Carbon Fiber Aircraft C-Beams: To Lighter, Stronger, Faster

Problem: Why Old Aircraft Parts Hold You Back

Do you fly planes? Do you make planes? Old metal parts make planes too heavy. Heavy planes use more fuel. They fly less far. They cost more money to run.

Metal parts can rust and break. When they break, it is bad and scary. Planes must stay on the ground for long, costly fixes.

Many plane makers still use old, heavy metals when they could use better stuff.

Agitate: The Cost of Sticking with Metal Is High

What happens when you keep using metal parts?

- Your planes are 20-30% heavier than they need to be

- You spend more money on fuel every day

- Your planes can’t fly as far or carry as much stuff

- Metal parts wear out faster in bad weather

- You must fix them more often

- Your planes sit on the ground, not making money

In a world where every pound matters, metal C-beams are like carrying rocks in your backpack when you run. It slows you down and wears you out.

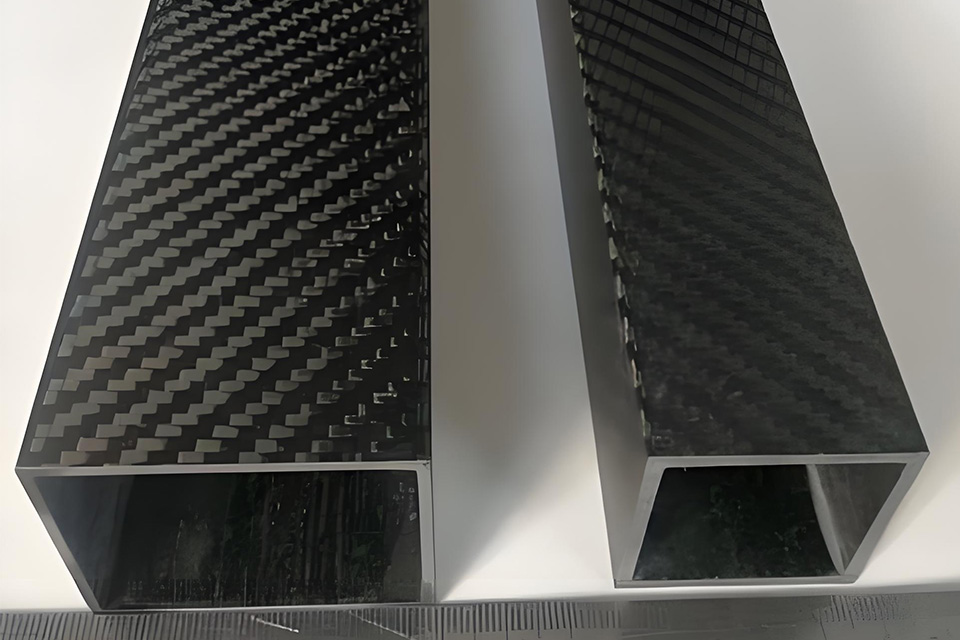

Solution: Carbon Fiber C-Beams – The Future Is Here Now

Our carbon fiber C-beams fix all these problems through aerospace-grade carbon fiber structural manufacturing, developed for weight-critical and safety-critical aircraft applications. With 28+ years making carbon fiber parts, we know how to make the best C-beams for any plane.

What Makes Our Carbon Fiber C-Beams Better?

Our C-beams are:

- Two times stronger than steel

- Much lighter than metal beams

- Do not rust or get weak in water

- Can handle very hot temperatures up to 2,200°C

- Last much longer than metal parts

The Science Behind Our Carbon Fiber C-Beams

Let’s look at what makes our C-beams so good:

Material Strength Comparison

| Property | Our Carbon Fiber C-Beam | Aluminum Beam | Steel Beam |

|---|---|---|---|

| Strength-to-Weight | 2× stronger than steel | 1× | 1× (baseline) |

| Rust Protection | High | Medium | Low |

| Heat Tolerance | Up to 2,200°C | ~300°C | ~600°C |

| Making Time | 2.5-3 hours | 6-8 hours | 4-5 hours |

How We Make Our C-Beams Better

Our factory uses the best ways to make carbon fiber parts:

- C-RTM Process: Makes parts with 60% fiber and less than 1% air bubbles

- Automated Fiber Placement: Puts carbon in the right spots with no waste

- Special Heating Methods: Makes parts that don’t need big, costly ovens

- 3D Winding: Creates parts that are strong where they need to be

Real Success Stories

Case Study: Airplane Floor Beams

A big airplane maker needed 12 floor beams for a new plane. They chose our carbon fiber beams because:

- They were 30% lighter than their old beams

- They could be made faster (in just 3 hours)

- They lasted longer in tests

- They saved thousands in fuel costs each year per plane

Case Study: Small Plane Wing Parts

A small plane maker had metal parts that kept cracking. We made them new carbon fiber beams that:

- Were 40% lighter

- Let their planes fly 20% farther

- Did not crack in tests

- Saved money on fuel and fixes

Why Choose Us For Your Carbon Fiber Aircraft C-Beams?

Our Long History

We have been making carbon fiber parts for 28+ years. In that time, we have:

- Helped hundreds of plane makers

- Made thousands of parts

- Solved many hard problems

- Built a team of top experts

Our Custom Services

We don’t just sell parts. We help you get exactly what you need:

- Custom Design: We help you plan the perfect parts

- Fast Making: We can make parts quickly when you need them

- Quality Tests: Every part is checked to be perfect

- Smart Pricing: Get great parts without spending too much

- Fast Shipping: Get your parts when you need them

How Our Process Works

When you work with us, it’s easy:

- Tell us what you need: Send us your ideas or plans

- We make a plan: Our team designs your parts

- We make a test part: You can see and try it

- We make your order: Fast, perfect, on time

- We ship to you: Anywhere in the world

Carbon Fiber C-Beam Manufacturing Excellence

Our factory uses the best ways to make carbon fiber parts. Here’s what makes our process special:

Our Manufacturing Strengths

- Fiber Volume & Air Space: Our C-beams have 60% fiber and less than 1% air bubbles [^3]

- Fast Production: We can make complex C-beams in just 2.5-3 hours

- Perfect Shapes: We can make C-beams, I-beams, T-beams, and more

- Strong Joints: Our special joining methods make parts that stay together

Our Quality Standards

Every C-beam we make must pass tough tests:

- Strength tests

- Bend tests

- Heat tests

- Air bubble checks

- Size checks

Applications for Our Carbon Fiber C-Beams

Our carbon fiber C-beams work great in many plane parts:

- Wing spars – the main parts that hold wings together

- Floor beams – hold up the floor in the plane

- Roof supports – keep the top of the plane strong

- Wall beams – make the sides of the plane stiff

- Door frames – strong but light frames for doors

Our beams are perfect for many types of aircraft:

- Small carbon fiber ultralight aircraft

- Business jets

- Big passenger planes

- Cargo planes

- Special planes for sports

Beyond Aircraft: More Uses for Our Carbon Fiber Beams

Our carbon fiber C-beams aren’t just for planes! They also work great in:

- Carbon fiber cars – makes them faster and uses less gas

- Carbon fiber motorcycles – faster and cooler

- Boats – lighter and faster on water

- Race cars – wins more races

- Buildings – stronger in earthquakes

Custom Carbon Fiber Solutions for Any Need

Need something special? We do custom carbon fiber parts too!

- Special sizes: Any length, width, or shape

- Special strength: Extra strong where you need it

- Special looks: Shiny, matte, or colored carbon

- Mixed materials: Carbon with other stuff for special jobs

Start Your Carbon Fiber C-Beam Project Today

Are you ready for better, lighter, stronger parts for your planes?

Call us today or send us an email to start talking about your needs.

Our team is ready to help you make your planes:

- Lighter

- Stronger

- Faster

- Cheaper to run

- More money-making

Don’t let heavy, weak metal parts hold your planes back. Switch to our carbon fiber C-beams and fly into the future!

Visit our main website at China Carbon Fibers to see all we can do.

Contact Us

Let’s make your planes better together!