CFRP vs Carbon Fiber: Key Differences Explained

When it comes to lightweight, durable materials with incredible strength, carbon fiber and CFRP (carbon fiber reinforced polymer) dominate the discussion. These materials are widely used in industries such as aerospace, automotive, and sports equipment, but they differ in several key areas. This article will dive deep into the differences between carbon fiber and CFRP, covering everything from their definitions and characteristics to applications and manufacturing processes.

What is Carbon Fiber?

Definition

Carbon fiber is a high-performance material made from carbon-rich synthetic fibers, like polyacrylonitrile (PAN), through processes such as oxidation, carbonization, and graphitization. It has over 90% carbon content and offers phenomenal mechanical and thermal properties.

Key Characteristics

Lightweight but Strong:

- Density: Less than 25% of steel.

- Tensile Strength: Over 3500 MPa, which is 7–9 times greater than steel.

- Elastic Modulus: Ranges between 23,000–43,000 MPa, making it rigid.

Thermal Properties:

- High Temperature Resistance: Operates above 2000°C.

- Low thermal expansion coefficient: Keeps its shape even in extreme heat.

Physical Performance:

- Corrosion resistant.

- Electrically conductive.

- Can be woven into fabrics or integrated into composite materials.

Core Limitations

- Brittle Nature: Carbon fiber alone is prone to breakage; it must be combined with other materials to enhance structural durability.

Applications

Carbon fiber finds its place in industries demanding lightweight, strong materials:

- Aerospace: Used in aircraft wings, rocket boosters, and missile structures to reduce weight and improve performance.

- Transportation: Sports cars like F1 vehicles leverage carbon fiber to enhance aerodynamics and strength.

- Other Industries: Applications include industrial robots, carbon fiber robotic exoskeleton systems, sports equipment (bicycles, tennis rackets), medical prosthetics, and building reinforcement materials.

What is CFRP (Carbon Fiber Reinforced Polymer)?

Definition

CFRP is CFRP is a composite material where carbon fiber acts as a reinforcing agent embedded in a matrix material like epoxy resin, forming the basis of many load-bearing structures produced through

custom carbon fiber parts manufacturing. This combination boosts strength and alters performance characteristics.

Key Characteristics

Lightweight Advantage:

- CFRP is 50% lighter than steel and 30% lighter than aluminum.

- Boasts a specific strength exceeding 2000 MPa/(g/cm³), far surpassing steel.

Structural Strength:

- High fatigue resistance.

- Can recover strength after load removal (pseudo-plastic effect).

Thermal Properties:

- Retains strength at extreme temperatures (2200°C).

- Low thermal expansion coefficient ensures dimensional stability.

Manufacturing Processes

Traditional Methods:

- Hand Lay-Up Molding: Suitable for custom designs, like sports car bodies.

- Filament Winding: Creates cylindrical structures such as high-pressure tanks.

Modern Techniques:

- RTM (Resin Transfer Molding): Enables mass production, especially for automotive components.

- VARI (Vacuum-Assisted Resin Infusion): Ideal for large structures like aircraft fuselages.

Applications

CFRP has a broader range of functions compared to carbon fiber:

- Aerospace: Builds over one-third of modern aircraft structure (e.g., Boeing 787 fuselage).

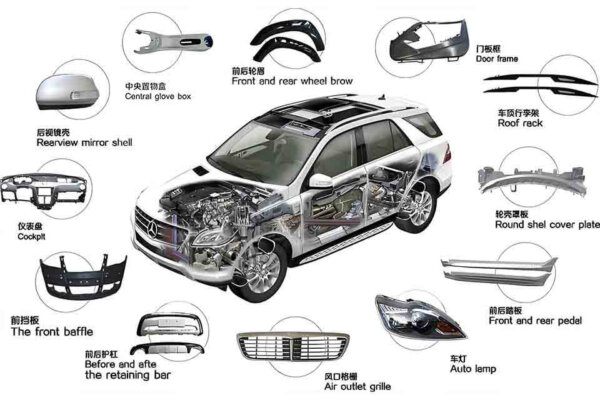

- Automotive: Used extensively in body panels, disc brakes, and interiors.

- Specialized Fields: Nuclear reactor components, solid rocket nozzles, and artificial heart valves benefit from CFRP’s unique properties.

