Premium Carbon Fiber Drag Washers for Smooth Fishing Reel Performance

Table of Contents

Premium Carbon Fiber Drag Washers for Smooth Fishing Reel Performance

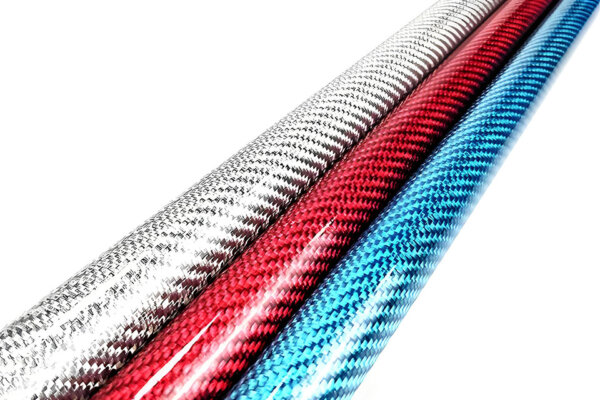

Welcome to our custom carbon fiber product manufacturing showcase! We make the best drag washers for fishing reels. Our carbon fiber drag washers make fishing better! They are smoother than old washers. They help catch more fish! Our washers work in many reels like Shimano, Daiwa, and Shakespeare. Made in our high-tech factory with top materials. We can make any size or shape you need.

Why choose our carbon fiber drag washers?

- Smoother drag than stock washers

- Last longer than regular washers

- Work in saltwater without problems

- Custom made to fit any reel model

- Big savings when you buy in bulk

Are you looking to upgrade fishing gear for your store? Or do you make fishing reels? We can help! Our carbon fiber drag washers make any reel better.

High-Performance Carbon Fiber Drag System for Better Fishing

Our carbon fiber drag washers make fishing better! The smooth drag helps catch more fish. When a fish pulls hard, our washers work just right. Not too loose, not too tight. This means fewer lost fish!

We use special carbon fiber that works better than stock drag washers. Our washers don’t get hot like metal ones. They stay smooth even when big fish pull hard. This helps in both freshwater and saltwater fishing.

Many pros pick our washers for bass fishing and inshore fishing. The smooth drag helps with light line and small hooks. This means more fish in your boat!

“After putting these carbon fiber drag washers in my reel, the performance improved instantly. The drag is so smooth now, I can fight fish better than ever!” – Professional Bass Angler

Custom Carbon Fiber Drag Washers for Any Reel Model

We can make drag washers for any reel! Just tell us what you need. We make washers for:

- Shimano reels

- Daiwa fishing reels

- Shakespeare models

- Pfleuger reels

- Many more brands!

Our factory can make any size or thickness you need. We can cut any hole size in the middle. We even make flat washers with no hole! This makes our washers great for repair jobs or upgrades.

The material we use is top quality carbon fiber. It’s better than what you find in stock reels. Our washers last longer and work better than metal ones. This means happy customers for you!

| Reel Brand | Washer Sizes Available | Custom Options |

|---|---|---|

| Shimano | 5mm – 30mm | Thickness, hole size |

| Daiwa | 8mm – 25mm | With/without grease |

| Shakespeare | 10mm – 22mm | Multi-pack kits |

| Pfleuger | 7mm – 20mm | Pre-greased option |

| Custom | Any size needed | Any specification |

DIY Carbon Fiber Drag Washer Sheets for Custom Cutting

Need to make your own drag washers? We sell carbon fiber sheets for DIY projects! Our sheets are easy to cut with common tools. You can make washers for any reel model.

The carbon fiber sheets come in different thickness options. This helps you match the exact needs of your project. Our sheets work great for:

- Replacement washers when exact parts aren’t available

- Custom drag for old reels

- Special performance upgrades

- Repair jobs on vintage reels

Each sheet can make many washers. This means big savings compared to buying pre-cut washers. We include tips for cutting perfect washers every time!

