Can You Bend Carbon Fiber? Guide to Shaping & Real-world Use

The Short Answer

Yes, you can bend carbon fiber. But you need special tools and know-how to do it right. How you bend it depends on the fiber direction, resin type, and bending method.

The Problem: Why Bending Carbon Fiber Is Hard

Many people think carbon fiber is too stiff to bend. This causes big problems:

- Wasted materials from failed bending attempts

- Broken parts that cost a lot of money

- Design limits that stop cool ideas

- High costs from complex molds Some shops try to bend carbon fiber and break it. Others just say “no” to making curved parts. This means you can’t get the cool carbon fiber parts you want.

“We couldn’t find anyone who could make our curved carbon fiber design until we found .” – Happy Customer

The Science of Bending Carbon Fiber

Types of Carbon Fiber

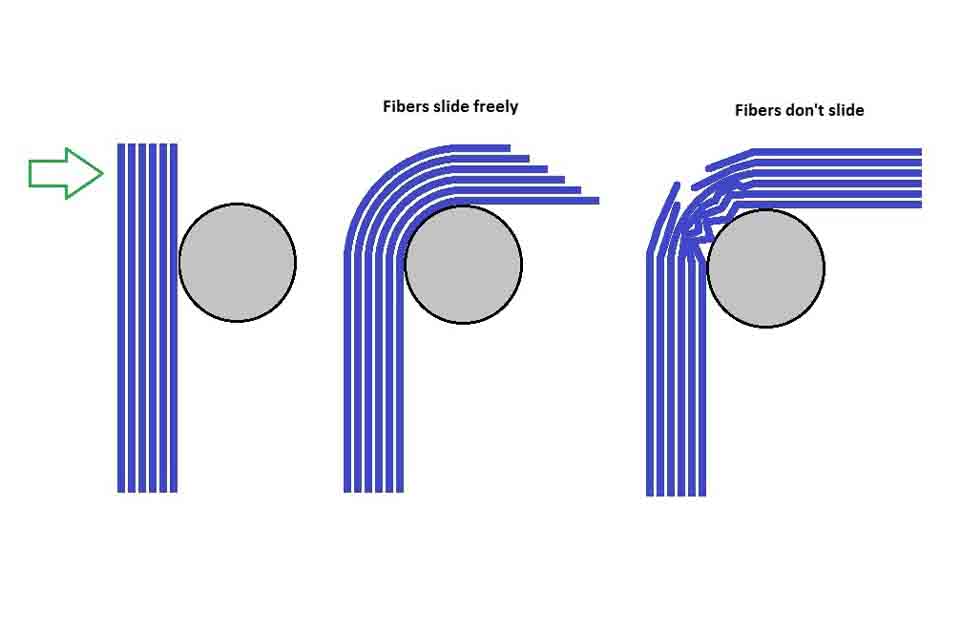

Not all carbon fiber bends the same way. Here’s why: Unidirectional fibers all go one way. They bend well in one direction but break easily in others. Woven fibers go in many ways. They don’t bend as much but are stronger.

| Fiber Type | Bending Ease | Strength After Bending |

|---|---|---|

| Unidirectional | High in one direction | Medium |

| Plain Weave | Medium | High |

| Twill Weave | Good | Very High |

Resin Matters Too

The glue that holds carbon fibers together is called resin. Thermoset resins get hard when heated and stay hard. They’re hard to bend after they cure. Thermoplastic resins can melt and harden many times. They’re better for bending.

How To Bend Carbon Fiber (Methods)

