiber has a weakness. It’s brittle. Drop something on it or hit it with a sharp object, and it might crack. Once cracked, carbon fiber repair gets expensive and tricky. You often need special equipment like an autoclave (basically a pressure cooker for composites).

Fiberglass durability shines in impact situations. It bends instead of breaking. That’s why motorcycle helmets from companies like Bell Helmets and Schuberth often use fiberglass or a mix of both materials. Your helmet needs to absorb impact energy, not shatter.

The UV and Moisture Challenge

Fiberglass absorbs moisture over time. If you’ve ever seen an old fiberglass boat or pool, you might notice the surface looks dull or chalky. UV rays from the sun break down the resin that holds the glass fibers together.

Carbon fiber handles UV better, but it’s not perfect. That’s why custom carbon fiber products often get a protective coating.

Cost Analysis: Your Budget Matters

Let’s talk money. Carbon fiber costs between $10 and $40 per pound for raw material. Fiberglass runs $2 to $8 per pound. That’s a 5 to 10 times difference!

Manufacturing makes the gap even bigger. Making carbon fiber parts requires:

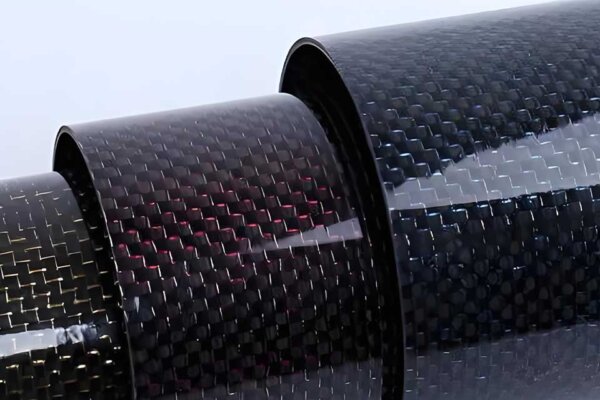

- Special prepreg materials (fabric pre-soaked in resin)

- Autoclave curing at high temperature and pressure

- Skilled workers who know layup techniques

Fiberglass molding is simpler. You can do hand layup in a garage. The resin compatibility is easier to work with. Many small businesses and boat builders choose fiberglass because they don’t need fancy equipment.

Companies like Toray Industries, Mitsubishi Chemical Carbon Fiber, and Teijin Carbon work constantly to bring carbon fiber costs down. But it’s still not cheap.

Best Applications: When to Use Each Material

Choose Carbon Fiber For:

Aerospace and Aircraft

- Airbus and Lockheed Martin use it for aircraft parts

- Firefly Aerospace builds rocket components

- Weight savings directly translate to fuel savings

High-Performance Vehicles

- Formula 1 race cars need the stiffness

- Bugatti Chiron and Porsche 911 GT3 use it for speed

- Ducati and BMW Motorrad add it to motorcycles

Premium Sports Equipment

- Specialized Bicycles, Trek Bikes, and Giant Bicycles make carbon fiber frames

- Callaway Golf and TaylorMade produce carbon fiber golf clubs

- Professional tennis rackets and hockey sticks use it

Medical and Prosthetics

- Companies like Össur and Ottobock make carbon fiber foot inserts

- Lightweight prosthetic limbs help patients move easier

- Exoskeletons for rehabilitation need strength without bulk

Choose Fiberglass For:

Marine Applications

- Boat hulls for everything from dinghies to yachts

- Hobie Cat makes fiberglass kayaks

- Swimming pools that need to hold water for years

Budget Automotive Parts

- Automotive panels like hoods and bumpers

- Honda CBR and other motorcycle fairings

- Custom car bodies where cost matters more than weight

Industrial Uses

- Chemical storage tanks (fiberglass resists many chemicals)

- Construction materials like roofing panels

- Pipes and ducts for harsh environments

Consumer Products

- Fiberglass surfboards from brands like Patagonia

- Playground equipment

- Garden ponds and decorative features

Hybrid Solutions: Getting the Best of Both

Smart engineers don’t always pick just one. Hybrid composites combine carbon fiber and fiberglass to balance performance and cost.

