Is Carbon Fiber a Polymer? What You Need to Know

The Problem: Confusion About Carbon Fiber

Do you get mixed up about carbon fiber? Lots of people think carbon fiber is a polymer. But it is not. This mix-up can cause big headaches for folks who need the right stuff for their jobs.

When you pick the wrong material, it can:

- Make things break

- Cost too much money

- Waste your time

Why This Confusion Hurts Your Business

The mix-up gets worse when you try to make good things. You might pick materials that don’t work well. Your parts might not be as strong as they need to be.

Think about this: The carbon fiber market will grow to $94.74 billion by 2032! If you don’t know what carbon fiber really is, you might miss out on this big chance.

Your rivals who know the truth about carbon fiber will:

- Make better products

- Win more customers

- Earn more money

The Solution: Expert Carbon Fiber Manufacturing

Good news! We are carbon fiber experts. We make custom carbon fiber products that solve your problems. We know carbon fiber is not a polymer, but works best when joined with polymers to make strong parts.

As your OEM/ODM partner, we can help you make the right choice for all your carbon fiber needs.

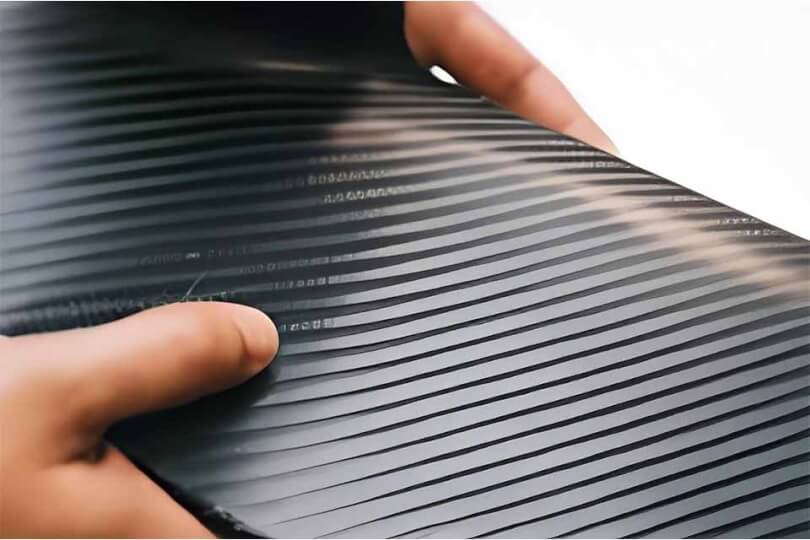

What Is Carbon Fiber, Really?

Carbon fiber is not a polymer. It is thin strings of carbon atoms. These strings are super strong and very light.

When we mix carbon fiber with polymers like epoxy, we get carbon fiber reinforced polymers (CFRP). These work like this:

- Carbon fiber gives strength

- Polymer holds it all together

Look at this simple table:

| Material | What It Is | What It Does |

|---|---|---|

| Carbon Fiber | Thin carbon strings | Gives strength |

| Polymer | Sticky stuff like epoxy | Holds fibers together |

| CFRP | Carbon fiber + polymer | Super strong and light |

Why Carbon Fiber Products Are So Good

Carbon fiber makes things that are:

- Very strong – Can hold lots of weight

- Super light – Won’t weigh you down

- Stiff – Doesn’t bend when you don’t want it to

- Long-lasting – Won’t rust or break easy

This is why carbon fiber cars go so fast and why planes use so much carbon fiber.

Markets That Need Carbon Fiber

The need for carbon fiber is growing fast! Look at who uses it:

- Planes: 35% of carbon fiber goes here

- Cars: 25% of carbon fiber goes here

- Wind power: 15% of carbon fiber goes here

- Hydrogen tanks: Growing 30% each year!

- Sports gear: Things like bikes and fishing poles

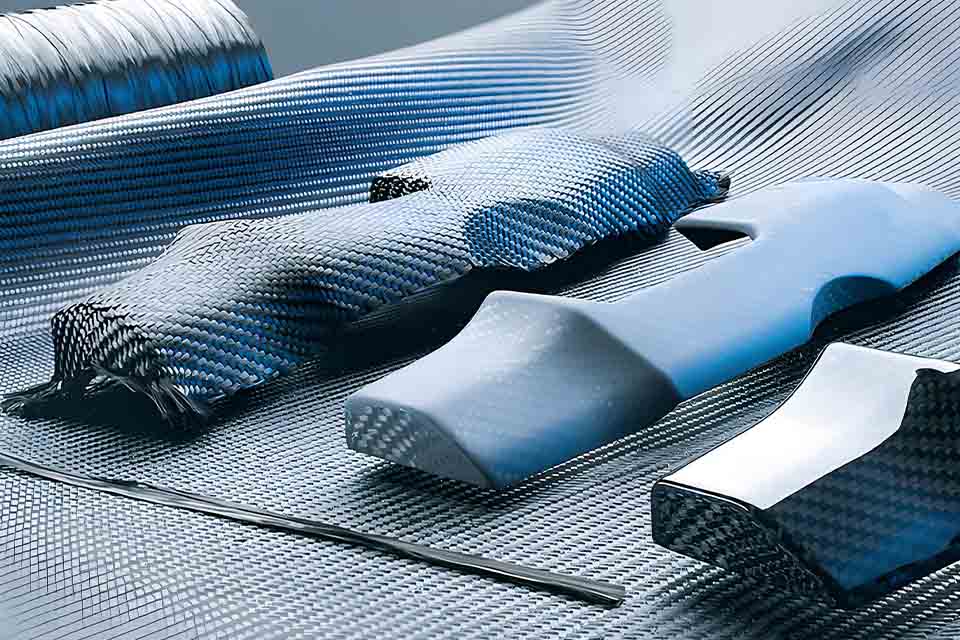

Our Carbon Fiber Manufacturing Process

We make top-notch carbon fiber parts using these steps:

- Design: We make plans that fit what you need

- Mold making: We build molds in the right shapes

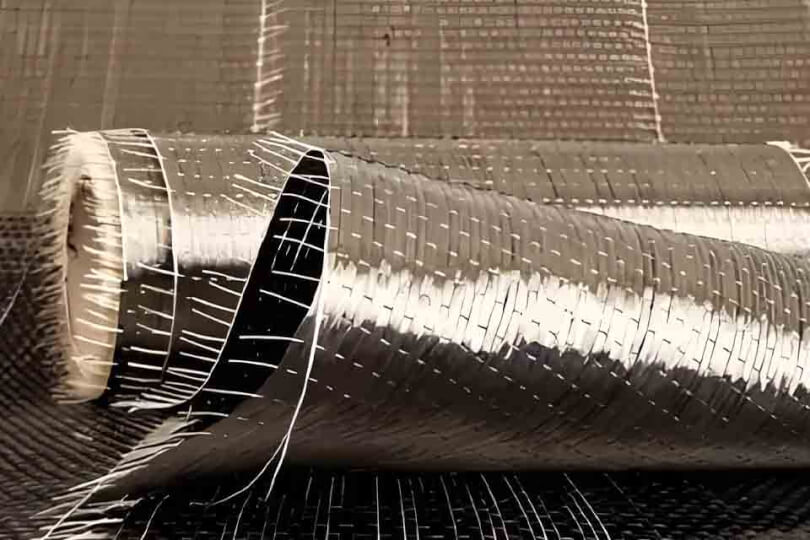

- Cutting: We cut carbon fiber cloth just right

- Layup: We put the cloth in the molds

- Resin: We add the polymer to hold it all

- Curing: We bake it so it gets hard

- Finishing: We make it look pretty

This makes parts that won’t let you down!

Custom Carbon Fiber Solutions We Offer

We can make any carbon fiber part you can think of! Some things we make:

For Cars

We make custom carbon fiber parts for cars like:

- Hoods that make cars lighter

- Dash parts that look cool

- Rear diffusers for Mercedes Benz that help cars go faster

For Bikes

Our carbon fiber motorcycle parts help bikes:

- Go faster with less weight

- Look better with shiny carbon

- Last longer than plastic parts

For Sports

We make sports gear like:

- Carbon fiber gaffs for fishing that are strong

- Bike frames that are light

- Golf clubs that hit far

Why Our Carbon Fiber Manufacturing Is Best

When you work with us, you get:

- Expert knowledge: We know all about carbon fiber

- Custom work: We make what YOU need

- Top quality: Our parts don’t break

- Fast making: We don’t waste your time

- Good prices: You get what you pay for

We use the best mix of carbon fiber and polymer matrices to make parts that work just right for you.

How We Work With You

When you want us to make something, we:

- Listen to what you need

- Draw plans for your part

- Make a test part

- Check that it works right

- Make as many as you need

It’s that easy!

Special Way We Join Carbon Fiber Parts

One thing that makes us special is our carbon fiber frame joint connection design. This helps us:

- Make stronger joins

- Have lighter parts

- Make parts that last longer

Why Carbon Fiber Is Better Than Metal

Many people still use metal. But carbon fiber is better because:

| Thing | Metal | Carbon Fiber | Winner |

|---|---|---|---|

| Weight | Heavy | Very light | Carbon fiber! |

| Strength | Strong | Stronger | Carbon fiber! |

| Rust | Rusts | Never rusts | Carbon fiber! |

| Cost | Cheap | Costs more | Metal |

| Look | Plain | Very cool | Carbon fiber! |

As you can see, carbon fiber wins in most ways!

The Future of Carbon Fiber

The future is bright for carbon fiber! New things are coming:

- Cheaper ways to make carbon fiber

- Green carbon fiber from plants

- Recycled carbon fiber

- Smart carbon fiber that can sense things

We stay on top of these new things so we can make the best parts for you.

Real People Who Love Our Carbon Fiber

A race car team said: “Your carbon fiber parts made our car 12% lighter and we won the race!”

A bike maker said: “Since we used your carbon fiber frames, sales went up 30%! Folks love how they look and feel.”

A fishing pro said: “That carbon fiber gaff is the best I’ve ever used. It’s light but can pull in the big ones!”

How to Get Started With Us

Want to make something with carbon fiber? It’s easy:

- Tell us what you need

- We make a plan

- You say “Yes“

- We make it

- You get great parts!

Common Questions About Carbon Fiber

Q: Is carbon fiber a polymer? A: No! Carbon fiber is made of carbon atoms. It’s not a polymer. But it works great with polymers.

Q: Is carbon fiber plastic? A: No. Carbon fiber is not plastic. But we often mix it with special plastics to make strong parts.

Q: How long do carbon fiber parts last? A: A very long time! They don’t rust and can last for many years.

Q: Can you make any shape with carbon fiber? A: Yes! We can make almost any shape you can think of.

Get the Best Carbon Fiber Parts Now

Don’t waste time with the wrong stuff. Our carbon fiber parts will solve your problems. They are:

- Strong enough for hard jobs

- Light so they don’t slow you down

- Pretty so they look good

- Long-lasting so you don’t need to buy new ones soon

Visit our website to see what we can do. Let’s make something great together!