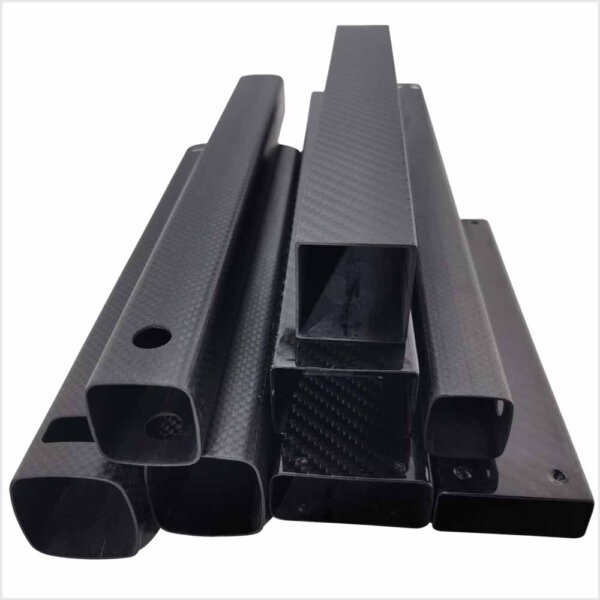

Carbon Fiber Composite Material Hot Pressing Molding Process

Our factory employs an advanced carbon fiber hot press process with a P20 steel mold, ensuring high efficiency, precision, durability, and cost-effectiveness for quality production.

Are you looking for more power and speed in your car? Our custom carbon fiber driveshafts are the answer! We make these at our top carbon fiber product manufacturing plants. Our driveshafts help cars, planes, boats, and racing teams go faster and work better.

We serve many types of customers:

Our carbon fiber driveshafts are lighter, stronger, and better than regular ones. They help your car or machine work at its best.

A carbon fiber driveshaft is a big win for your car. It makes your car go faster and use less gas. The shaft is made from special carbon fiber filaments that are very strong. Our driveshafts are up to 70% lighter than metal ones. This means:

“I put a custom carbon fiber driveshaft in my Mustang, and now it feels like a whole new car! The acceleration is much better.” – Tom R., Race Car Driver

The torque you can send to your wheels is much higher with our driveshafts. They can take more power without breaking. This is why many drag racers pick our parts.

| Feature | Steel Driveshaft | Carbon Fiber Driveshaft |

|---|---|---|

| Weight | 15-20 lbs | 4-8 lbs |

| Torque capacity | Good | Excellent |

| Critical speed | Lower | Higher |

| Vibration | More | Less |

| Life span | 5-7 years | 10+ years |

Our parts work with many cars like BMW, GT, and GT350 models. We can make the right size for your transmission and axle.

We make each driveshaft just for you. Our engineers check what you need and build it right. Each one is wound in-house with our special resin mix. You can pick from:

All our parts are SFI certified for racing. This means they are safe even at high speeds. If something ever goes wrong, our driveshafts don’t shatter like metal ones.

“When I built my S197 Mustang for drag racing, I knew I needed something special for the drivetrain. Your custom carbon fiber driveshafts gave me the edge I needed to win.” – Mike T., Professional Racer

Our balance testing makes sure each shaft runs perfect. No shaking or noise like with aluminum driveshafts.

| Car Type | Best Driveshaft Option |

|---|---|

| Street Cars | Standard Carbon Fiber |

| Track Cars | High-Performance Series |

| Drag Race Cars | Ultra Series with 1480 |

| AWD Systems | CV-Joint Carbon Fiber |

| Mustang/GT | Custom Fit Carbon Fiber |

Our proprietary process makes the best driveshafts. We start with top carbon fiber and add our special mix. Then we:

The bond between the carbon fiber and metal parts is super strong. We use special glue that never comes loose. This is better than steel or aluminum parts that can crack or bend.

Torsional stiffness is much higher with our driveshafts. This means more of your car’s horsepower gets to the wheels. Your driveline works better, and your chassis feels tighter.

“After switching from an aluminum driveshaft to your carbon fiber one, my quarter-mile times dropped by 0.3 seconds. That’s huge in racing!” – Sarah K., Drag Racer

QA1 driveshaft standards are just the start for us. We go beyond to make sure each part is perfect.

| Material | Weight Reduction | Torsional Strength | Critical Speed |

|---|---|---|---|

| Steel | 0% | Base | Base |

| Aluminum | 40% | 15% less | 20% higher |

| Carbon Fiber | 70% | 40% more | 60% higher |

| Our CF | 75% | 60% more | 75% higher |

Ready to feel the power of carbon fiber driveshafts? Our team is ready to help you get the right part for your car or project. We work with:

The process is easy:

All our driveshafts are lighter and stronger than what came in your car. They will last longer too. The durability is amazing. You can order through our website or call us. Our carbon factory has experts ready to help. We also make custom composite parts for many uses.

Check out our work for carbon fiber cars and carbon fiber motorcycles to see what we can do. Our custom carbon fibers page shows even more options.

Don’t wait to upgrade your car or project. Our carbon fiber driveshafts will make a big difference you can feel right away.

Contact us at [email protected]

Phone/Whatsapp: + 86 136 2619 1009

Summary: Our custom carbon fiber driveshafts deliver incredible performance with 70% less weight than steel, higher torque capacity, and smoother operation. Experience faster acceleration, better fuel economy, and increased durability – all with perfect fitment for your specific vehicle.

Our factory employs an advanced carbon fiber hot press process with a P20 steel mold, ensuring high efficiency, precision, durability, and cost-effectiveness for quality production.

Our factory runs 100+ hot pressure autoclaves, using aluminum molds and vacuum induction to shape carbon fiber with precision. High heat and pressure enhance strength, stability, and flawless quality.

Our Carbon Fiber Research Center drives innovation in new energy, intelligence, and lightweight design, using advanced composites and Krauss Maffei FiberForm to create cutting-edge, customer-focused solutions.

Here are the answers to the frequently asked questions from the experienced carbon fiber products factory

We produce a wide range of carbon fiber components, including automotive parts, motorcycle parts, aerospace components, marine accessories, sports equipment, and industrial applications.

We primarily use high-quality prepreg carbon fiber and large-tow carbon fiber reinforced high-performance composites to ensure strength, durability, and lightweight characteristics.

Yes, our products are coated with UV-protective finishes to ensure long-lasting durability and maintain their polished appearance.

Yes, our facilities and equipment are capable of producing large-size carbon fiber components while maintaining precision and quality.

What are the benefits of using carbon fiber products?

Carbon fiber offers exceptional strength-to-weight ratio, corrosion resistance, stiffness, thermal stability, and a sleek, modern appearance.

We cater to automotive, motorcycle, aerospace, marine, medical, sports, and industrial sectors with a focus on lightweight and high-performance carbon fiber components.

Yes, we provide custom carbon fiber solutions tailored to your specifications, including unique designs, sizes, and patterns.

We utilize advanced technologies such as autoclave molding, hot pressing, and vacuum bagging, ensuring precision, stability, and quality in every product. wonders with the Hello Elementor Theme, we’re trying to make sure that it works great with all the major themes as well.

We use aluminum and P20 steel molds, designed for durability and high accuracy, to create complex and precise carbon fiber components.

Our products undergo rigorous quality control checks, including dimensional accuracy, material integrity, and performance testing, to meet industry standards.