Technical Specifications of Our Carbon Fiber Drag Products

Our carbon fiber products are made with precision and care in our state-of-the-art manufacturing facility. Here are the detailed specifications: Carbon Fiber Drag Washer Specifications:

- Material: 100% carbon fiber

- Diameter Range: 5-40mm

- Thickness: 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm

- Hole Diameter Options: 2-15mm

- Temperature Resistance: Up to 200°C

- Water Resistance: 100% waterproof

- Pressure Tolerance: Up to 50kg/cm²

- Friction Coefficient: 0.15-0.25

Carbon Fiber Sheet Specifications:

- Sheet Sizes: 100×100mm, 150×150mm, 200×200mm

- Thickness: 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm

- Material: 100% carbon fiber

- Cutting: Can be cut with scissors, utility knife, or hole punch

How to Install Carbon Fiber Drag Washers

Installing our carbon fiber drag washers is easy! Here are simple steps:

- Open your reel by removing screws

- Find the drag stack inside the reel

- Note the order of all parts

- Replace old washers with our carbon fiber ones

- Apply drag grease if needed

- Put everything back in the same order

- Test the drag by pulling line

Important Tips:

- Use the right amount of drag grease

- Don’t over-tighten the drag screw

- Keep old washers as backup

- Clean all parts before putting back together

“Installing these carbon fiber drag washers transformed my old fishing reel. The drag is now smoother than when it was new!” – Tackle Shop Owner

Customer Testimonials

Here’s what our customers say about our carbon fiber drag washers:

“We started using these carbon fiber drag washers in all our custom reels. Our customers love the smooth drag and increased stopping power.” – Custom Reel Builder

“These washers outlast the original ones by years. Perfect for saltwater fishing where regular washers fail quickly.” – Tackle Shop Owner

“We’ve reduced our customer complaints by 80% since switching to these carbon fiber drag washers in our repair shop.” – Reel Repair Service

Environmental Benefits of Carbon Fiber Drag Washers

Our carbon fiber products aren’t just good for fishing – they’re better for the planet too! Environmental Advantages:

- Longer lifespan means less waste

- No harmful oils or chemicals used

- Replaceable parts extend reel life

- Lower carbon footprint than shipping whole new reels

- Less metal mining needed

By using our carbon fiber drag washers, you help reduce waste and support sustainable fishing!

Bulk Order Benefits for Businesses

Are you a business looking to order in bulk? We offer special advantages:

| Order Quantity | Price Discount | Free Services Included |

|---|---|---|

| 100-500 pcs | 10% off | Free shipping |

| 501-1000 pcs | 15% off | Free shipping + custom sizes |

| 1001-5000 pcs | 20% off | All above + custom branding |

| 5001+ pcs | 25% off | All above + dedicated service rep |

Business Customer Types We Serve:

- Fishing tackle manufacturers

- Reel repair shops

- Tackle retailers

- Custom rod and reel builders

- Fishing equipment distributors

- Tournament sponsors

Why Our Custom Carbon Fiber Manufacturing Makes the Difference

As a leader in custom carbon fiber product manufacturing, we bring unique advantages to our drag washers:

- Material expertise from working with aerospace and automotive industries

- Precision manufacturing learned from medical equipment production

- Innovative designs inspired by sports equipment development

- Quality control systems used in industrial equipment manufacturing

This means our carbon fiber drag washers benefit from technologies developed for much more demanding applications. When a fishing reel uses our washers, it gets the same quality that goes into carbon fiber parts for race cars and airplanes!

Our Manufacturing Capabilities

Our state-of-the-art factory can produce carbon fiber products for many industries:

- Automobile and motorcycle parts

- Aerospace components

- Sports equipment elements

- New energy device parts

- Medical equipment components

- Building decoration materials

- Consumer electronics parts

- Shipbuilding elements

- Industrial equipment components

This diverse experience helps us make the best fishing reel drag washers possible!

How to Order Custom Carbon Fiber Drag Washers

Ready to upgrade your fishing reels or inventory with our premium carbon fiber drag washers? Here’s how to order:

- Contact our team through our website

- Share your specifications (reel models, sizes, quantities)

- Get a custom quote within 24 hours

- Approve sample washers (for large orders)

- Place your order with our sales team

- Receive your premium carbon fiber drag washers!