For example, some fishing rods from Shimano use carbon fiber for the tip (where sensitivity matters) and fiberglass for the base (where flex and strength matter). This gives you the best feel when a fish bites, plus the power to reel it in.

DJI drones often mix materials too. The frame might be carbon fiber for lightness, but landing gear might be fiberglass because it needs to absorb impact.

Working with a custom composite factory lets you design exactly the mix you need for your project.

Manufacturing Methods: How Each Material Gets Made

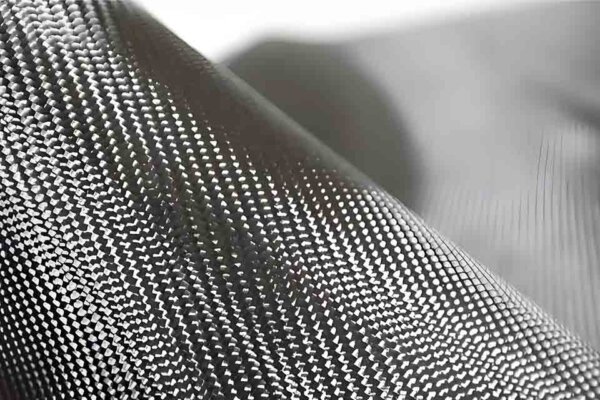

Carbon fiber manufacturing starts with special fibers (often made from a material called PAN). These get:

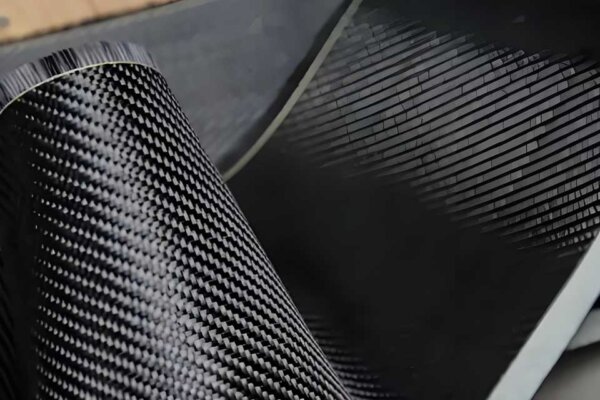

- Woven into fabric or kept as unidirectional sheets

- Combined with epoxy resin

- Laid up in molds using vacuum bagging

- Cured in an autoclave under heat and pressure

Companies like SGL Carbon and Zoltek produce millions of pounds of carbon fiber each year. The process is precise and requires clean rooms in some cases.

Fiberglass production is more forgiving:

- Glass fibers come as mat, fabric, or roving

- Workers apply resin by hand or spray

- The part cures at room temperature or in a simple oven

- No autoclave needed!

Methods like filament winding, pultrusion, and braiding work for both materials but are more common with fiberglass because the materials cost less.

Failure Modes: How Each Material Breaks

Understanding how materials fail helps you pick the right one.

Carbon fiber develops delamination when layers separate. Once a crack starts, it spreads fast. The crack propagation happens suddenly, without much warning. Engineers call this “catastrophic failure.”

Fiberglass shows more warning signs. It might develop small cracks or white stress marks before total failure. This gives you time to fix problems. The fatigue life is shorter than carbon fiber under high stress, but the gradual failure mode can be safer.

Boeing learned this during the 787 development. They designed the carbon fiber structure to handle 10^7 cycles (that’s 10 million stress cycles) before needing inspection. Traditional aircraft made from aluminum need inspection more often.

Environmental Factors: Weather, Chemicals, and Temperature

Thermal expansion differs between materials. Carbon fiber barely expands or contracts with temperature. This matters for satellite components that go from freezing in Earth’s shadow to scorching in direct sunlight.

Fiberglass expands more, which can cause problems in precision applications. However, for fiberglass vs carbon fiber construction materials, this usually doesn’t matter much.

Chemical resistance is strong for both, but carbon fiber edges ahead. It’s basically inert—chemicals don’t attack it. Fiberglass can break down with some strong acids or bases, but it still handles most chemicals well.

Temperature limits favor carbon fiber for extreme heat. It maintains strength up to higher temperatures. But for cryogenic performance (super cold temperatures), both work fine. NASA uses both in space where temperatures swing wildly.

