How Are Carbon Fiber Parts Made: A Complete Guide

The Problem: Making Strong Parts That Don’t Weigh Too Much

Do you want parts that are strong but not heavy? Many people do! Cars, bikes, and planes need light parts that don’t break. But most light things are not strong. And most strong things are too heavy. This is a big problem! When you make things from metal, they get too heavy. This makes cars use more gas. It makes planes hard to fly. It makes bikes hard to ride.

The Problem Gets Worse

Think about what happens when parts are too heavy:

- Cars use more gas or battery power

- Bikes are hard to ride up hills

- Sports gear feels slow

- Planes need more fuel And if you try to make metal parts thinner to save weight, they get weak and can break! This is very bad for safety. No one wants parts that break!

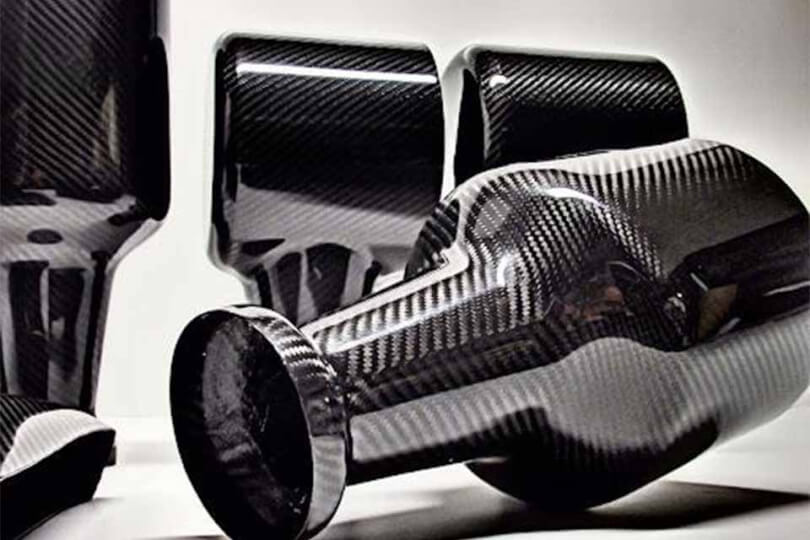

The Solution: Carbon Fiber Manufacturing

Carbon fiber fixes these problems! Our company makes custom carbon fiber parts that are both light AND strong. We can make any part you need with our OEM/ODM service. to see what we can do!

What Is Carbon Fiber?

Carbon fiber is tiny threads of carbon that are thinner than a hair. These threads are stronger than steel but much lighter!

The global carbon fiber market is growing fast! In 2021, the world could make 193,000 tons of carbon fiber.

How We Make Carbon Fiber Parts: Step By Step

Step 1: Fiber Preparation

First, we get the carbon fibers ready. These come on big rolls. We cut them to the right size and shape for your part.

Step 2: Layup Techniques

Next comes the layup. This is when we put the carbon fiber where it needs to go. We do two kinds of layup:

- Hand layup – For custom parts that need special care

- Machine layup – For making many parts the same way Our skilled workers know just how to place each fiber for the most strength.

Step 3: Molding Methods

We use different ways to mold your parts:

| Method | What It’s Good For | How Fast It Is |

|---|---|---|

| C-RTM | Car parts | Very fast – good for making many parts |

| Vacuum bagging | Custom shapes | Medium speed – good for special projects |

| Autoclave | Airplane parts | Slow but perfect – when quality must be the best |

| Our C-RTM method is very good for car parts, just like they use in Yokohama, Japan. |

Step 4: Curing & Finishing

After molding, we cure the parts. This means we make them hard and strong. Then we make them smooth and pretty. We check every part to make sure it’s perfect.

Why Our Carbon Fiber Parts Are Better

Our manufacturing is the best because:

- We use new machines that work better

- Our workers have lots of practice

- We check everything many times

- We can make any shape you want

- We make parts faster than other companies See our custom carbon fiber options for more!

Carbon Fiber Uses By Industry

Cars

Car makers love carbon fiber! It makes cars lighter so they use less gas or battery. By 2025, about 35% of all carbon fiber will go into cars. Our carbon fiber car parts are perfect for making cars better! We make many car parts:

- Hoods

- Doors

- Dashboards

- Spoilers For luxury cars like Bentley, we make special parts that look beautiful.

Motorcycles

Motorcycles need to be light to go fast. Our carbon fiber motorcycle parts help bikes go faster and look cooler. We make:

- Gas tanks

- Side panels

- Fenders

- Exhaust covers

Sports Equipment

Sports gear needs to be strong but light. We make:

- Bike frames

- Tennis rackets

- Golf clubs

- Fishing rods

Airplanes

Airplanes save fuel when they use carbon fiber. We make parts that help planes fly farther using less fuel. By 2025, about 25% of carbon fiber will be used in airplanes.

Our Manufacturing Process In Detail

Raw Materials We Use

We start with the best materials:

- Carbon fiber cloth from Japan

- Special glue that holds it all together

- Color dyes for making parts look nice

How We Shape The Carbon Fiber

- We put the carbon cloth on a mold

- We add special glue

- We press it all together

- We use heat to make it hard

- We make it smooth and shiny

Custom Carbon Fiber Dashboard Example

Want to see how we work? Let’s look at a custom carbon fiber dashboard we made:

- Customer sent us the shape they wanted

- We made a perfect mold

- We put carbon fiber on the mold

- We made sure it was the right thickness

- We cured it in our special oven

- We made it smooth and shiny

- We sent it to the happy customer!

Why Choose Our Carbon Fiber Manufacturing?

We Save You Money

- We make parts faster so you pay less for work time

- Our parts are better so they don’t break (no need to buy twice!)

- We use less material because we know how to make parts right

We Make Parts Fast

- Our new machines work very fast

- We have many workers to do jobs at the same time

- Our smart system keeps track of every job

We Make Any Shape You Need

- Simple shapes like flat panels? No problem!

- Hard shapes with curves? We can do that too!

- Strange shapes that no one has made before? We love a challenge!

The Future Of Carbon Fiber Manufacturing

The future looks bright for carbon fiber! New ways to make it will make it cheaper and better:

- Japan will see 6.3% growth each year from 2025 to 2035

- Wind energy needs for carbon fiber will grow 20% each year

- New methods will use 70% less energy to make carbon fiber

Work With Us Today!

Don’t let heavy, weak parts slow down your products! Our carbon fiber manufacturing can give you the strong, light parts you need. Call us today to talk about your project. We can make a plan just for you. Remember:

- Metal parts = Heavy and old-fashioned

- Plastic parts = Can break easily

- Carbon fiber parts = Light, strong, and modern! Be smart. Choose carbon fiber. Choose us.