For bulk orders, our team can help you determine exactly which sizes and specifications will work best for your needs.

Frequently Asked Questions

Q: What makes carbon fiber drag washers better than standard ones?

A: Carbon fiber drag washers provide smoother drag, longer life, better heat resistance, and consistent performance in all conditions.

Q: Can I use these in saltwater reels?

A: Yes! Our carbon fiber drag washers are perfect for saltwater use. They don’t corrode or degrade in salt environments.

Q: Do I need special grease for these washers?

A: We recommend using a quality drag grease, but our washers work with most standard reel greases.

Q: Can you match OEM washer specifications exactly?

A: Yes, we can match any original manufacturer specifications precisely, often with improved materials.

Q: What’s the minimum order quantity?

A: We can accommodate orders of any size, from single replacement sets to thousands of washers for manufacturing.

Q: How long do carbon fiber drag washers last?

A: With proper care, our carbon fiber drag washers typically last 3-5 times longer than standard washers.

Ready to Transform Your Reels with Premium Carbon Fiber Technology?

Our carbon fiber drag washers will take your reels to the next level! With smoother performance, longer life, and better fish-fighting ability, these washers are a game-changer.

Whether you need replacement parts for repairs, upgrade kits for improved performance, or bulk components for manufacturing, our custom carbon fiber manufacturing plant delivers quality that can’t be beat.

Contact us today to discuss your needs and discover how our carbon fiber technology can enhance your fishing experience or business! Get custom carbon fibers for your specific needs!

Learn about our carbon factory capabilities! Explore carbon fiber cars applications!

See carbon fiber motorcycles examples!

Contact our custom composite experts today!

Transform your fishing reels with our premium carbon fiber drag washers! Our custom-made washers deliver butter-smooth drag performance, longer life than stock parts, and perfect tension for landing more fish. Made with aerospace-grade carbon fiber technology, they’ll make your reels feel brand new again!

Carbon Fiber Composite Material Hot Pressing Molding Process

Our factory employs an advanced carbon fiber hot press process with a P20 steel mold, ensuring high efficiency, precision, durability, and cost-effectiveness for quality production.

Carbon Fiber Autoclave

Our factory runs 100+ hot pressure autoclaves, using aluminum molds and vacuum induction to shape carbon fiber with precision. High heat and pressure enhance strength, stability, and flawless quality.

Carbon Fiber Engineering Technology Research Center

Our Carbon Fiber Research Center drives innovation in new energy, intelligence, and lightweight design, using advanced composites and Krauss Maffei Fiber Form to create cutting-edge, customer-focused solutions.

Frequently Asked Question

Here are the answers to the frequently asked questions from the experienced carbon fiber products factory

We produce a wide range of carbon fiber components, including automotive parts, motorcycle parts, aerospace components, marine accessories, sports equipment, and industrial applications.

We primarily use high-quality prepreg carbon fiber and large-tow carbon fiber reinforced high-performance composites to ensure strength, durability, and lightweight characteristics.

Yes, our products are coated with UV-protective finishes to ensure long-lasting durability and maintain their polished appearance.

Yes, our facilities and equipment are capable of producing large-size carbon fiber components while maintaining precision and quality.

What are the benefits of using carbon fiber products?

Carbon fiber offers exceptional strength-to-weight ratio, corrosion resistance, stiffness, thermal stability, and a sleek, modern appearance.

We cater to automotive, motorcycle, aerospace, marine, medical, sports, and industrial sectors with a focus on lightweight and high-performance carbon fiber components.

Yes, we provide custom carbon fiber solutions tailored to your specifications, including unique designs, sizes, and patterns.

We utilize advanced technologies such as autoclave molding, hot pressing, and vacuum bagging, ensuring precision, stability, and quality in every product. wonders with the Hello Elementor Theme, we’re trying to make sure that it works great with all the major themes as well.

We use aluminum and P20 steel molds, designed for durability and high accuracy, to create complex and precise carbon fiber components.

Our products undergo rigorous quality control checks, including dimensional accuracy, material integrity, and performance testing, to meet industry standards.