Electrical Properties: Conductivity and Shielding

Here’s something interesting. Carbon fiber conducts electricity. This can be good or bad!

Good: It provides EMI shielding (electromagnetic interference protection). Electronics in cars or aircraft stay protected from electrical noise.

Bad: If carbon fiber touches wiring, it can cause shorts. Lightning strikes on carbon fiber aircraft require special protection systems.

Fiberglass is an excellent electrical insulator. Power companies use it for:

- Ladder rails (so workers don’t get shocked)

- Antenna housings

- Radome materials (covers for radar equipment)

The radar transparency of fiberglass is much better than carbon fiber. That’s why aircraft radomes (the nose cone covering the radar) almost always use fiberglass, even on planes like the Boeing 787 that use carbon fiber everywhere else.

Medical and Safety Applications

Medical implants increasingly use carbon fiber. Why? It’s strong, light, and shows up well on X-rays (better X-ray transparency than metal implants). Surgeons can see broken bones even with the implant in place.

Prosthetic limbs from advanced manufacturers give amputees amazing mobility. A carbon fiber leg weighs way less than old-fashioned plastic and metal versions. Paralympic sports equipment made from carbon fiber helps athletes compete at the highest levels.

For armor and bulletproof materials, neither carbon fiber nor fiberglass work alone. Military applications combine them with materials like Kevlar and ceramics. The layers work together—each material handles different types of threats.

Motorcycle helmets and climbing gear need to meet strict safety standards. Many use fiberglass or a hybrid design because the impact resistance matters more than weight for most users.

Industry Examples: Who Uses What and Why

Let’s look at specific industries:

Automotive Racing

Formula 1 teams spend millions on carbon fiber. A complete monocoques costs $400,000 or more! But it saves the driver’s life in horrific crashes. Every F1 team from Red Bull Racing to Mercedes uses carbon fiber.

Consumer Vehicles

Most regular cars still use fiberglass or cheaper plastics. The Corvette proves fiberglass works great for street cars. Only expensive models like the BMW i3 or Lamborghini use significant carbon fiber.

If you’re considering carbon fiber cars for a custom project, think about whether you really need the performance or if you just want the cool look.

Marine Industry

Volvo Ocean Race boats push carbon fiber to the limit. These racing yachts circle the globe in extreme conditions. The weight savings let them sail faster.

Your weekend fishing boat? Fiberglass is perfect. It’s proven, durable, and if you scrape against a dock, repairs are cheap.

Sporting Goods

Professional athletes use carbon fiber bicycles, golf clubs, archery bows, and more. The performance edge matters when winning means money.

Weekend warriors often do fine with fiberglass or hybrid equipment. A $500 fiberglass fishing rod catches fish just as well as a $1,500 carbon fiber one for most people.

Wind Energy

Wind turbine blades get longer every year. Modern turbines have blades over 200 feet long! Carbon fiber vs fiberglass wind turbine blades is a hot topic. Carbon fiber allows longer blades that capture more energy, but costs more. Most manufacturers use carbon fiber just in critical areas and fiberglass for the rest.

Aerospace and Defense

Northrop Grumman, Lockheed Martin, and other defense contractors use carbon fiber for stealth aircraft. The B-2 bomber uses carbon fiber composites extensively. Military drones benefit from the weight savings.

NASA continues researching both materials. Different missions need different solutions.

Maintenance and Repair: Long-Term Ownership

Carbon fiber is low-maintenance if you don’t damage it. Clean it with soap and water. Don’t crash it. That’s about it.

But once damaged, repair gets complicated. You can’t just slap some putty on it. Professional repair requires:

- Grinding out damaged areas

- Applying new carbon fiber patches

- Vacuum bagging the repair

- Sometimes autoclave curing

This can cost hundreds or thousands of dollars.

Fiberglass repair is much simpler. Hardware stores sell fiberglass repair kits for $20. You can fix small damage yourself:

- Sand the damaged area

- Cut fiberglass mat to fit

- Mix resin and apply

- Sand smooth when dry

The US Coast Guard publishes guides for boat owners to repair fiberglass damage themselves.