1. Thermal Reshaping

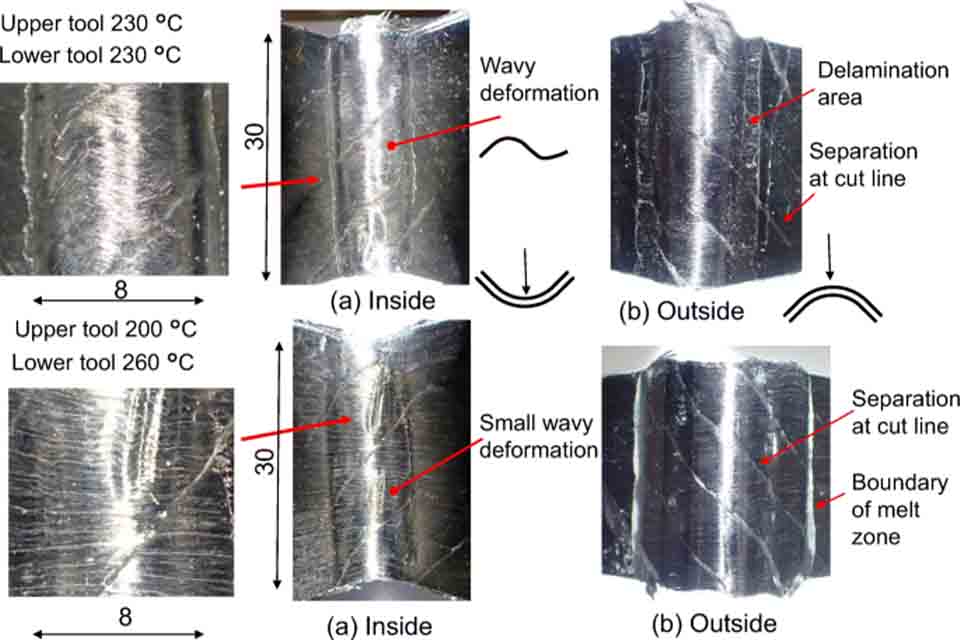

This is how we bend already cured carbon fiber:

- Heat the carbon fiber to 250-400°F

- Bend it to the shape you want

- Hold it there until it cools

- Re-cure it for best strength Warning: If you don’t re-cure, your part might lose up to 15% of its strength!

2. Pre-Cure Bending (Best Method)

At China Carbon Fibers, we prefer this method:

- Lay wet carbon fiber on a mold

- Shape it how you want

- Let it cure in that shape

- Get maximum strength This way makes stronger parts with perfect curves.

3. Design for Flexibility

Some parts need to flex a bit. We can make carbon fiber that bends on purpose:

- Curved-wall honeycomb designs

- Hybrid materials (carbon fiber + other stuff)

- Special fiber directions for controlled flex

The Agitation: What Happens When Carbon Fiber Bending Goes Wrong

Bad bending leads to big problems:

- Cracks that you can’t see

- Weak spots that break later

- Ugly parts that look bad

- Wasted money on ruined materials One customer came to us after trying to bend carbon fiber on their own. They ruined $5,000 worth of material! Global data shows 14.8% drop in carbon fiber use (from 135,000 tons to 115,000 tons) partly due to wasted material from bad manufacturing.

The Solution: Expert Carbon Fiber Bending

At our carbon fiber factory, we know how to bend carbon fiber the right way. Here’s what we do:

- Study your design

- Pick the right fiber type

- Choose the best resin

- Create custom molds

- Control the cure process

- Test the strength The result? Perfect curved carbon fiber parts every time.

Applications of Bent Carbon Fiber

Automotive Parts

We make carbon fiber car parts with perfect curves:

- Dashboards that fit just right

- Fenders with smooth curves

- Hoods that look amazing

- Spoilers with exact angles Cars with our carbon fiber parts are up to 30% lighter than those with steel parts. This means better gas mileage and faster speeds.

Motorcycle Components

Our carbon fiber motorcycle parts have complex curves that others can’t make:

- Gas tanks with perfect fit

- Side panels that look great

- Fenders that keep weight low

- Chain guards that protect well Riders love how our parts make their bikes lighter and better looking.

Sports Equipment

We bend carbon fiber for:

- Bicycle frames with special shapes

- Helmets that fit heads better

- Racing seats with body curves

- Golf club shafts with perfect flex Sports gear made with our bent carbon fiber is 50% stronger than metal but much lighter.

When to Avoid Bending Carbon Fiber

Some parts should not be bent:

- Main load-bearing structures where any weakness is bad

- Safety equipment that must be perfect

- Parts already cured without pro help Instead, let us make these as custom carbon fiber parts from the start.