CFRP is also widely used in unmanned aerial vehicles (UAVs), where carbon fiber drone structures rely on CFRP laminates to achieve high stiffness-to-weight ratios, vibration

Carbon Fiber vs CFRP: Core Differences

Comparison Table

| Dimension | Carbon Fiber | CFRP |

|---|---|---|

| Essence | Single material (fiber) | Composite material |

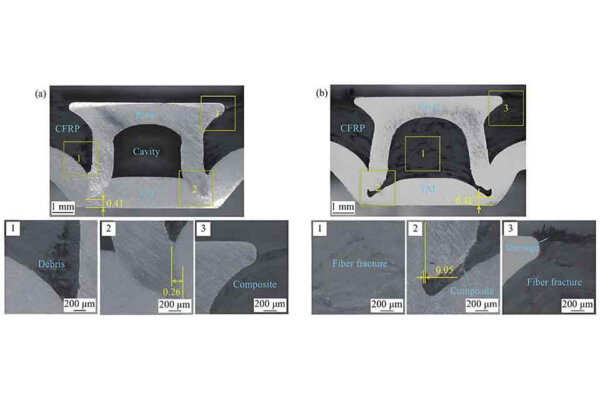

| Mechanical Properties | High strength but brittle | High impact resistance due to matrix |

| Electrical Conductivity | Comparable to metals | Less conductive, requiring added layers |

| Manufacturing Process | High-temperature carbonization | Layering fibers + resin curing |

| Damage Behavior | Shatters completely upon impact | Retains structure; energy absorbed |

| Recyclability | Technically recyclable | Recycling reduces strength by ~30% |

| Functionality | Primarily reinforcement | Final structural application |

Carbon Fiber vs CFRP in Typical Applications

Carbon Fiber Alone

- Non-load-bearing uses:

- Anti-static fabrics and heating elements in satellites.

- Insulation layers for non-structural purposes.

CFRP Applications

Load-Bearing Structures:

- Aircraft fuselage (20% lighter than aluminum).

- F1 crash zones absorb energy during collisions.

Extreme Environments:

- Rocket nozzle linings exhibit high ablation resistance.

- Brake discs withstand intense heat and friction forces.

Carbon Fiber vs CFRP: Cost and Sustainability

Carbon Fiber Cost vs CFRP

Carbon fiber is expensive to produce due to its high-temperature manufacturing process. However, CFRP adds to the cost because it involves combining carbon fiber with a matrix material and requires advanced molding techniques.

Carbon Fiber Recycling vs CFRP

- Carbon Fiber: Easier to recycle as it can be broken down and reused in specific non-critical applications.

- CFRP Recycling: Complicated due to resin curing. Recycling often leads to reduced material quality, making sustainability a key concern.

Advantages and Disadvantages

Carbon Fiber

Pros:

- Extremely lightweight and strong.

- High thermal resistance.

- Electrically conductive.

Cons:

- Brittle when used alone.

- Requires a matrix for structural reliability.

CFRP

Pros:

- Superior strength and durability.

- Resistant to fatigue and impact damage.

- Supports load-bearing applications across industries.

Cons:

- Difficult to recycle.

- Costlier due to resin-related processes.

Use Cases: Carbon Fiber vs CFRP

Carbon Fiber Strength vs CFRP

While carbon fiber provides raw strength, CFRP incorporates impact resistance and energy absorption, making it better for dynamic applications like aircraft and automobiles.

Carbon Fiber in Cars vs CFRP in Cars

Carbon fiber is often woven into vehicle interiors, whereas CFRP forms structural components like body panels, which maintain integrity during high-speed collisions.

Conclusion: The Flour and Bread Analogy

Carbon fiber is the “flour” of the composite material world — a high-quality raw ingredient. Meanwhile, CFRP is the “bread” — a finished product suitable for direct structural applications. By combining carbon fiber with matrix materials, CFRP achieves superior lightweight strength, impact resistance, and thermal stability, revolutionizing industries such as aerospace, automotive, and sports equipment.

For intricate applications requiring load-bearing structures and dynamic performance, CFRP provides unmatched engineering value. However, for cost-efficiency and simpler, non-structural applications, carbon fiber alone can suffice.