Acoustic and Vibration Properties

Vibration damping differs between materials. Carbon fiber is stiffer, so it transmits vibrations more. This is why some premium bicycles use fiberglass in the seat stays—to smooth out road bumps.

Acoustic properties matter for some applications. Musical instruments like guitar bodies sometimes use carbon fiber, but many players prefer the sound of traditional materials. The ultra-stiffness changes how the instrument vibrates and produces sound.

Recycling and Environmental Impact

Neither material is great for the environment, but carbon fiber is worse.

Fiberglass recyclability is limited. You can grind it up and use it as filler in concrete or other materials. Not perfect, but possible.

Carbon fiber is even harder to recycle. The expensive fibers get locked in the cured resin. Breaking them apart while keeping the fibers useful is difficult and expensive. Researchers work on this problem, but we’re not there yet.

If environmental impact matters to you, consider how long the product will last. A carbon fiber bike frame might last 20 years. A cheap fiberglass one might last 5 years before breaking. Over time, the longer-lasting product might be more sustainable even if it’s harder to recycle.

3D Printing and New Technologies

3D printing with both materials is advancing. Companies like Markforged make printers that can print carbon fiber-reinforced parts. This opens up new possibilities for custom carbon fiber products without expensive molds.

Fiberglass 3D printing is less common but emerging. The technology isn’t quite ready for prime time, but it’s coming.

Traditional carbon composite manufacturers like this one still handle the highest-quality work, but 3D printing is democratizing access to these materials for small businesses and hobbyists.

Making Your Decision: Which Should You Choose?

Here’s a simple decision tree:

Choose carbon fiber if:

- Weight is critical to performance

- You need maximum stiffness

- Your budget allows it

- The item won’t face harsh impacts

- You’re building something for racing or aerospace

Choose fiberglass if:

- Cost is a major factor

- Impact resistance matters more than weight

- You might need to repair it yourself

- You’re building something large where weight isn’t critical

- You need electrical insulation

Consider a hybrid if:

- You need some carbon fiber benefits but can’t afford all carbon

- Different parts of your project have different requirements

- You’re balancing multiple factors

Future Trends and Innovations

Material science keeps advancing. Graphene (a cousin of carbon fiber) promises even better properties, but costs way more currently. Researchers work on making carbon fiber from cheaper materials like lignin (a wood byproduct).

Automated fiber placement robots are making carbon fiber manufacturing faster and cheaper. Companies like Airbus use robots to lay up parts with perfect precision.

New resins and epoxy bonding techniques improve both materials constantly. The carbon fiber vs fiberglass debate will continue, but both materials will get better over time.

The Bottom Line

So, is carbon fiber stronger than fiberglass? Absolutely. It’s roughly 3 to 7 times stronger in tensile strength and way stiffer.

But “stronger” doesn’t always mean “better.” Fiberglass has benefits that carbon fiber can’t match:

- Lower cost

- Better impact resistance

- Easier repair

- Simpler manufacturing

For most applications, you don’t need the ultimate strength of carbon fiber. A fiberglass boat hull works perfectly. Fiberglass automotive panels are fine for street cars. Fiberglass sporting goods serve most athletes well.

However, when performance matters most—in aerospace, racing, or premium products—carbon fiber is worth every penny. Boeing, SpaceX, Formula 1, and countless others prove that the extra cost pays off when you need the best.

Understanding your specific needs helps you make the right choice. Work with experts, consider your budget, and think about long-term costs including maintenance and repairs.

Whether you choose carbon fiber, fiberglass, or a hybrid solution, modern composite materials offer incredible capabilities. These materials help us build faster vehicles, lighter aircraft, better sporting equipment, and innovative products that weren’t possible 50 years ago.

The future of both materials looks bright as manufacturing improves and costs come down. Who knows? Maybe in 10 years, carbon fiber will be cheap enough for everyone. Until then, choose wisely based on your specific needs—and enjoy the amazing capabilities both materials provide!

Author / About This Article

Written by engineers from a custom composite manufacturing factory with experience in carbon fiber and fiberglass parts for automotive, aerospace, marine, and industrial applications.

Typical mechanical properties are based on industry-standard composite materials and publicly available manufacturer data.