How We Make Bent Carbon Fiber Parts

Our process is better than others:

- Design Phase

- We study your needs

- We make 3D models

- We plan the fiber direction

- Material Selection

- We pick the right carbon fiber type

- We choose the best resin

- We test small samples

- Mold Creation

- We make perfect molds

- We check all curves

- We add texture if needed

- Manufacturing

- We lay fiber by hand or machine

- We cure in controlled ovens

- We check quality at each step

- Testing

- We test strength

- We check looks

- We make sure it fits

Customer Success Stories

Race Car Team Saves Weight

A racing team needed curved carbon fiber parts that were strong but light. Other shops said it couldn’t be done. We made their curved parts with our special bending methods. Their car was 42 pounds lighter and won its next race!

Motorcycle Builder Gets Perfect Fit

A custom bike builder tried five other carbon fiber shops. None could make the gas tank shape he wanted. We used our pre-cure bending method to create a perfect fit. His bike won “Best in Show” and now he only uses our carbon fiber.

Aircraft Company Cuts Costs

An aircraft part needed complex curves but had to be super strong. The old way cost $12,000 per part. Our bending technique made the same part for $7,200 and it passed all strength tests.

Carbon Fiber Market Trends (2022-2025)

| Year | Global Demand (tons) | Recycled CF Use | Energy Use (MJ/kg) |

|---|---|---|---|

| 2022 | 135,000 | 12% | 250-300 |

| 2023 | 115,000 | 18% | 220-280 |

| 2025 (Expected) | 130,000+ | 25-30% | Under 200 |

These numbers show that carbon fiber use is growing again after a short drop. More people want bent and curved carbon fiber parts.

Our Sustainable Bending Approach

We care about the earth too. Our bending methods:

- Use 40% less energy than standard methods

- Create 85% less waste

- Let us use more recycled carbon fiber Our new lignin-based carbon fiber reduces oil use by 60% and still bends perfectly.

Why Choose Us For Your Bent Carbon Fiber Needs

- Expert Knowledge

- 15 years bending carbon fiber

- Engineers who understand curves

- Perfect results every time

- Better Equipment

- Custom bending tools

- Computer-controlled ovens

- Precision molds

- Lower Costs

- Less waste means savings for you

- Faster production times

- Longer-lasting parts

- More Options

- Any curve you can imagine

- Mix of materials if needed

- Custom finishes and colors

How to Order Bent Carbon Fiber Parts

Getting perfect bent carbon fiber parts is easy:

- Contact us with your idea

- Send drawings or samples

- Get a fast quote

- Approve our design plan

- Receive perfect parts We make everything from small carbon fiber phone cases to huge car parts with complex curves.

DIY Carbon Fiber Bending Tips

Want to try at home? Here are safe tips:

- Start with flat carbon fiber sheets for practice

- Use gentle heat (hair dryer level)

- Bend very slowly

- Don’t expect perfect results first try But remember: for important parts, trust the experts (us!).

FAQ About Bending Carbon Fiber

Can you bend cured carbon fiber?

Yes, but it’s hard. Heat helps. Expect 15-30% strength loss unless you re-cure it. We know how to do this right.

What tools cut curved carbon fiber?

Diamond-coated tools work best. We have special ones that don’t fray the edges.

Is bent carbon fiber weaker?

When done wrong, yes. When done by us, our parts keep over 90% of their strength.

How much does custom curved carbon fiber cost?

It depends on size and shape. But our methods save money and give better results. Contact us for a quote!

Key Takeaways

- Carbon fiber can bend if you know how

- Pre-cure bending is best for strength

- Fiber direction matters a lot

- Professional help saves money and time

- Our carbon fiber products have the best curves

Contact Us For Perfect Bent Carbon Fiber

Don’t struggle with bending carbon fiber. Let the experts handle it. Our team makes perfect curved parts every day.

Call us: +86 136 2619 1009

Email: [email protected]

Visit: https://chinacarbonfibers.com

Tell us what you need, and we’ll bend carbon fiber into the perfect shape for you!